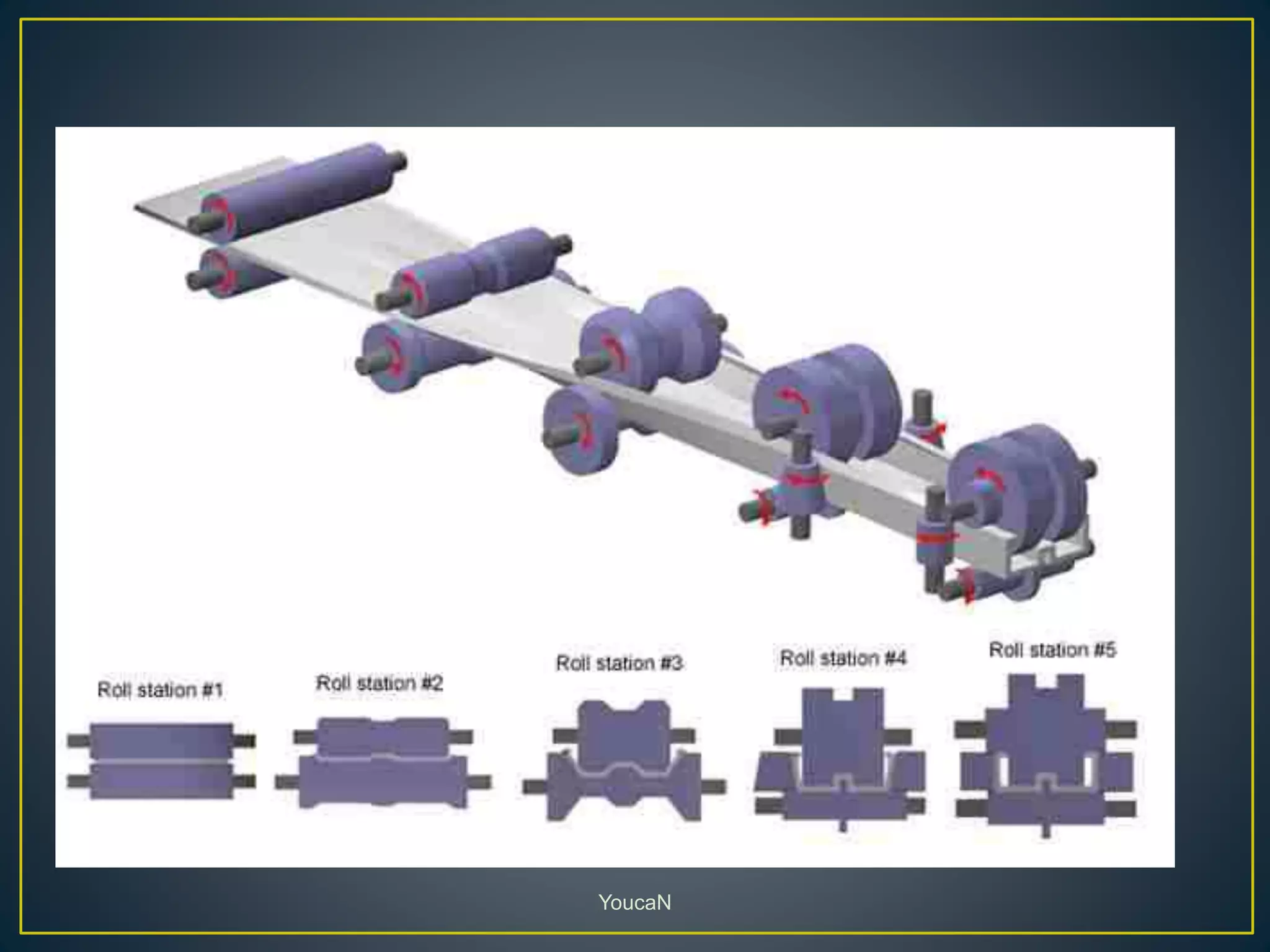

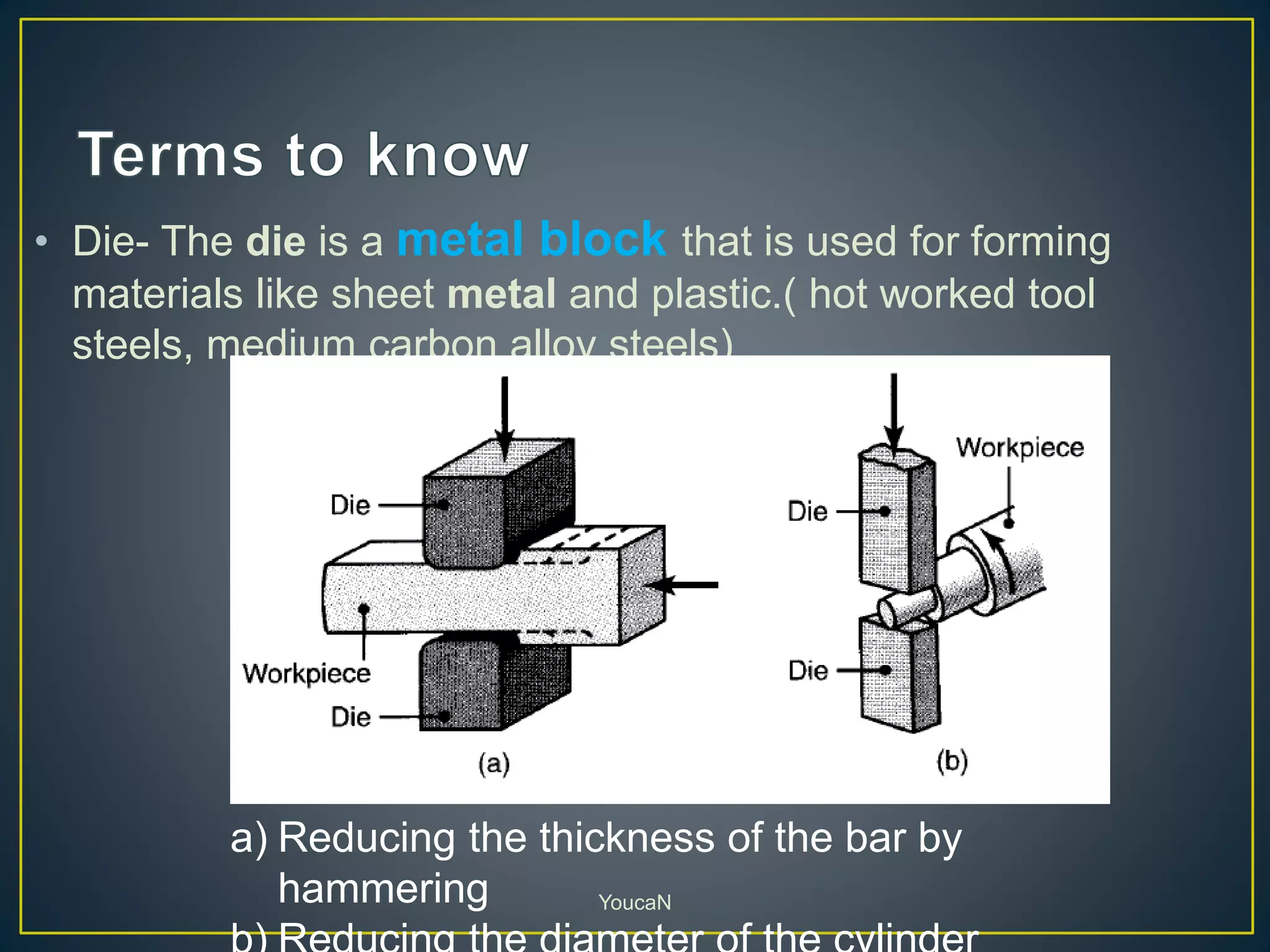

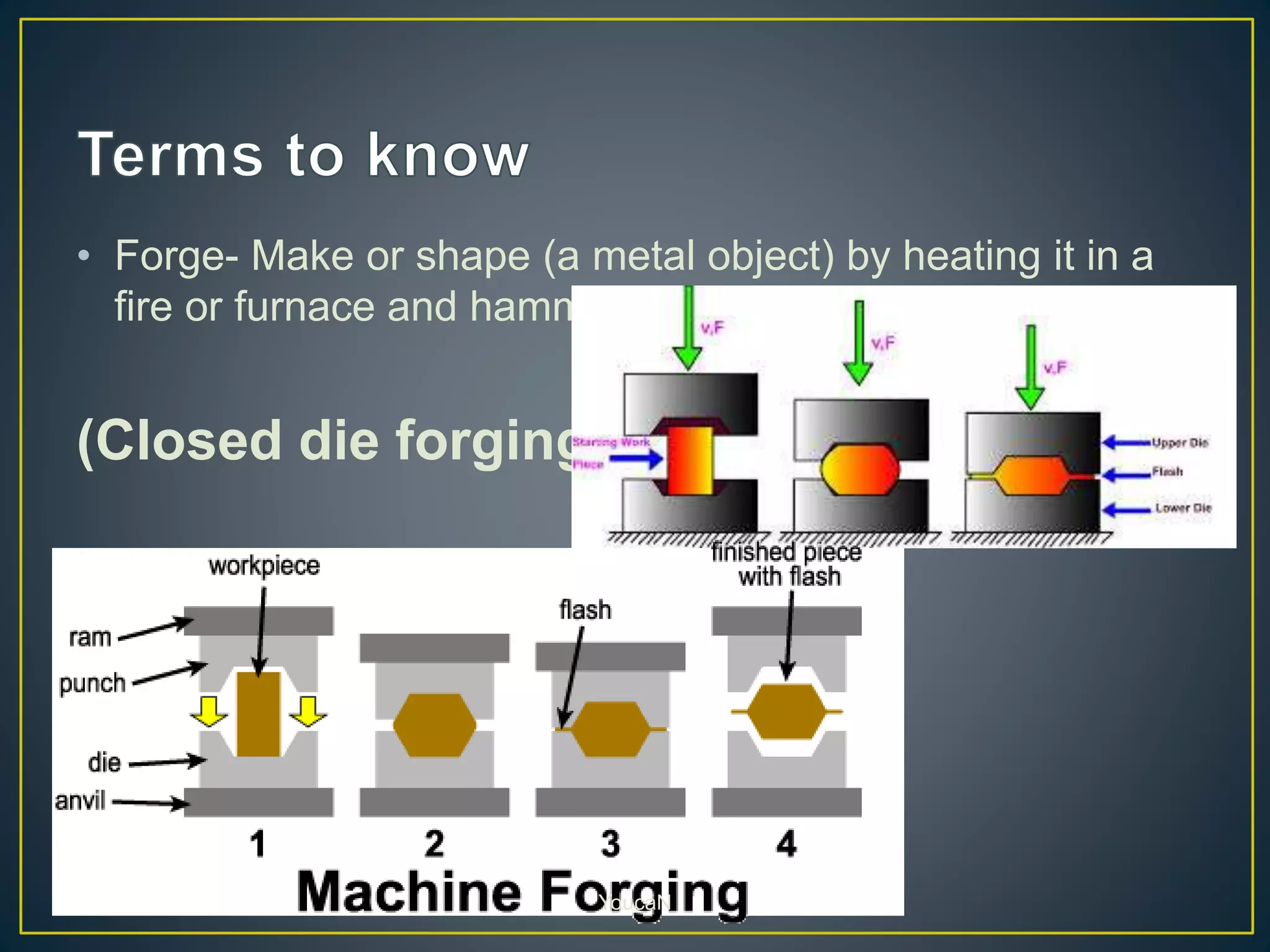

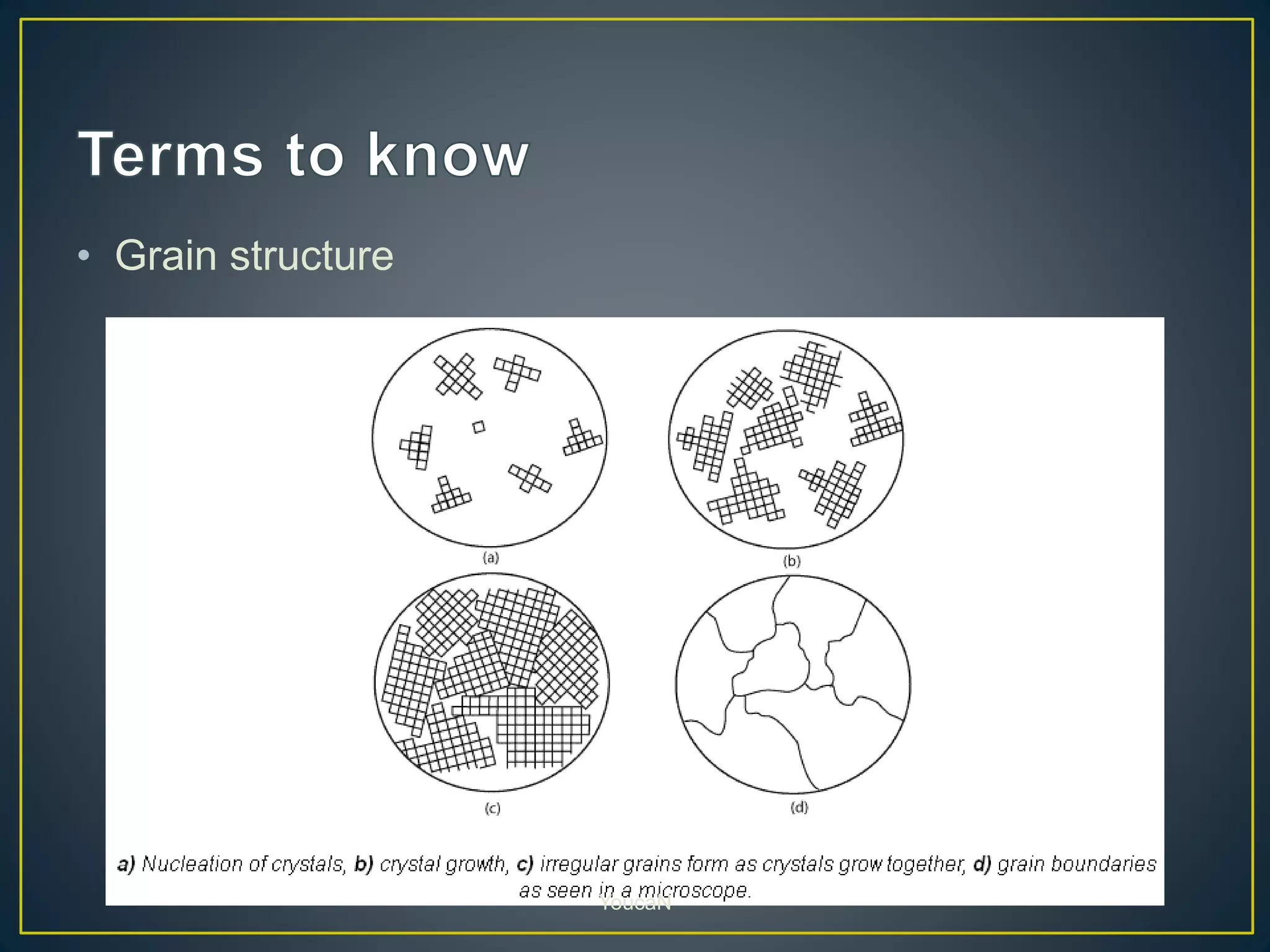

