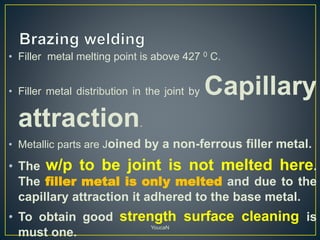

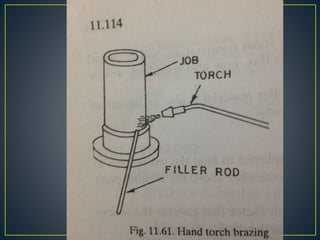

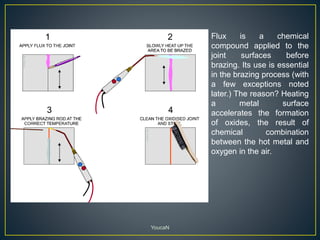

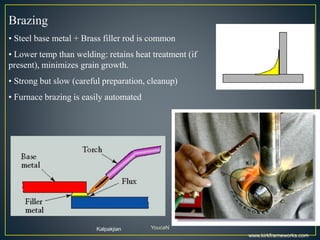

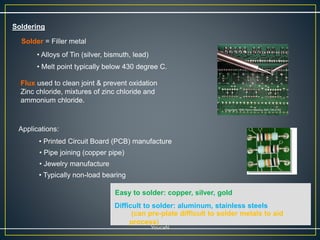

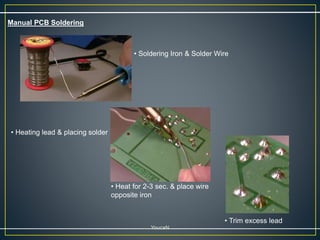

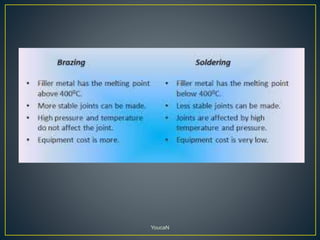

The document discusses brazing and soldering processes. It states that brazing uses filler metals with melting points above 427°C to join metallic parts, while fluxes are used to remove oxides. Common filler metals include copper alloys and silver. Soldering uses tin-based alloys with melting points below 430°C without melting the base metals. Fluxes are also used to clean the joint area. Applications of brazing and soldering include joining pipes/tubes, manufacturing heat exchangers, and electronics/jewelry work.