A Variable Frequency Drive (VFD) is an adjustable-speed drive that controls AC motor speed and torque by varying input frequency and voltage. It offers advantages such as controlled acceleration, energy savings, and reduced maintenance costs but may have high upfront costs and can cause resonance issues. Proper selection involves considering factors like operating voltage, horsepower rating, and enclosure type.

![What Is a VF D?

[1 ]

◎ A type of adjustable-speed drive

◎ Vary motor input frequency and voltage <=> C ontrol AC

motor output speed & torque

◎ Part of “electro-mechanical” drive systems

2

https://en.wikipedia.org/wiki/Variable -frequency_ drive [1 ]

Also known as

Adjustable

Frequency

Drive (AFD)

Variable -

Voltage

/Variable

- Frequency

(VVVFD)

Variable

S peed Drive

(VSD)

AC Drive

Micro Drive

Inverter Drive](https://image.slidesharecdn.com/vfd-200824064530/75/Variable-Frequency-Drives-2-2048.jpg)

![Need

[2]

C ontrolled S tarting

C urrent

Reduced Power Line

Disturbances

Lower Power Demand

on S tart

Adjustable Operating

S peed

Adjustable Torque

Limit

3

S peed C ontrol Is one of the primary advantages of switching to VF Ds. VF Ds allow motor speeds

to be ramped up and ramped down ensuring connected load is aintained at the required speeds with

necessary energy utilization.

C ontrolled

Acceleration

C ontrolled S topping E nergy S avings Reverse Operation

E liminates Use of

Mech. Drive

C omponents https://www.wolfautomation.com/blog/benefits -vfd/ [2]

https://www.paddockindustries.com/wp-content/uploads/201 7/05/Why-Variable-F requency-Drive-F inal-2-1 6-

1 1 .pdf[3]

Lower Maintenance

C osts

[3]

Longer Motor Life

[3]](https://image.slidesharecdn.com/vfd-200824064530/75/Variable-Frequency-Drives-3-2048.jpg)

![What Is a VF D? - S chematic & Internal C onstruction[4]

4

https://www.youtube.com/watch? reload=9&v=3-cs 4eE iB Wo [4]](https://image.slidesharecdn.com/vfd-200824064530/75/Variable-Frequency-Drives-4-2048.jpg)

![What Is a VF D? - S chematic & Internal C onstruction[4]

5](https://image.slidesharecdn.com/vfd-200824064530/75/Variable-Frequency-Drives-5-2048.jpg)

![Motor S tarter C ircuit - Direct-On-L ine (DOL )

6

[5]](https://image.slidesharecdn.com/vfd-200824064530/75/Variable-Frequency-Drives-6-2048.jpg)

![Motor S tarter C ircuit - S tar Delta

7

[6]](https://image.slidesharecdn.com/vfd-200824064530/75/Variable-Frequency-Drives-7-2048.jpg)

![Manual Motor S tarting

Other S tarters [4]

8

Magnetic Motor S tarting

Primary Resistor S tarting

Auto Transformer S tarting

S C R S tarting /S oft S tarting

https://www.youtube.com/watch? reload=9&v=3-cs 4eE iB Wo [4]](https://image.slidesharecdn.com/vfd-200824064530/75/Variable-Frequency-Drives-8-2048.jpg)