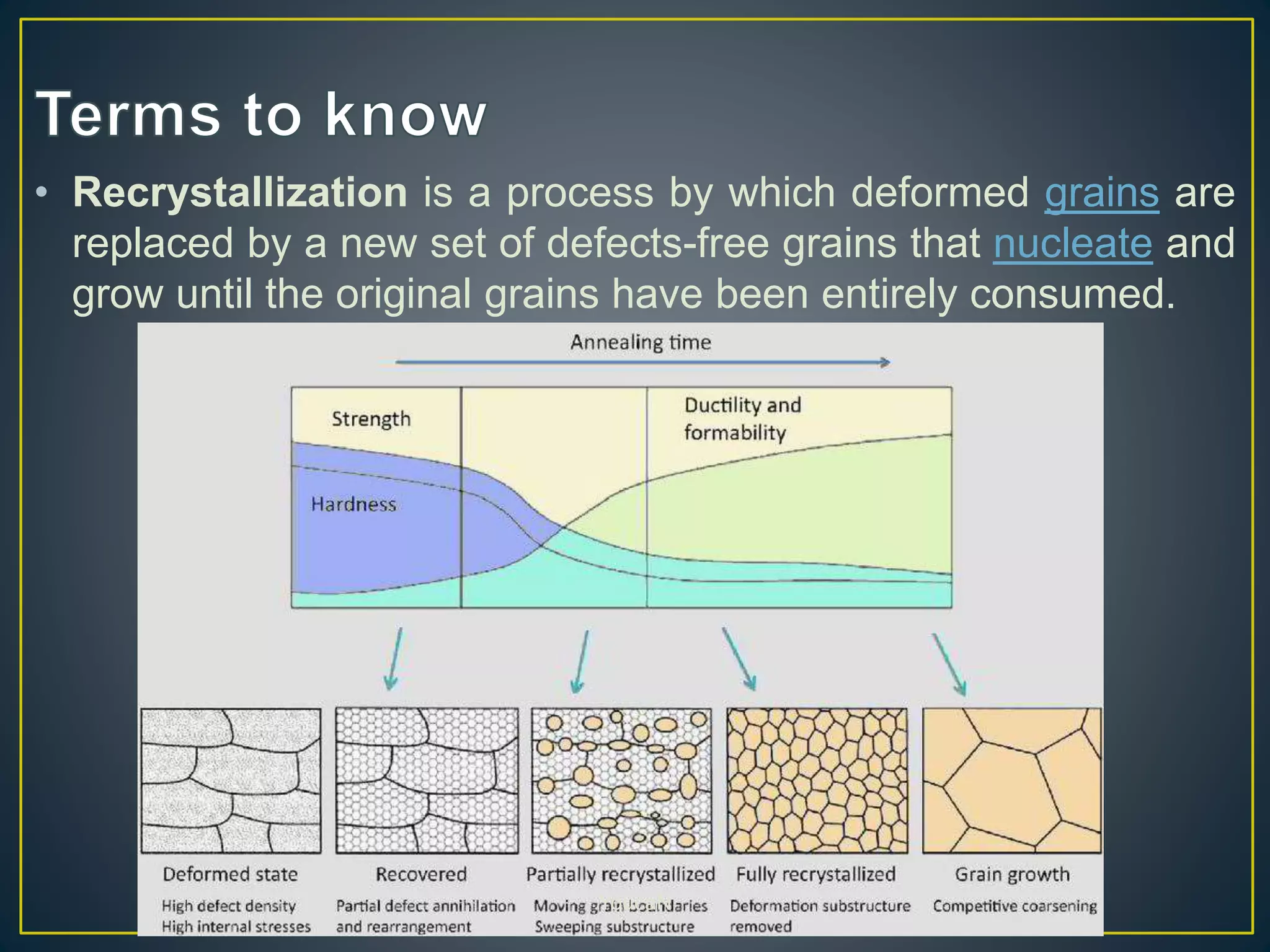

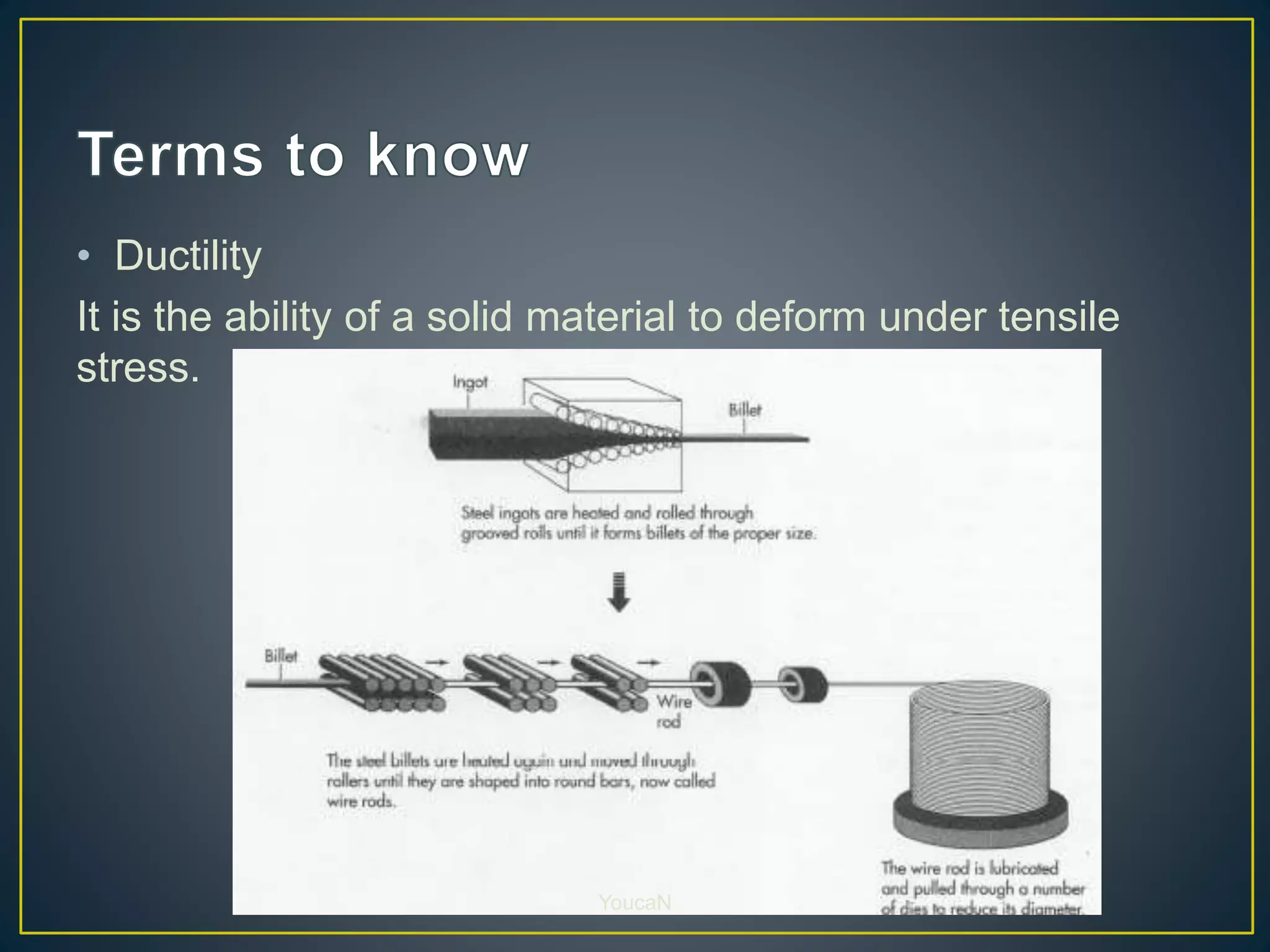

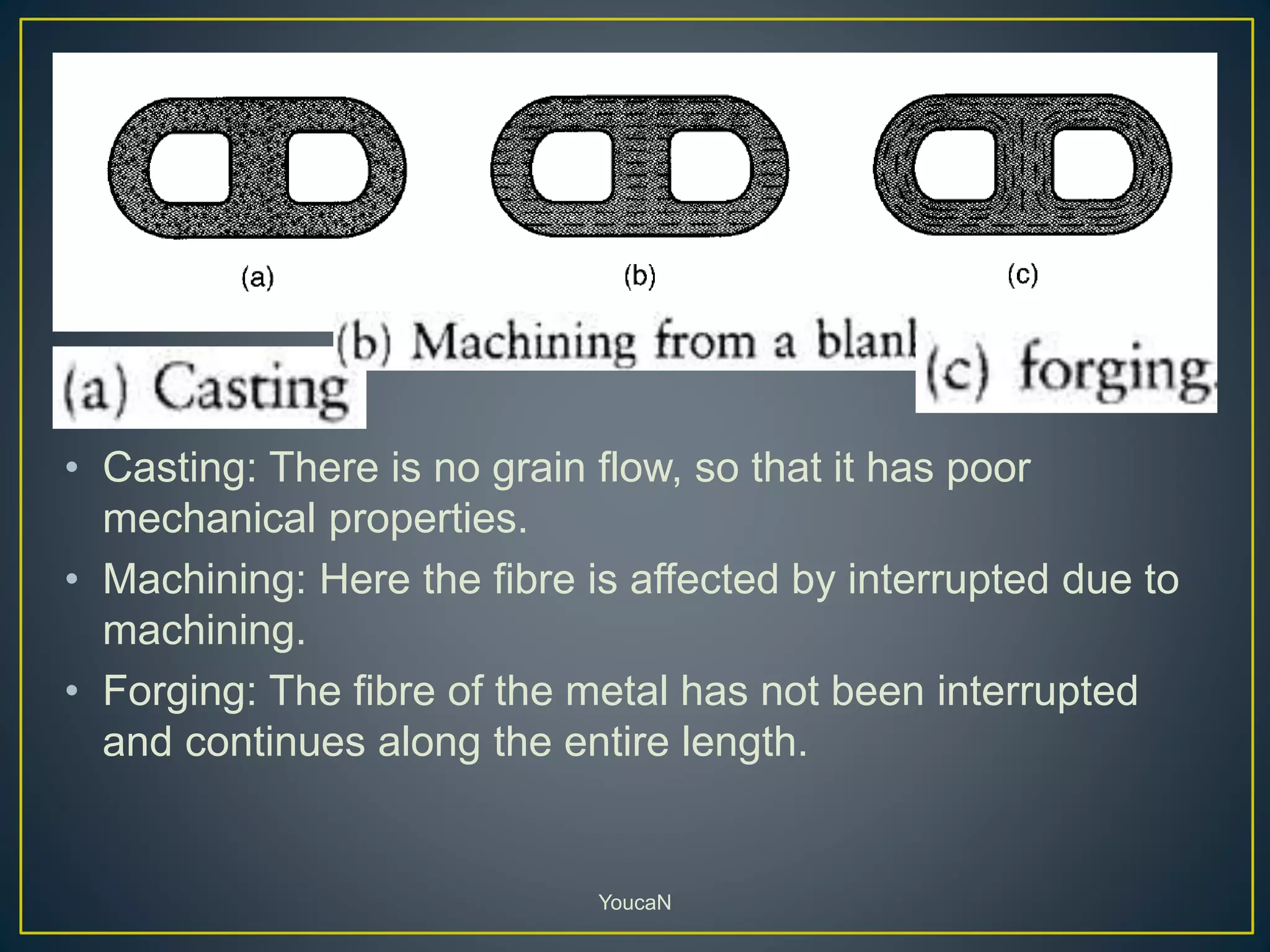

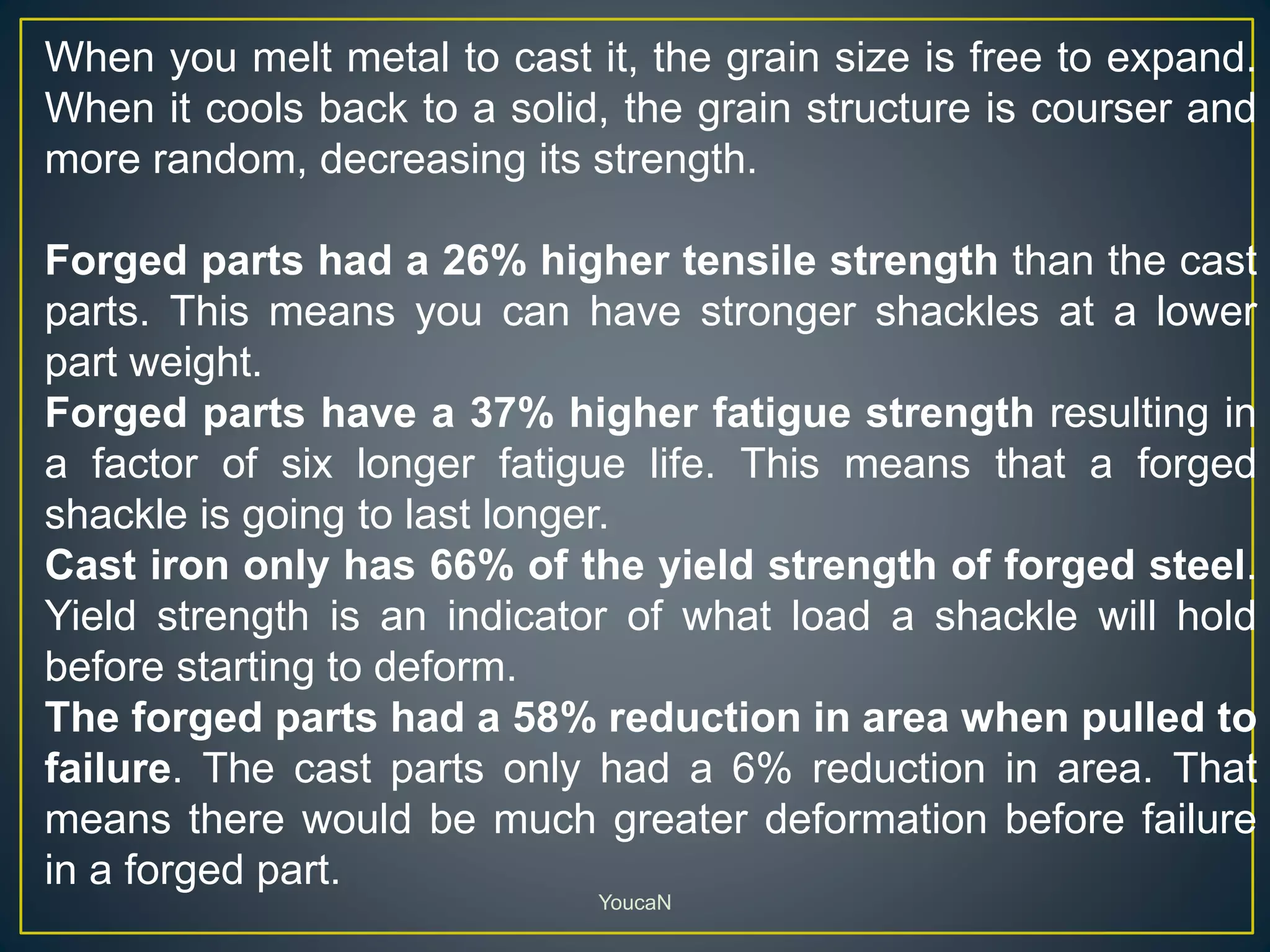

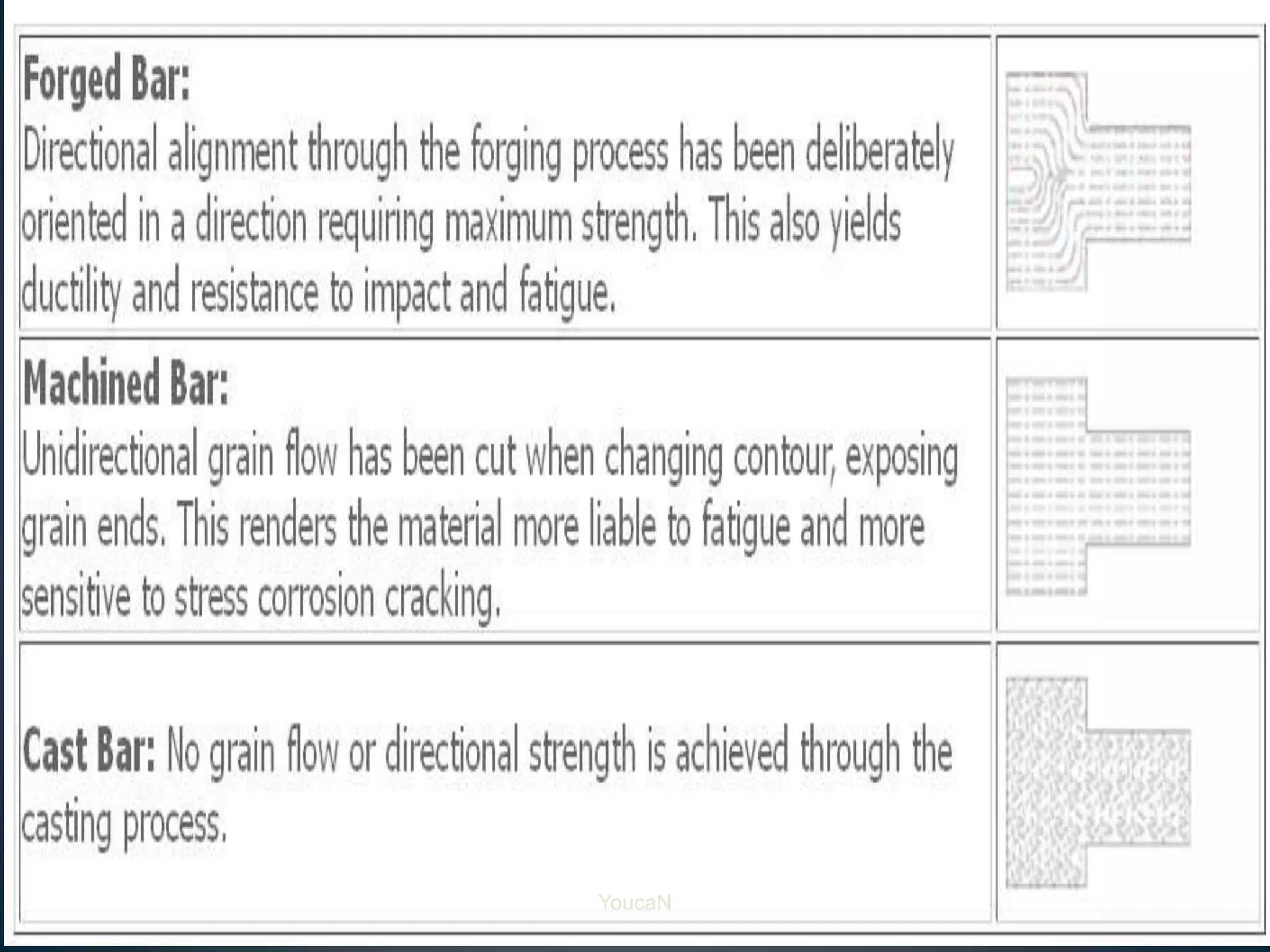

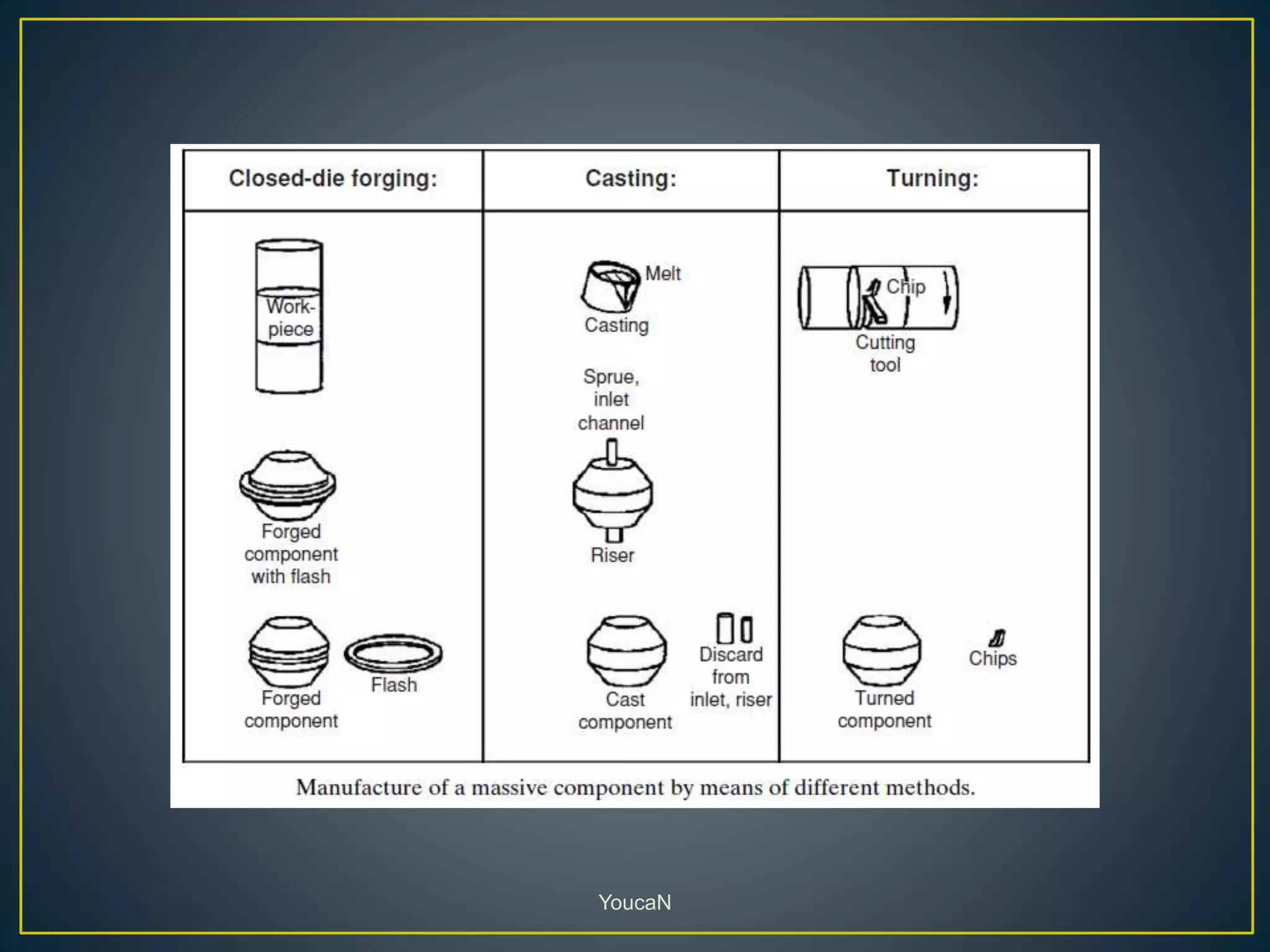

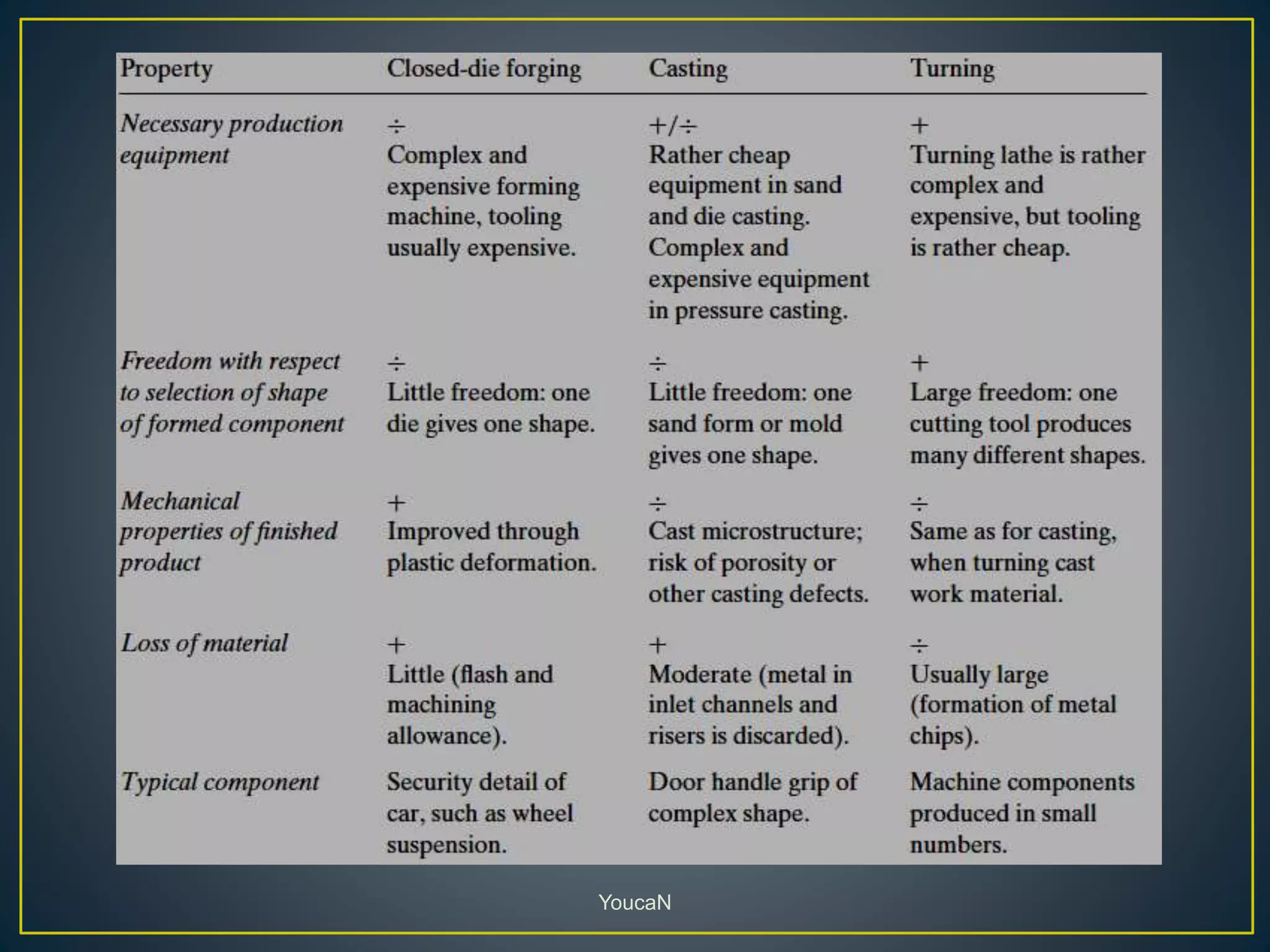

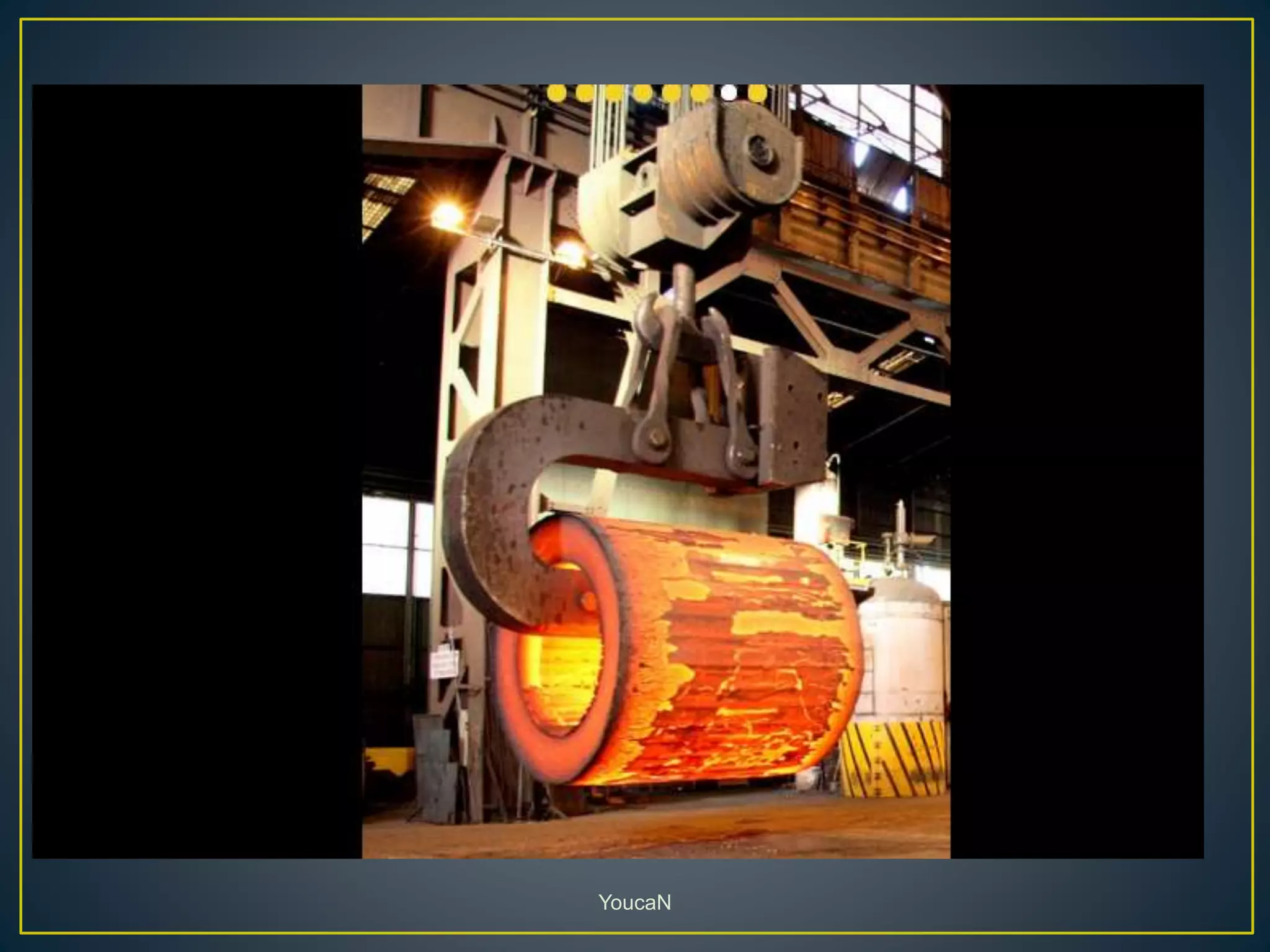

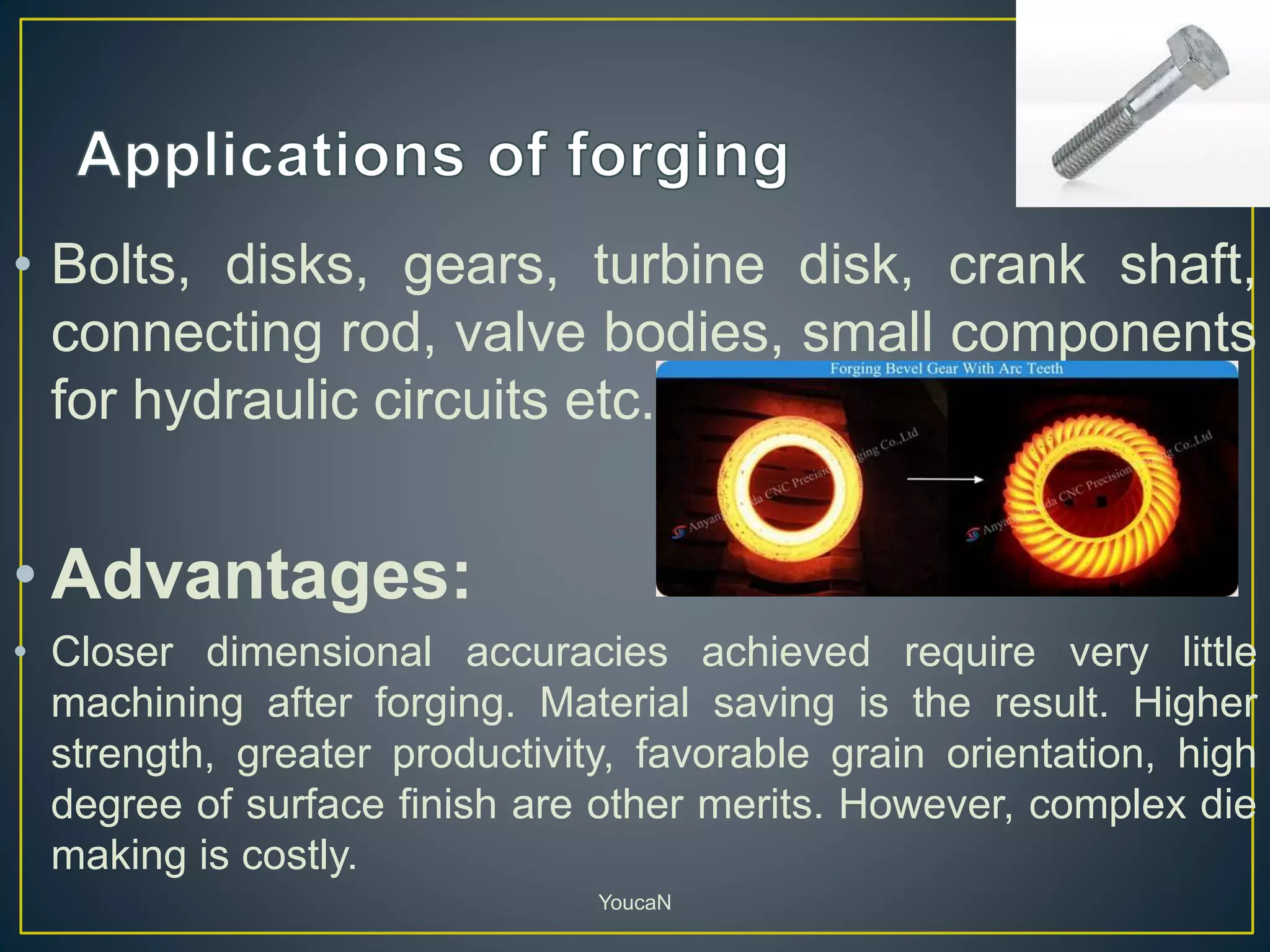