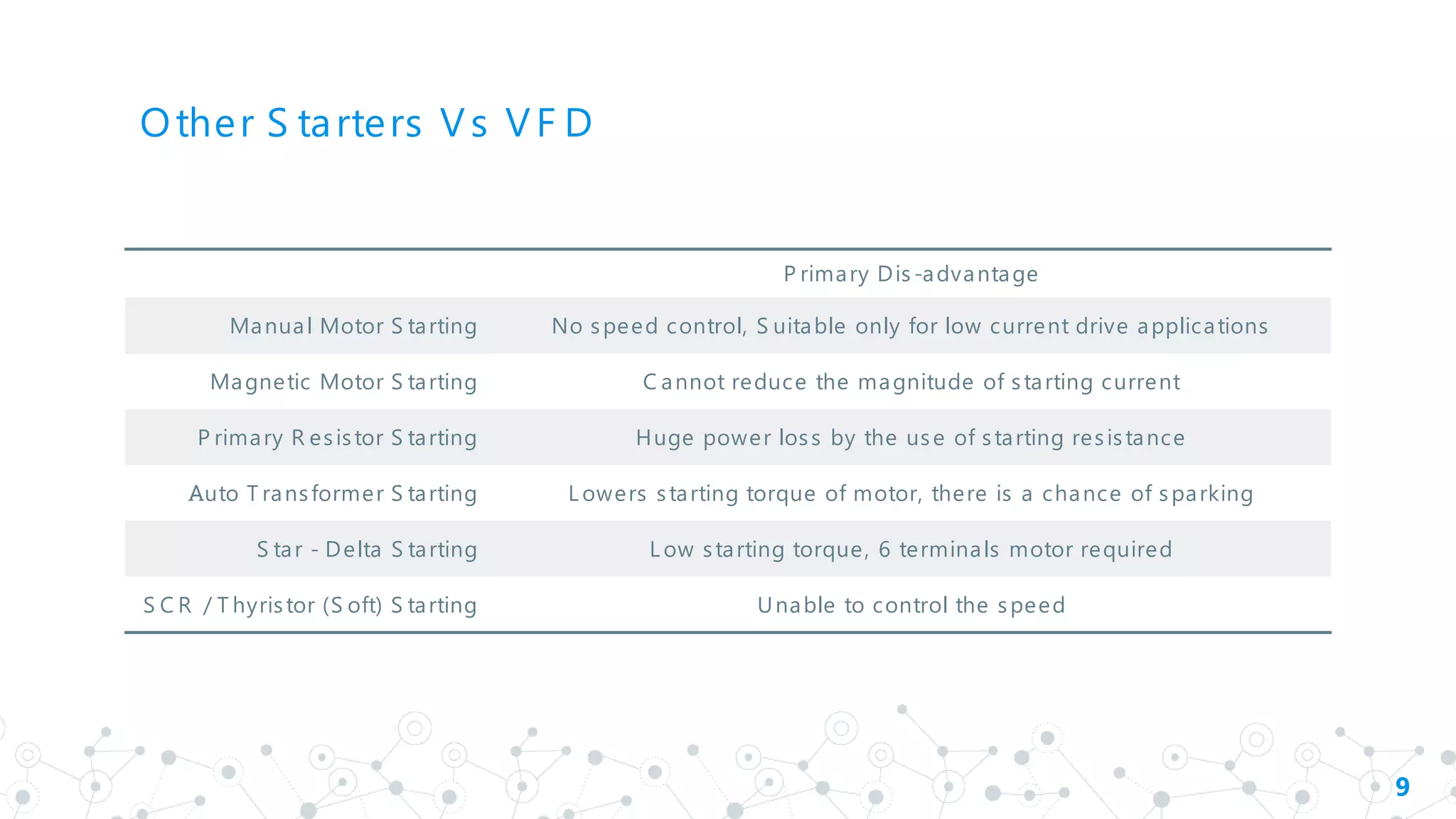

![Allen Bradley VF D - Power F lex 4M S eries

Parameter Configuration

18

No. Parameter

Min / Max

Value

Display/Options

Default

Value

P101 [Motor Nameplate Volts]

20 to Drive

Rated Volts

1 VAC

Based on

Drive Rating

P102 [Motor Nameplate Hertz] 10 to 400 Hz 1 Hz 60 Hz

P103 [Motor Overload Current]

0.0 to (Drive

Rated Amps x2)

0.1 Amps

Based on

Drive Rating

P104 [Minimum Frequency] 0.0 to 400 Hz 0.1 Hz 0.0 Hz

P105 [Maximum Frequency] 0.0 to 400 Hz 1 Hz 60 Hz

P106 [Start Source] 0 to 5

Keypad, 3 Wire, 2 Wire, 2 Wire

Level Sensor, 2 Wire High

Speed, Communication Port

0

P107 [Stop Mode] 0 to 7

Ramp, Coast, DC Brake, DC

Brake Auto

0

P108 [Speed Reference] 0 to 5

Drive Potentiometer, Internal

Frequency, 0-10V input, 4-

20mA input, Preset Frequency,

Communication Port

0

P109 [Acceleration time 1] 0.0 to 600 Secs 0.1 Secs 10.0 Secs

P110 [Deceleration time 1] 0.0 to 600 Secs 0.1 Secs 10.0 Secs

P111

[Motor Overload

Retention]

0 or 1 0 = Disabled 1= Enabled 0

P112 [Reset To Defaults] 0 or 1 0 = Idle State 1 = Reset Defaults 0

No. Parameter Min/max Value Display/Options

Default

Value

D001

The Output Frequency

Present at T1,T2 & T3.

0.0 to (P105)

Maximum Freq

0.1 Hz Read Only

D003

The Output Current present

at T1,T2 & T3.

0.0 to (Drive

Rated Amps x2)

0.01 Amps Read Only

D004

Output voltage present at

terminals T1, T2 & T3

0 to Drive Rated

Volts

0.1 VAC Read Only

D020

The present value of the

voltage at I/O Terminal 13

(100.0% = 10 volts).

0.0 to 100.0% 0.1% Read Only

D022

Present operating

temperature of the drive

power section.

0 to 120 degC 1 degC Read Only

No. Parameter Min/max Value Display/Options

Default

Value

T212

Sets analog input level

corresponding to P105 - if a

0-10V input is used by P108

0.0 to 100.0% 0.1% 100.0%

T221

Sets condition that changes

state of o/p relay contacts.

0 to 13 0 = Ready/Fault 0

No. Parameter Min/max Value Display/Options

Default

Value

A434

A442](https://image.slidesharecdn.com/vfd-200824064530/75/Variable-Frequency-Drives-18-2048.jpg)