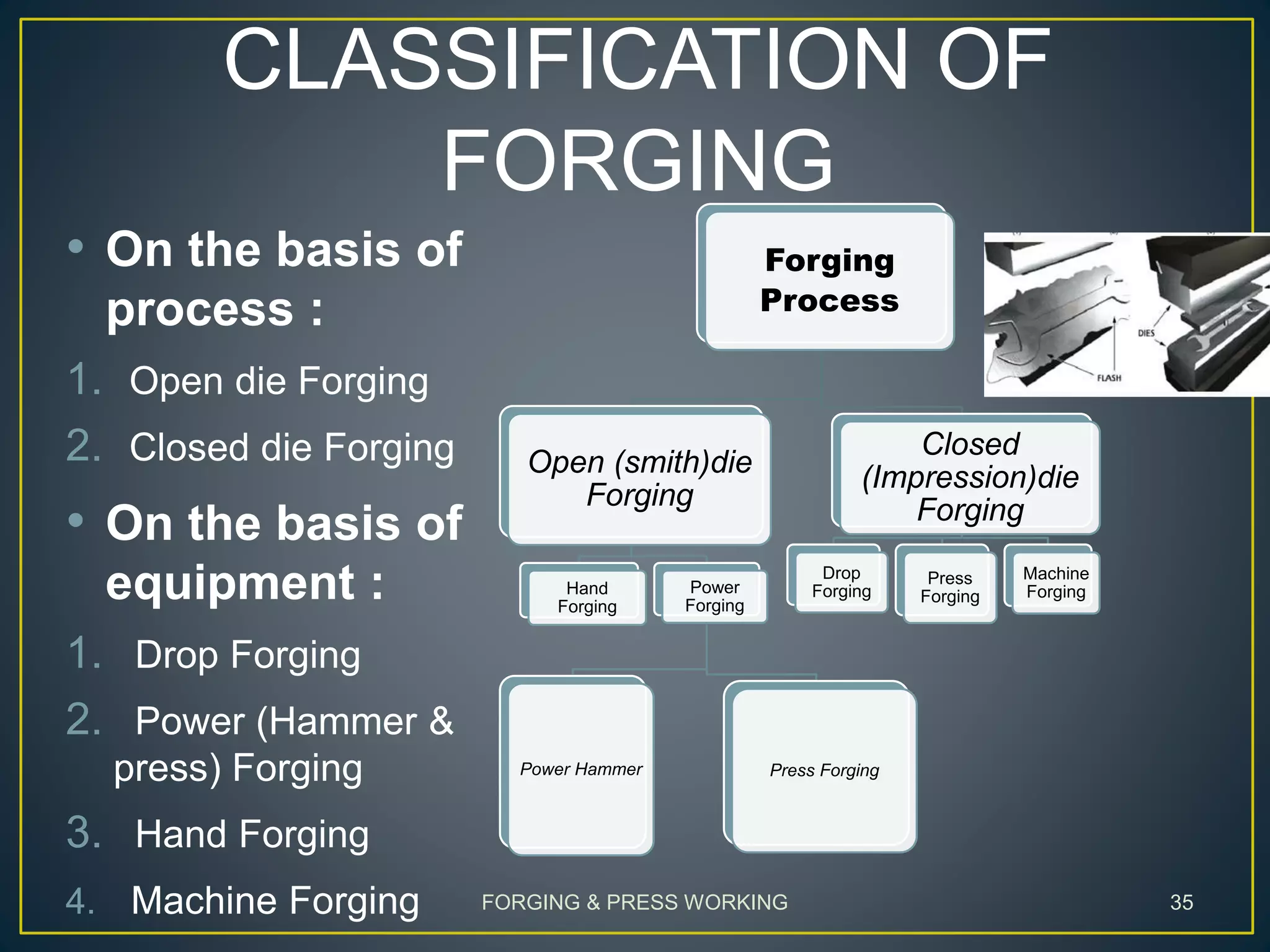

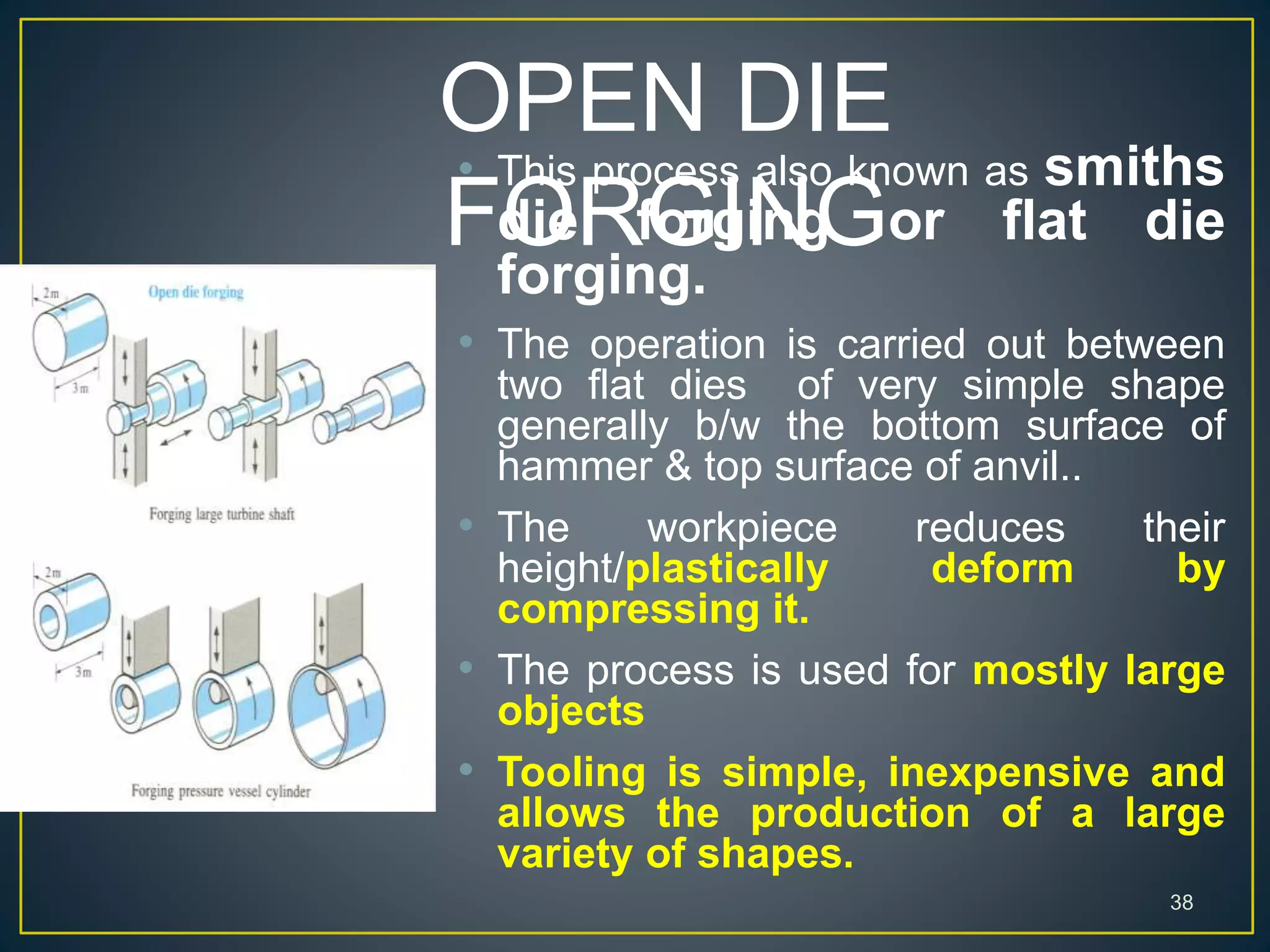

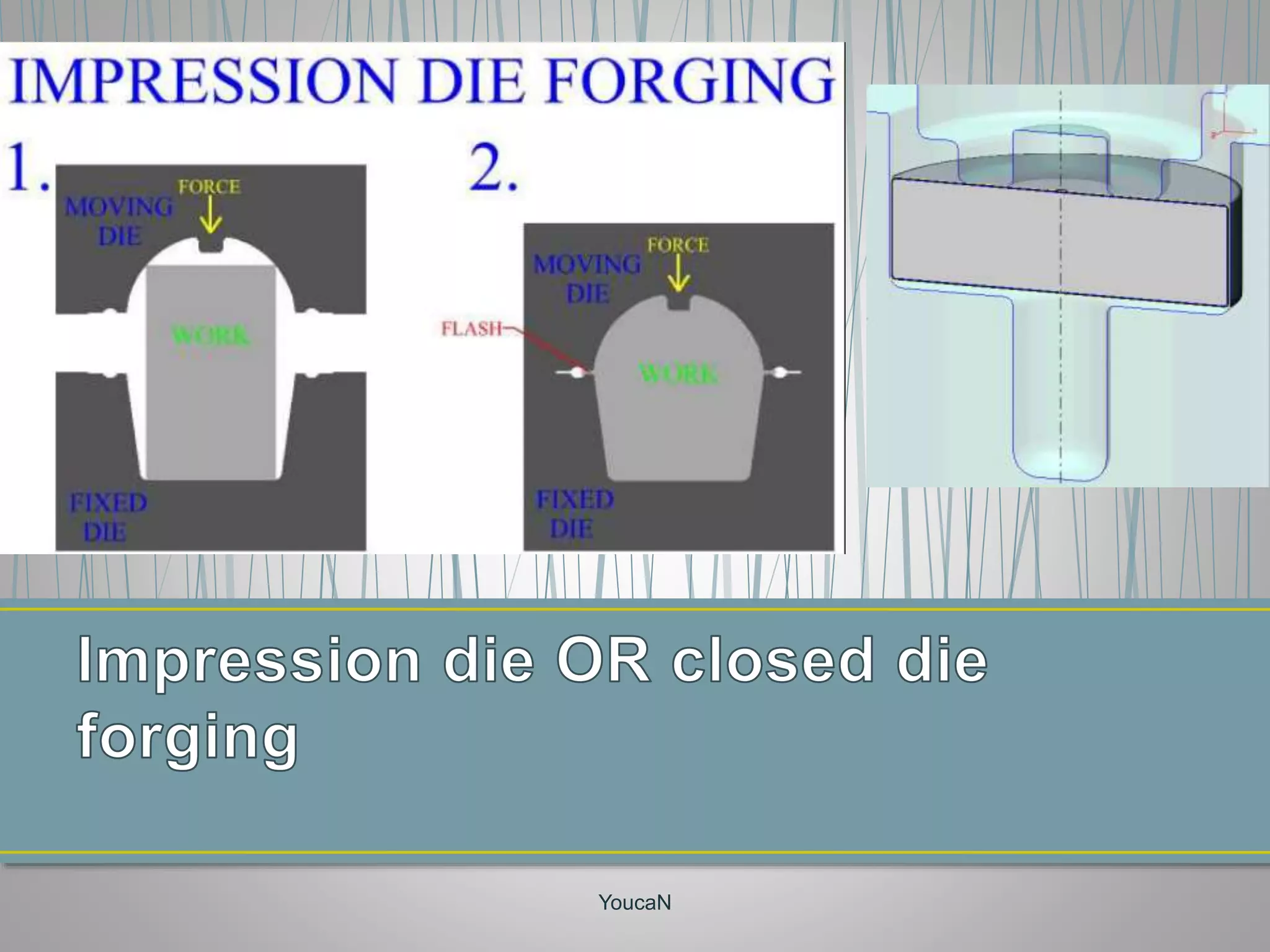

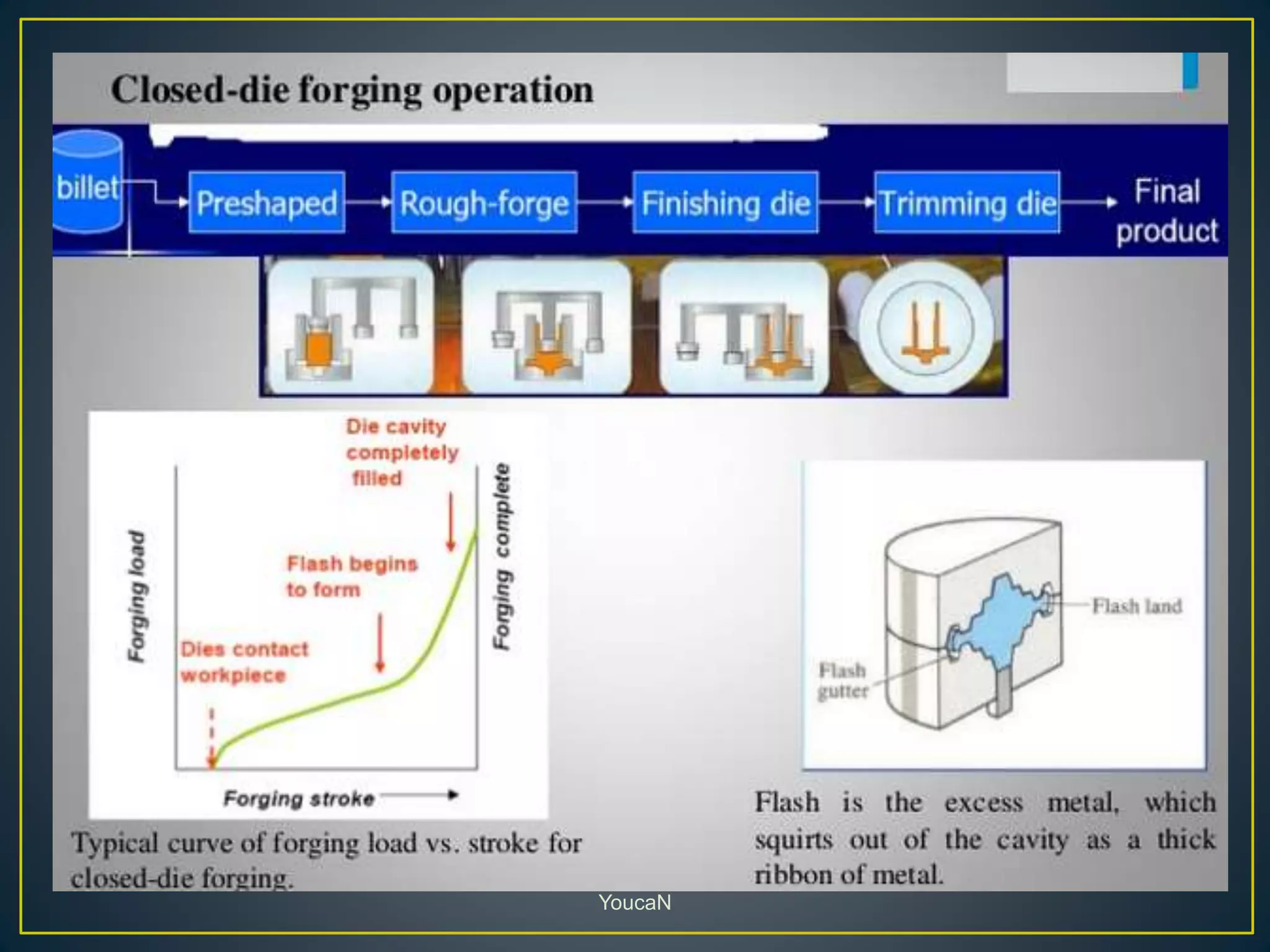

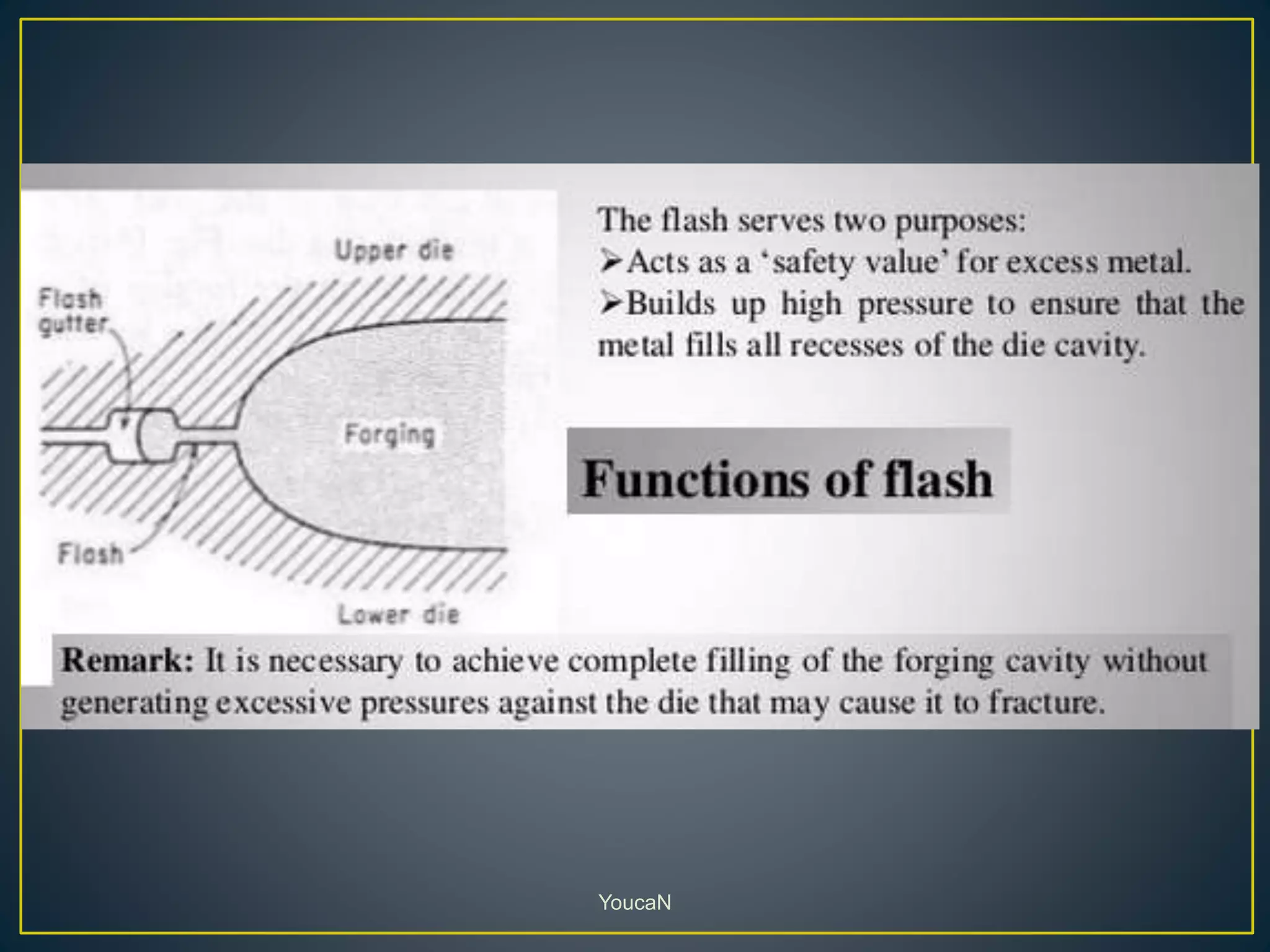

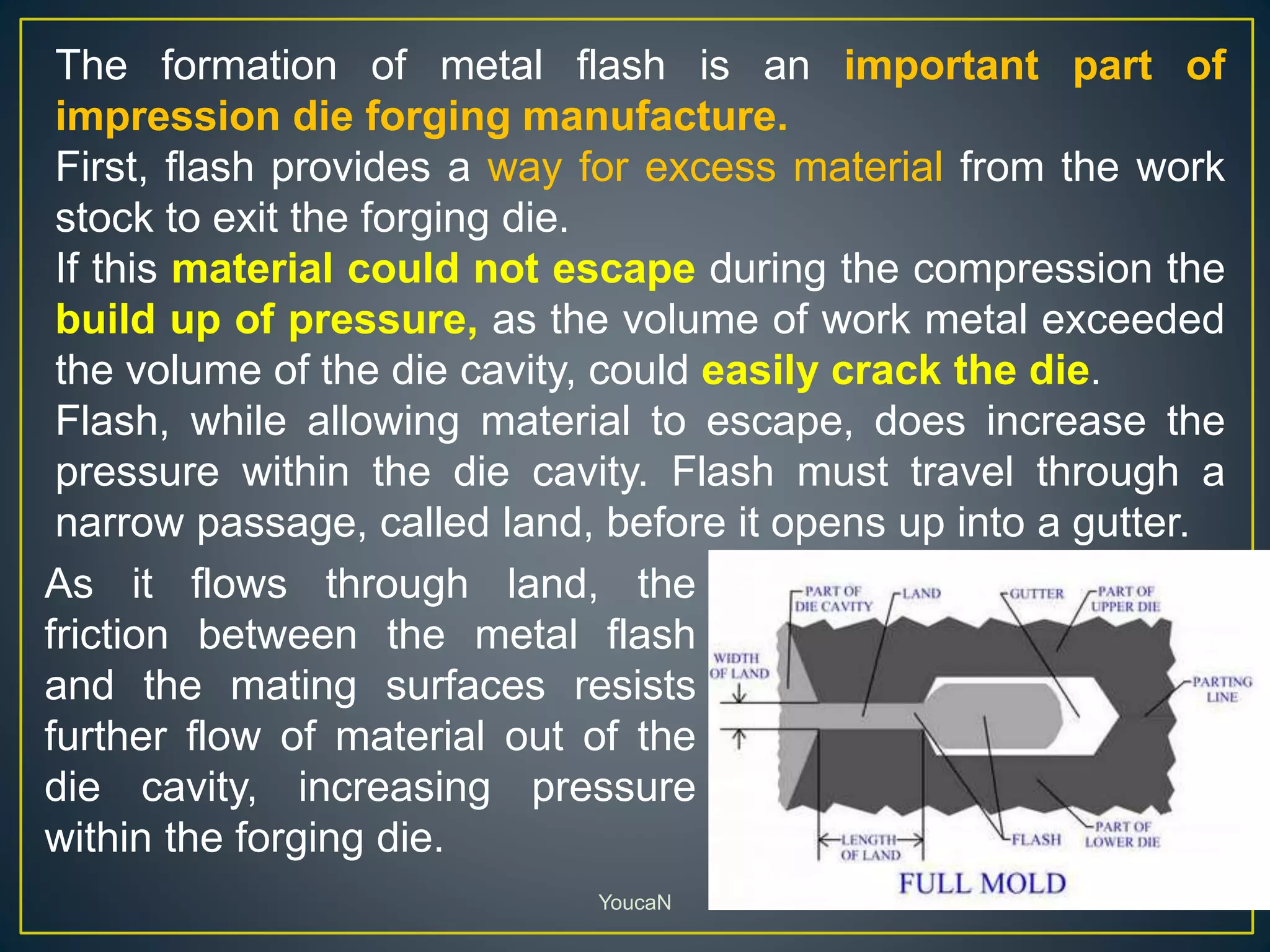

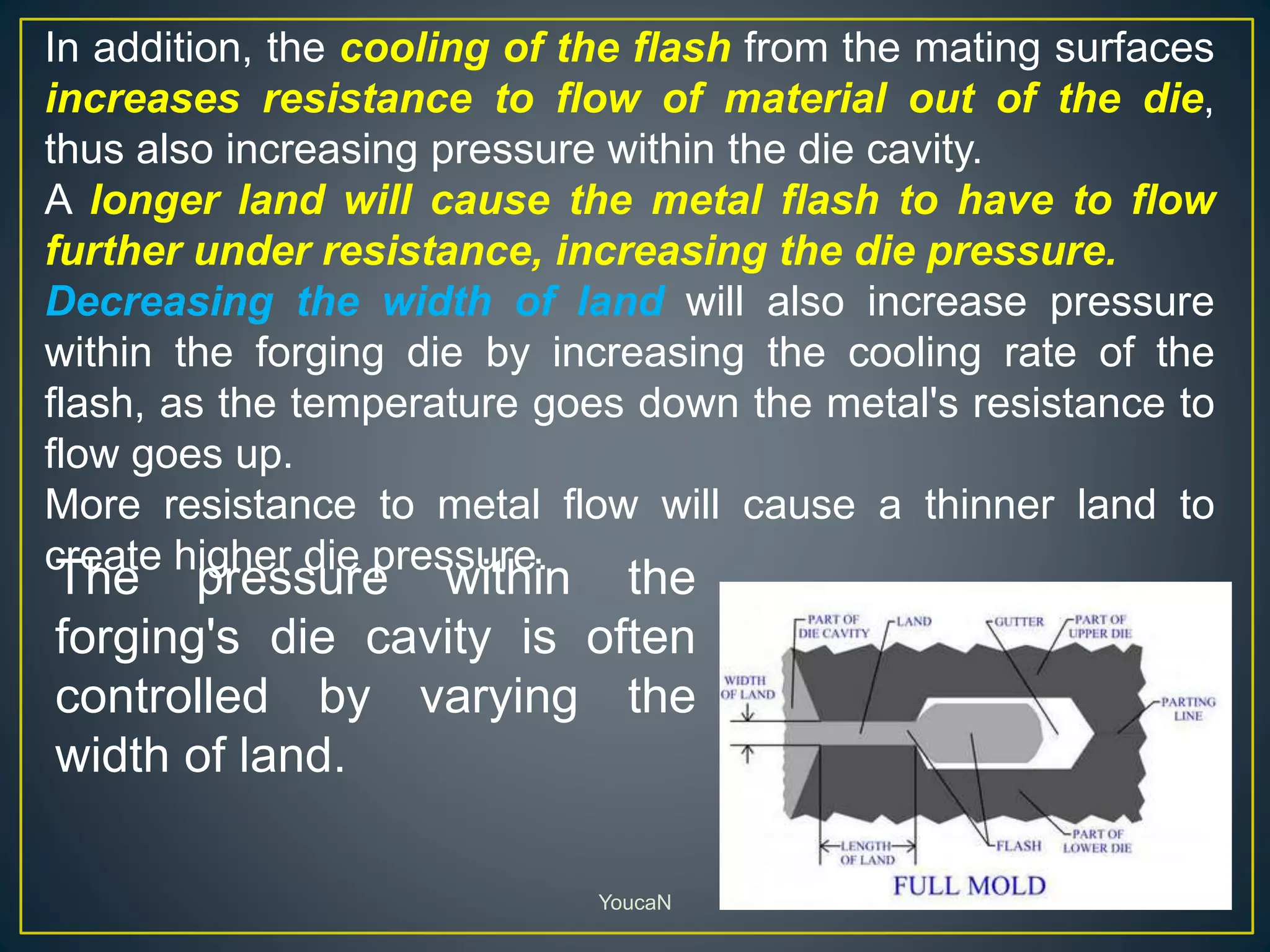

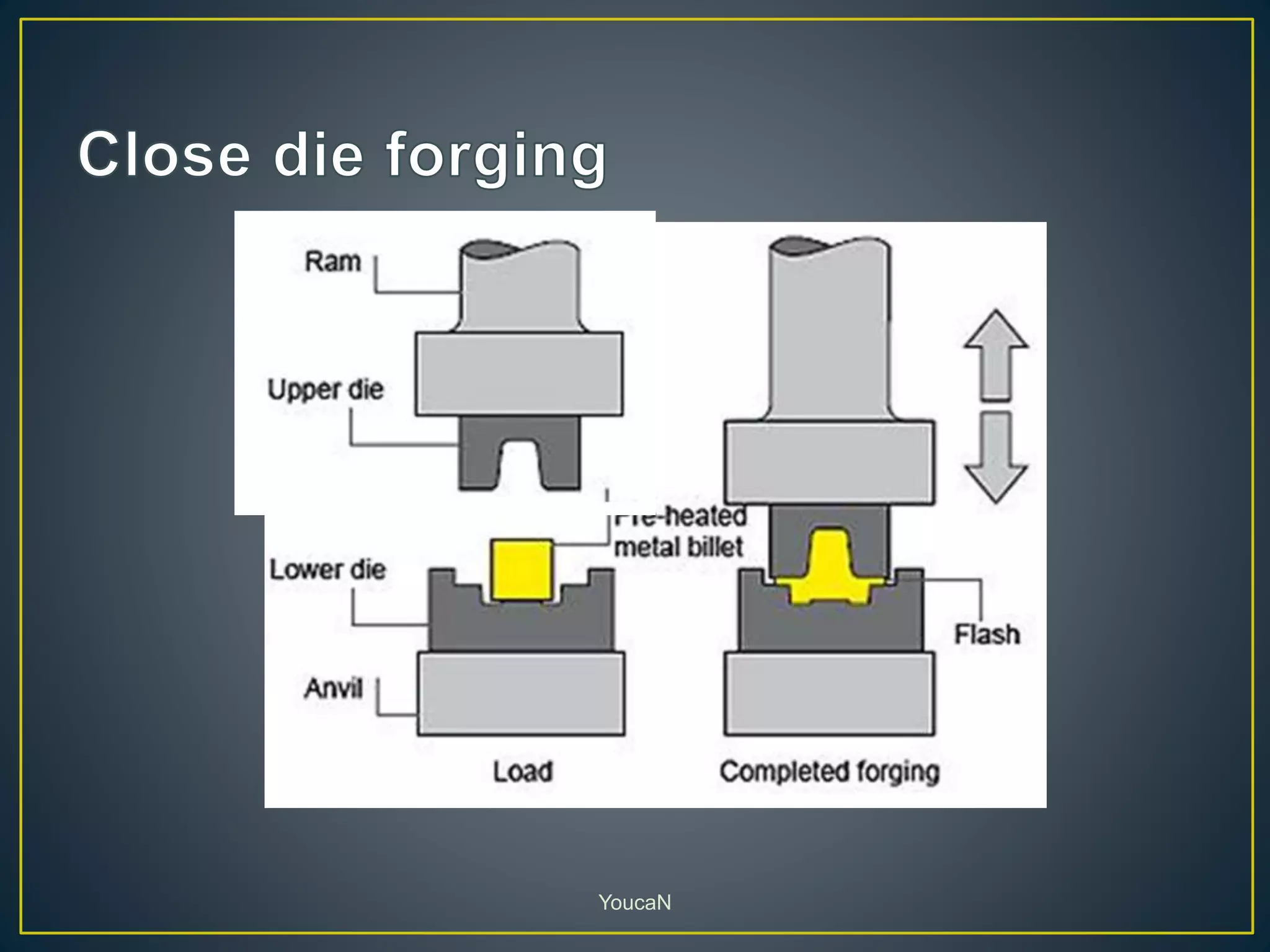

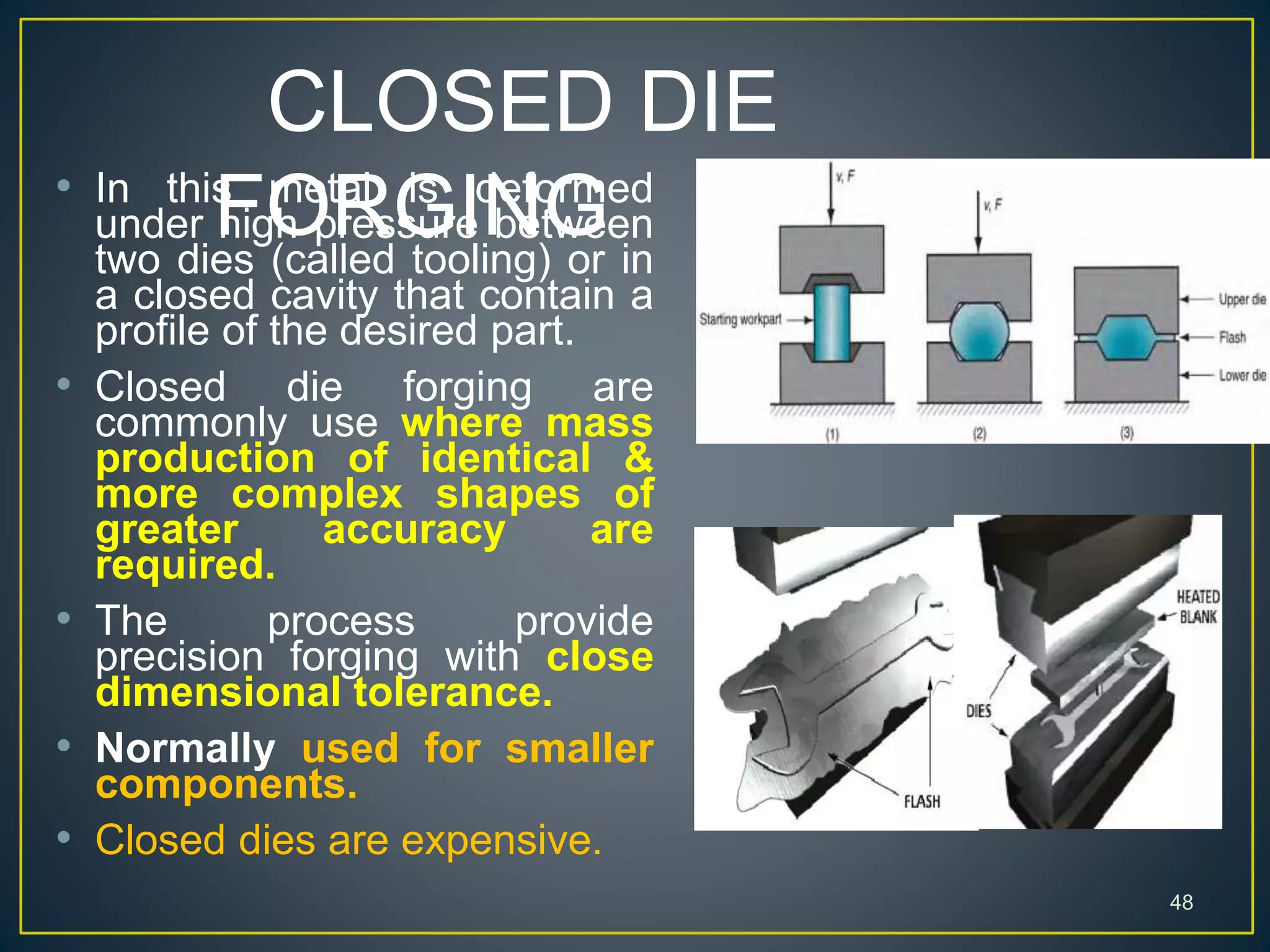

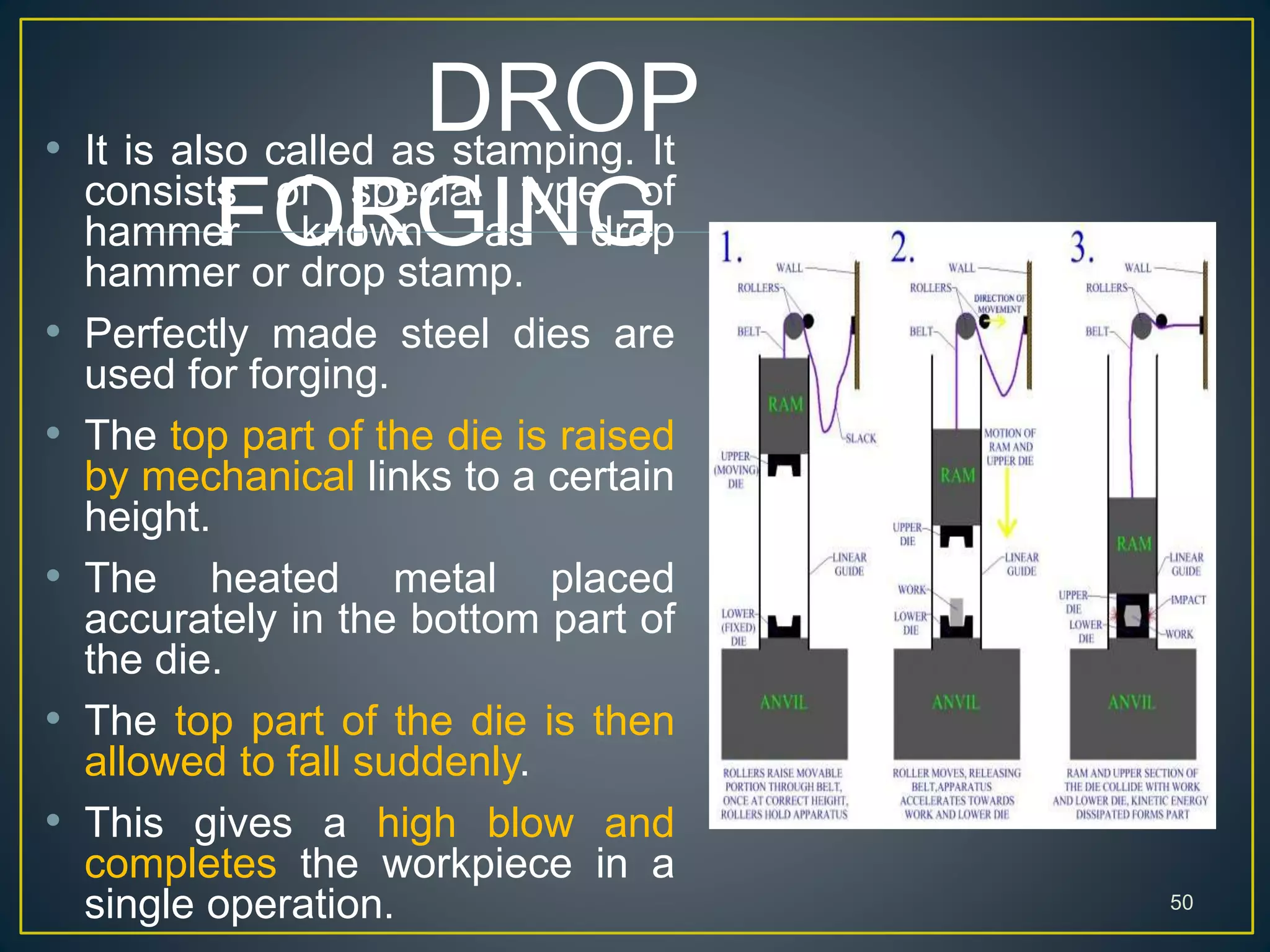

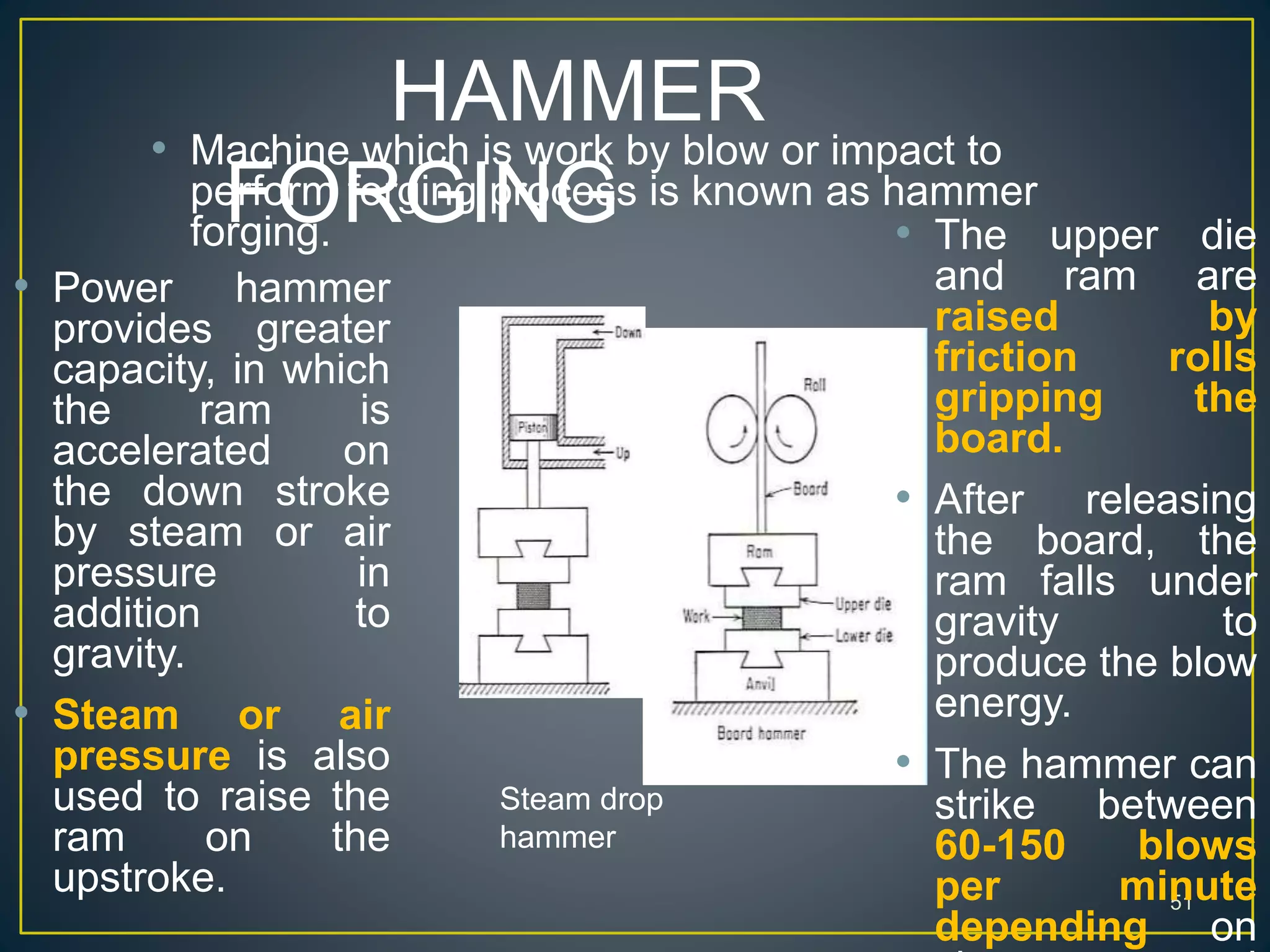

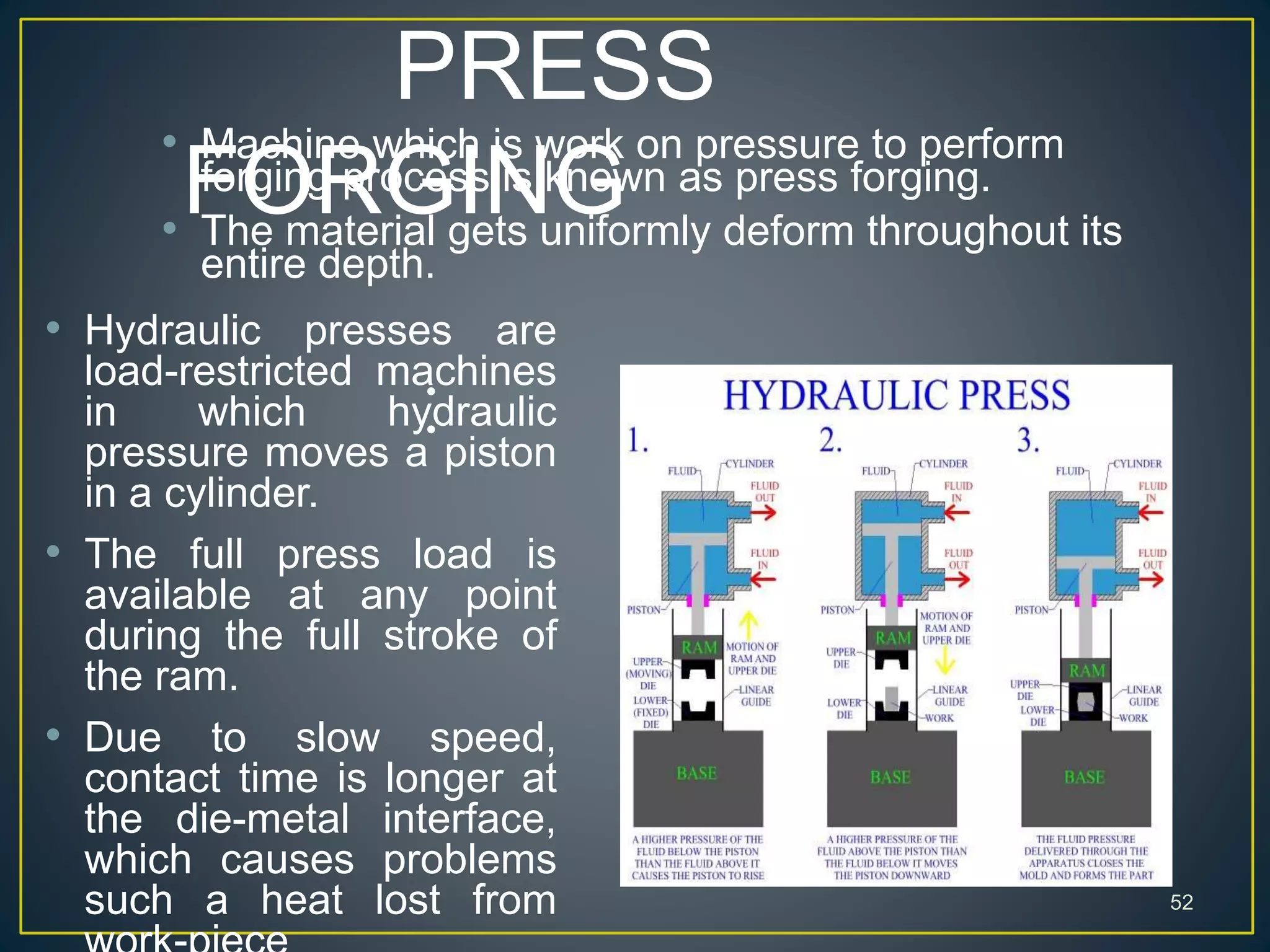

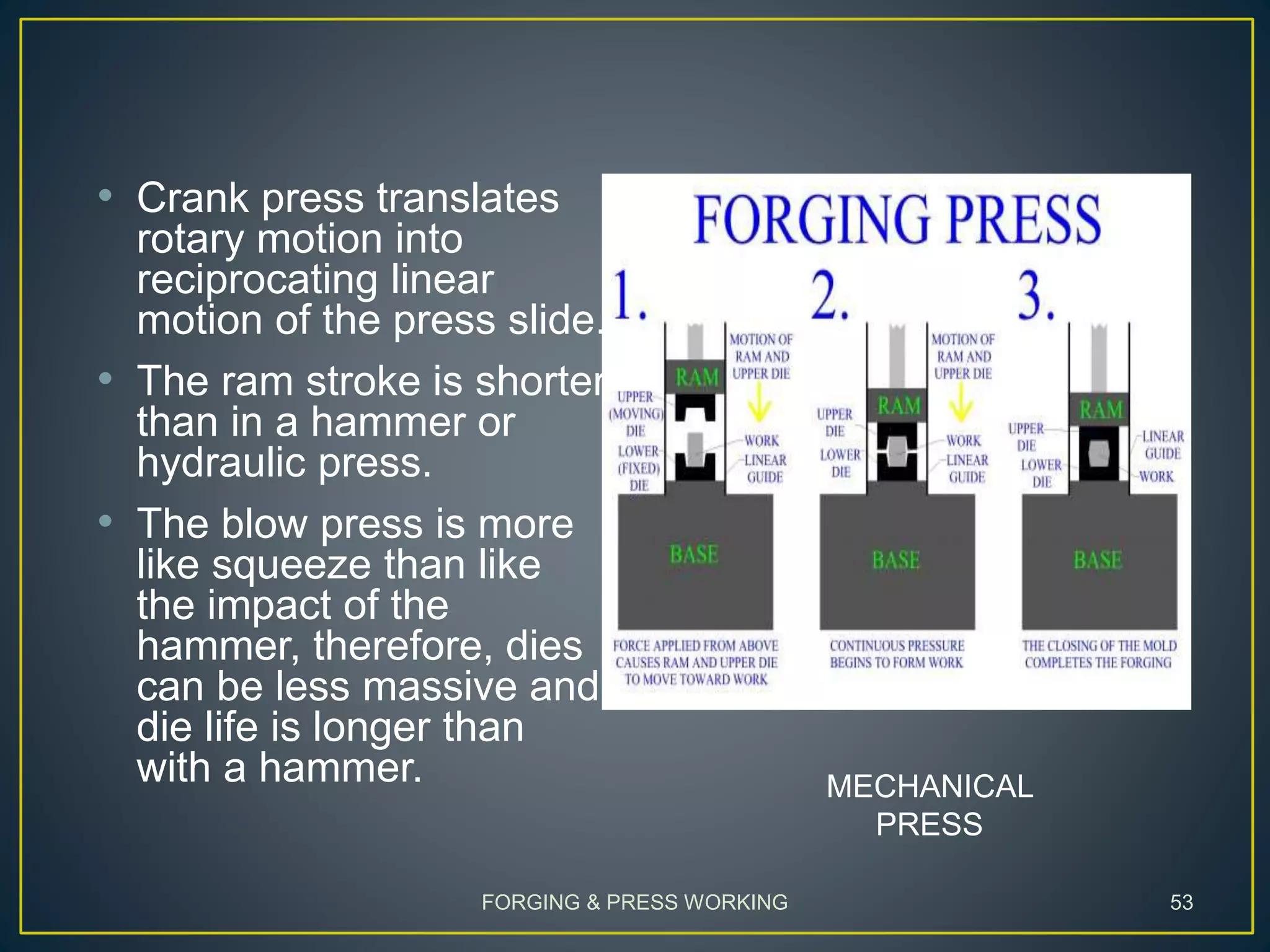

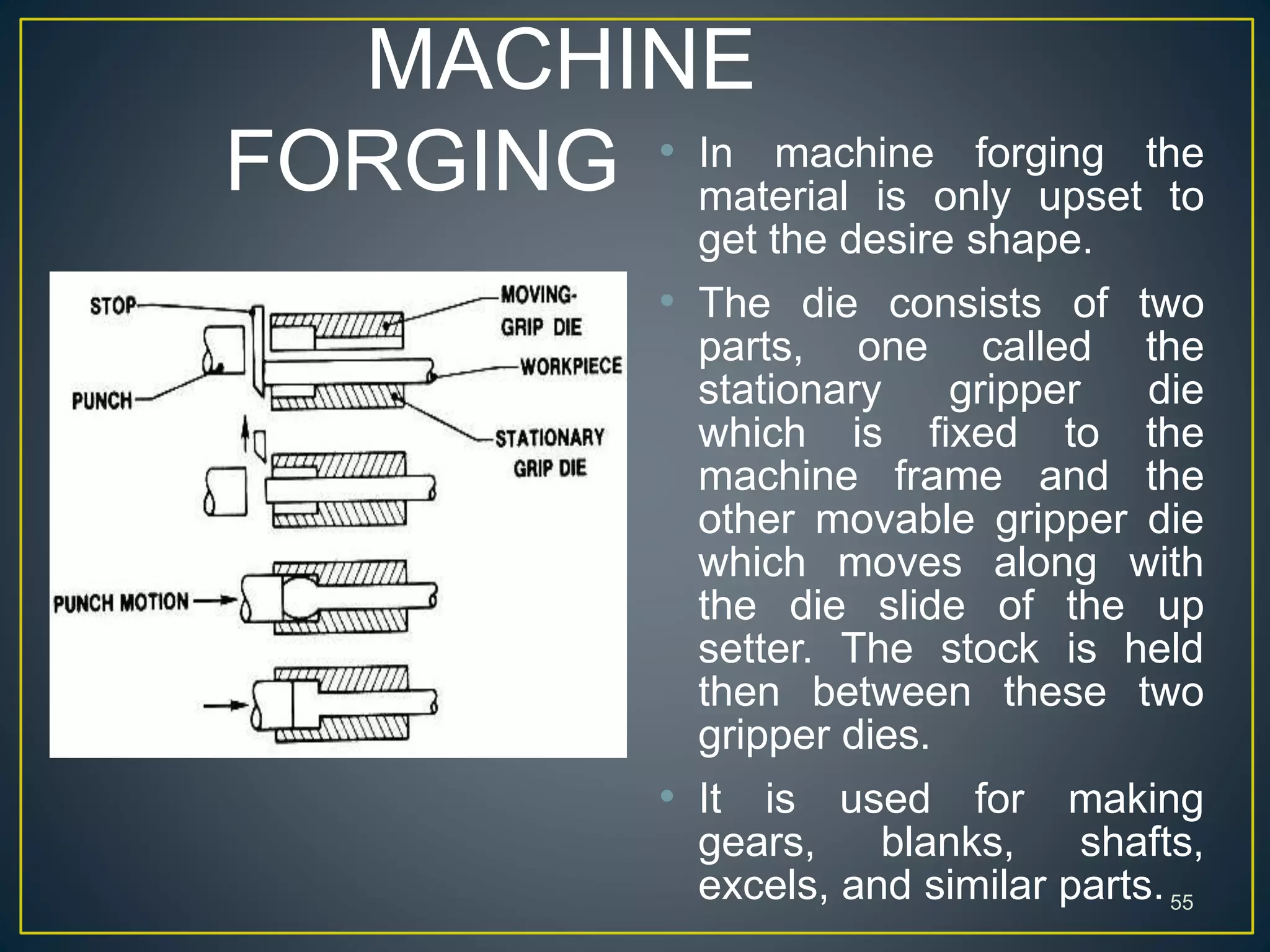

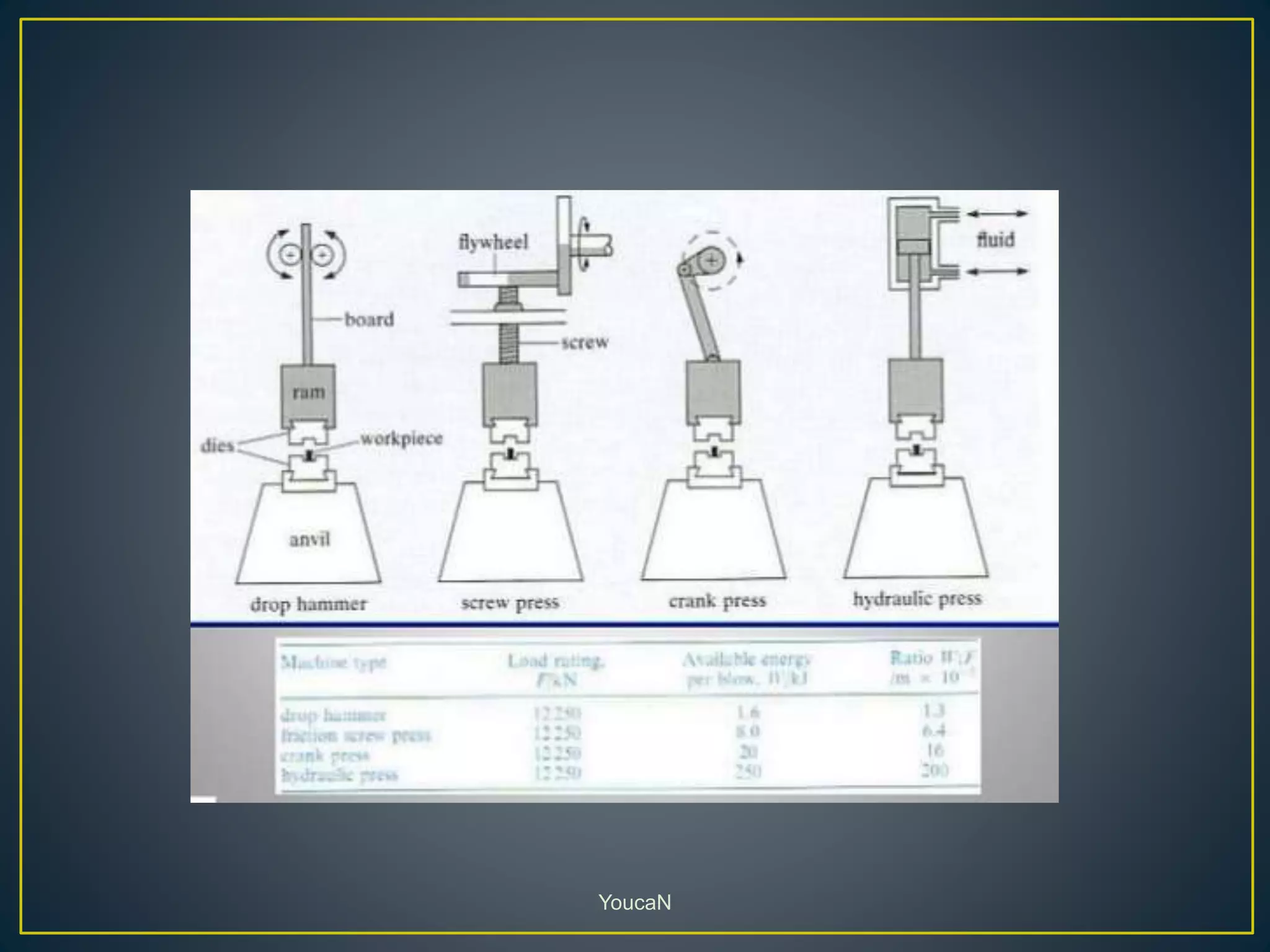

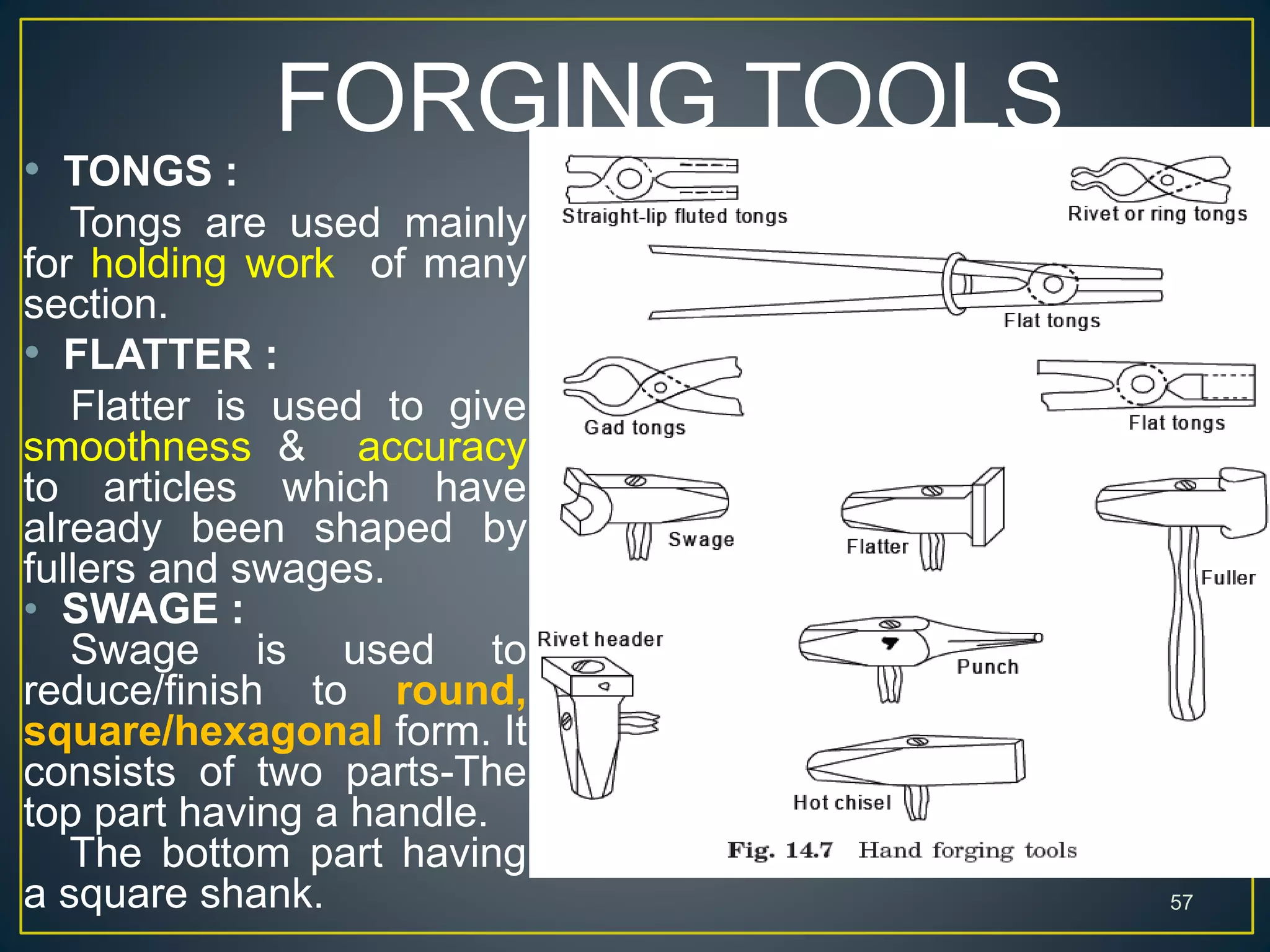

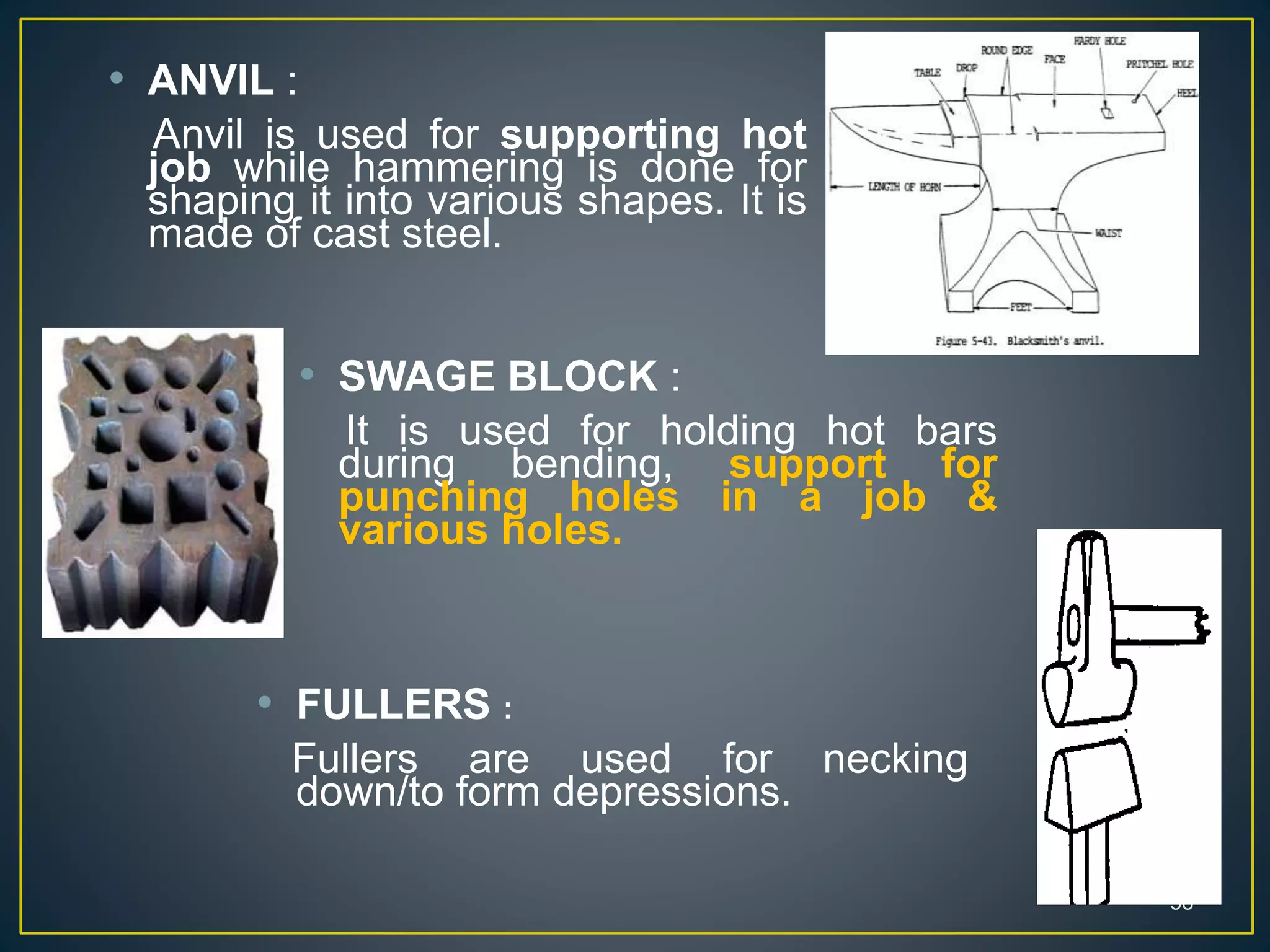

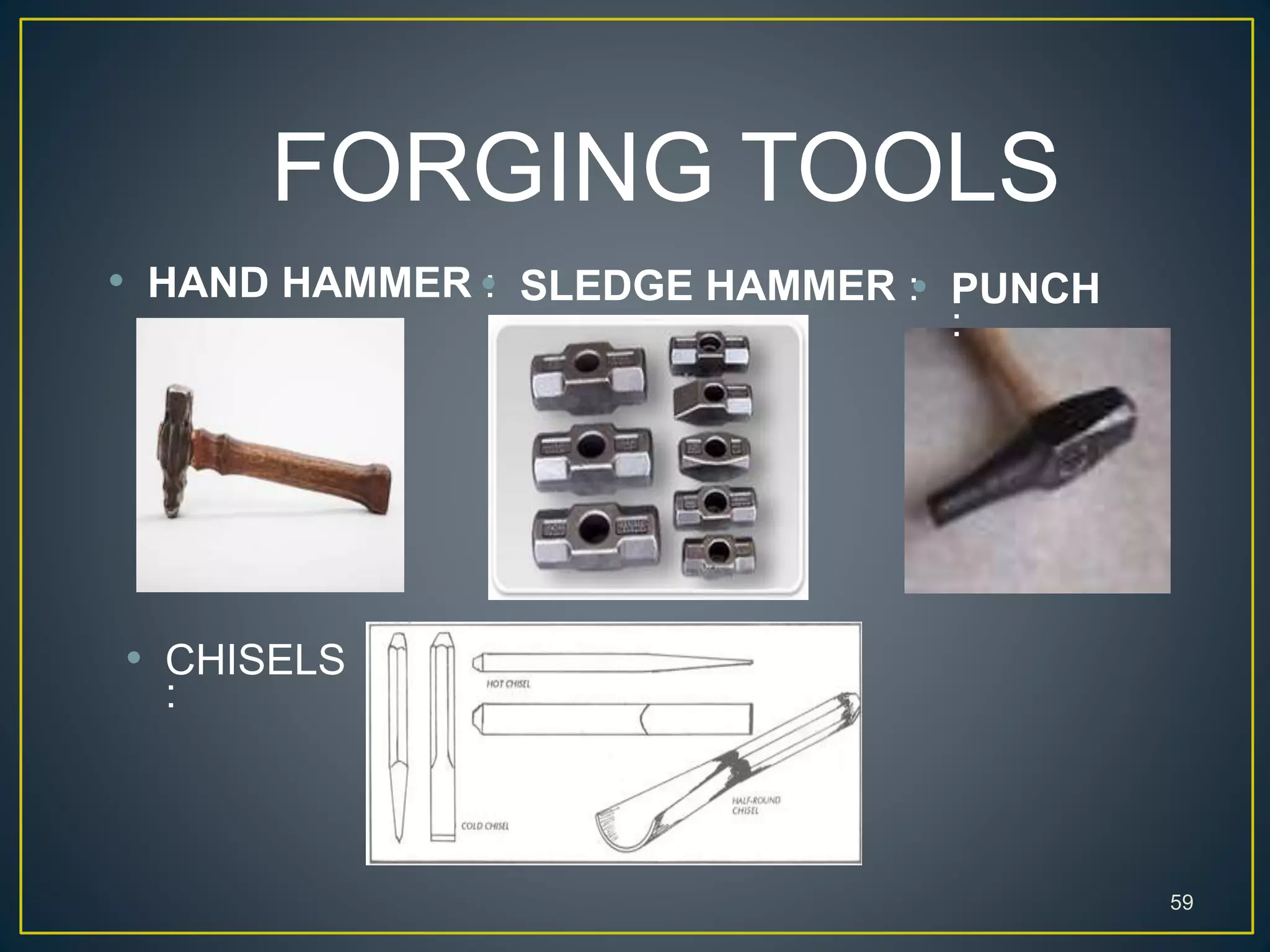

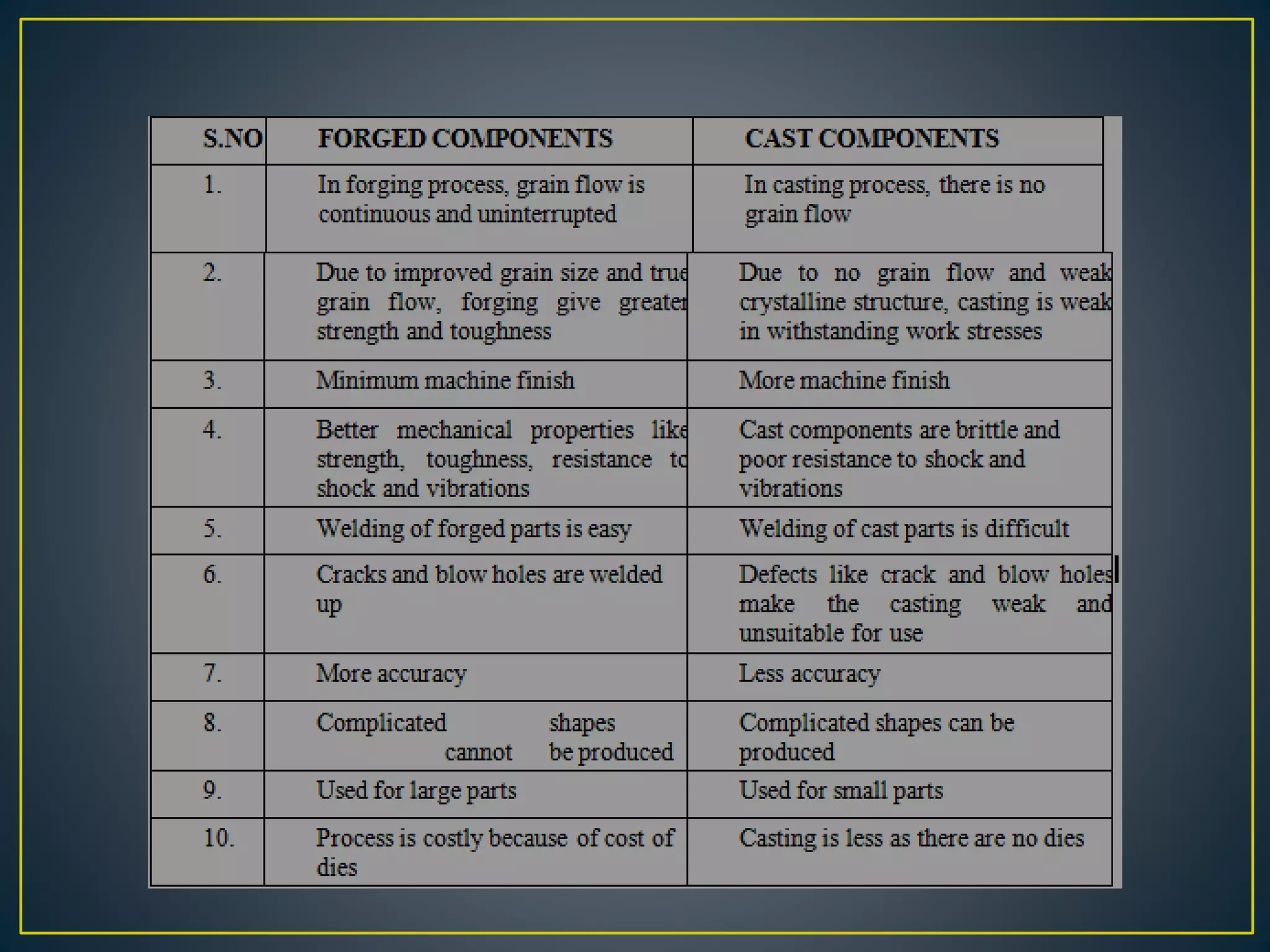

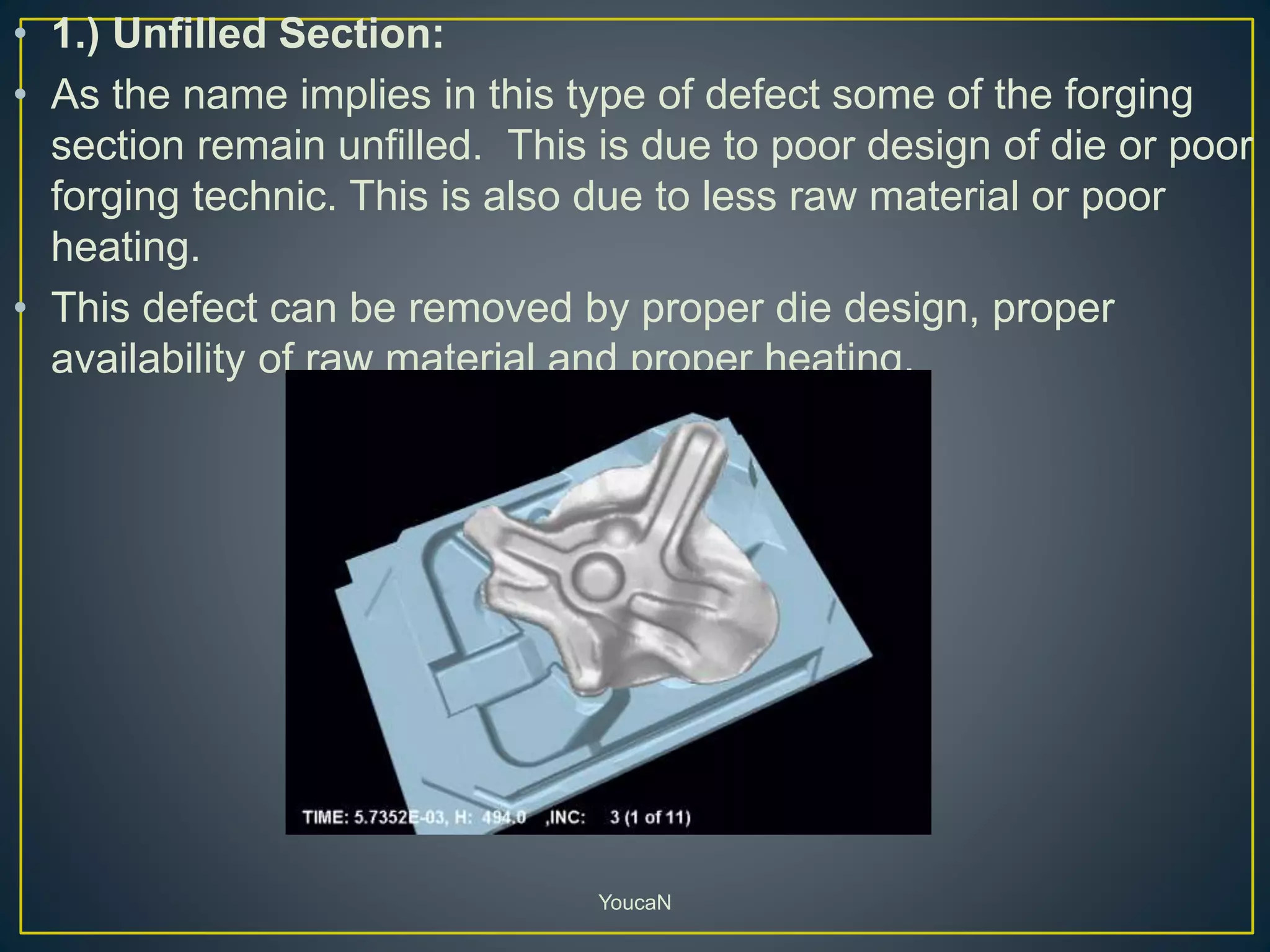

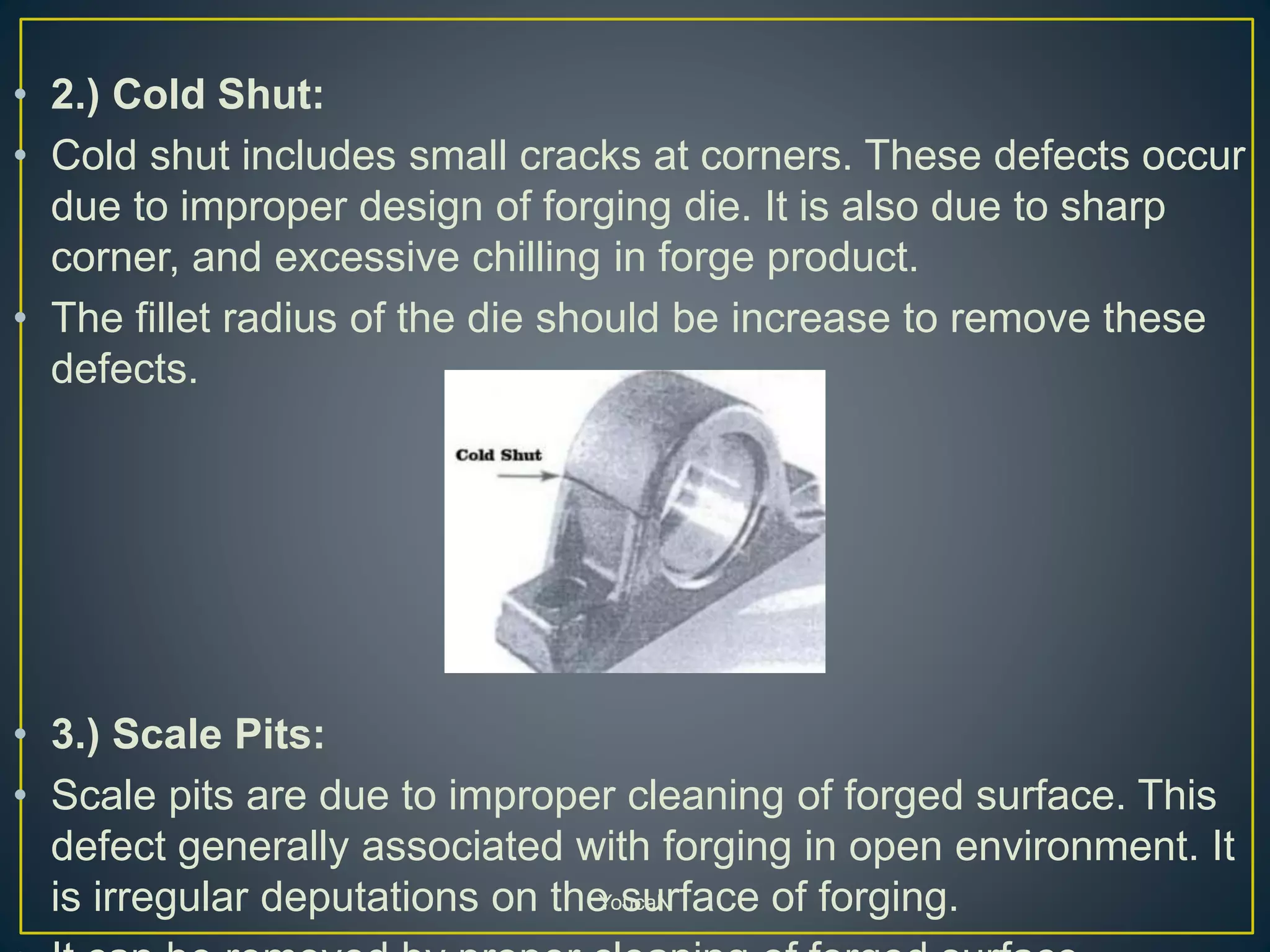

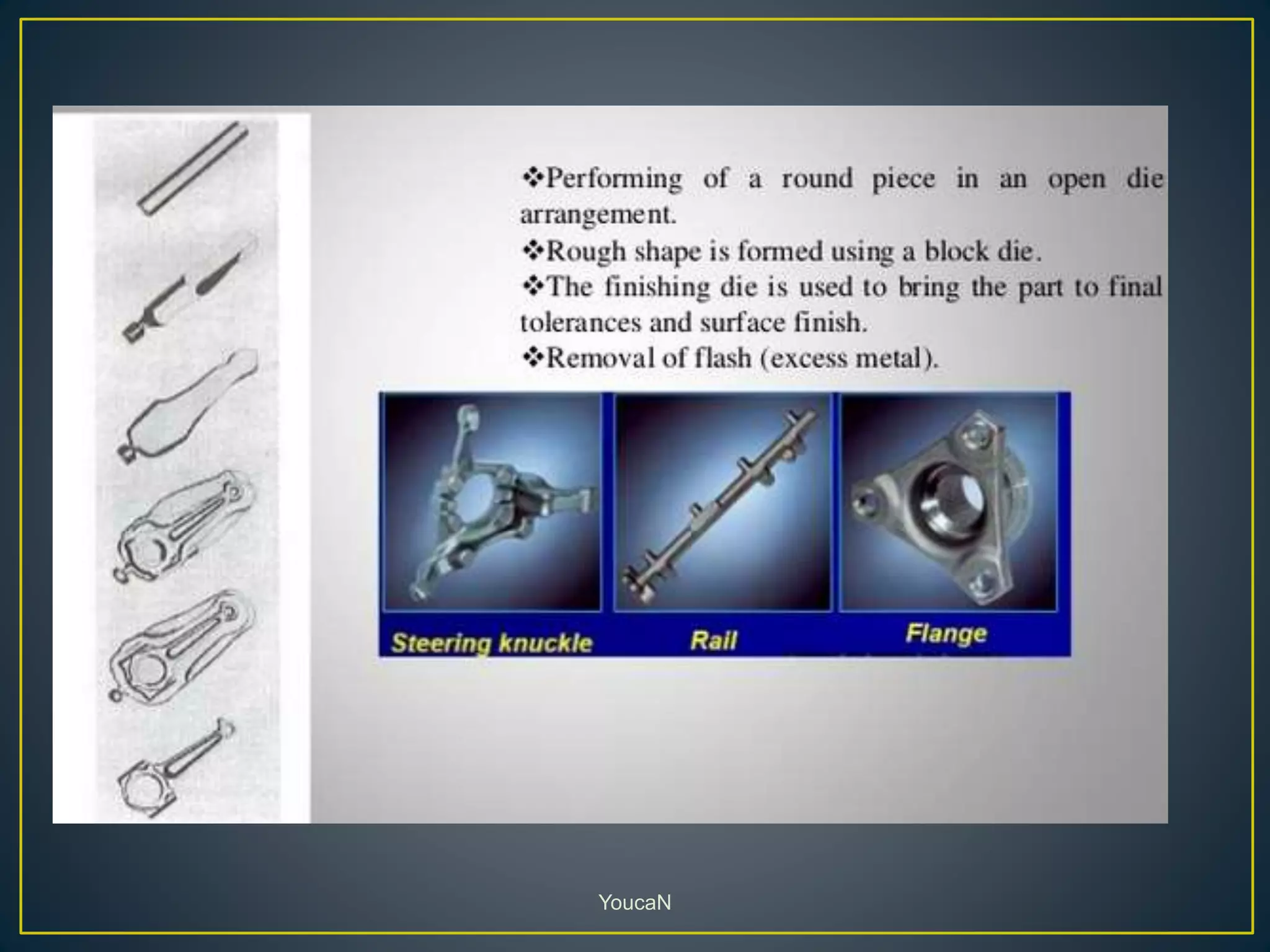

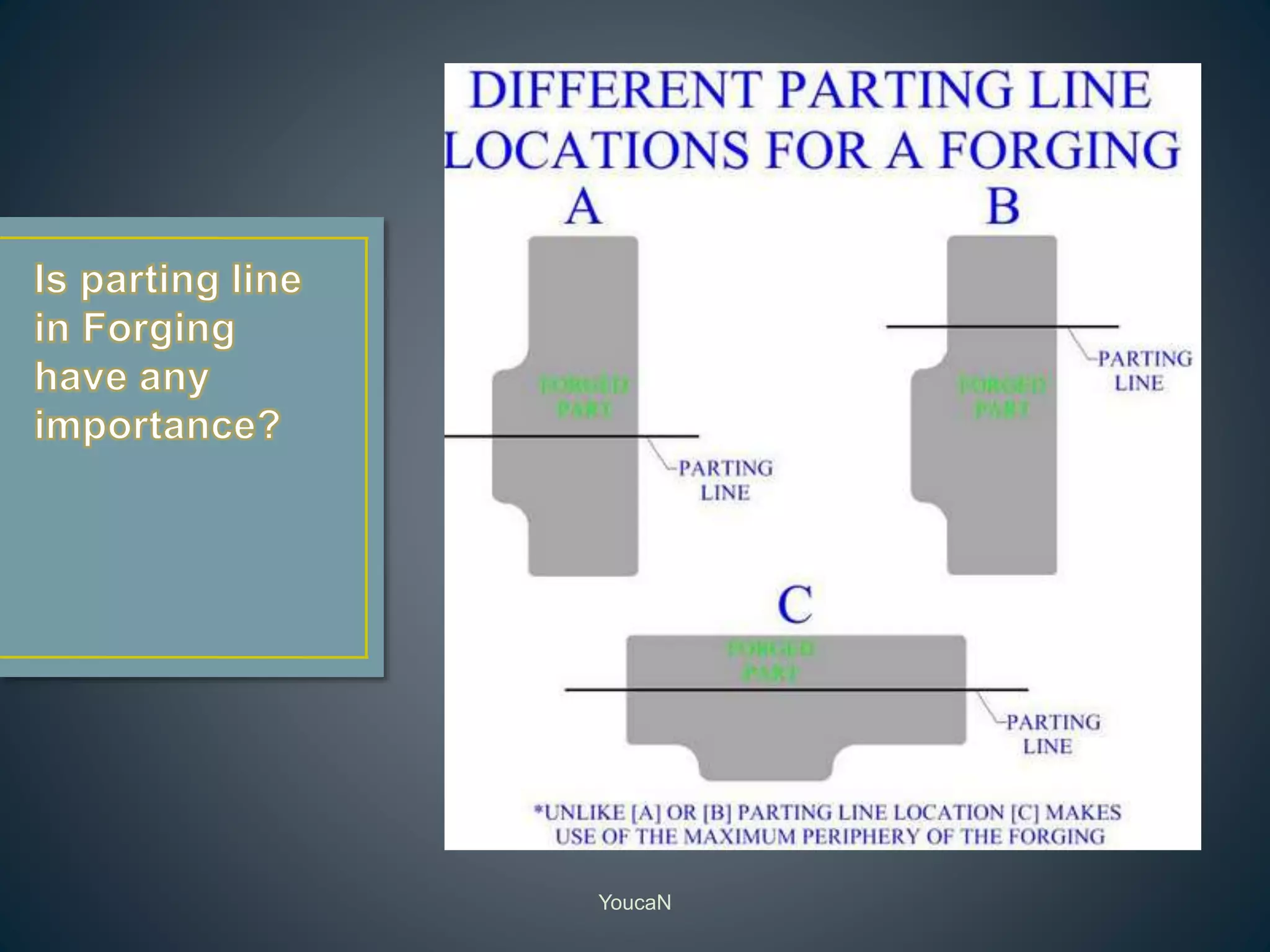

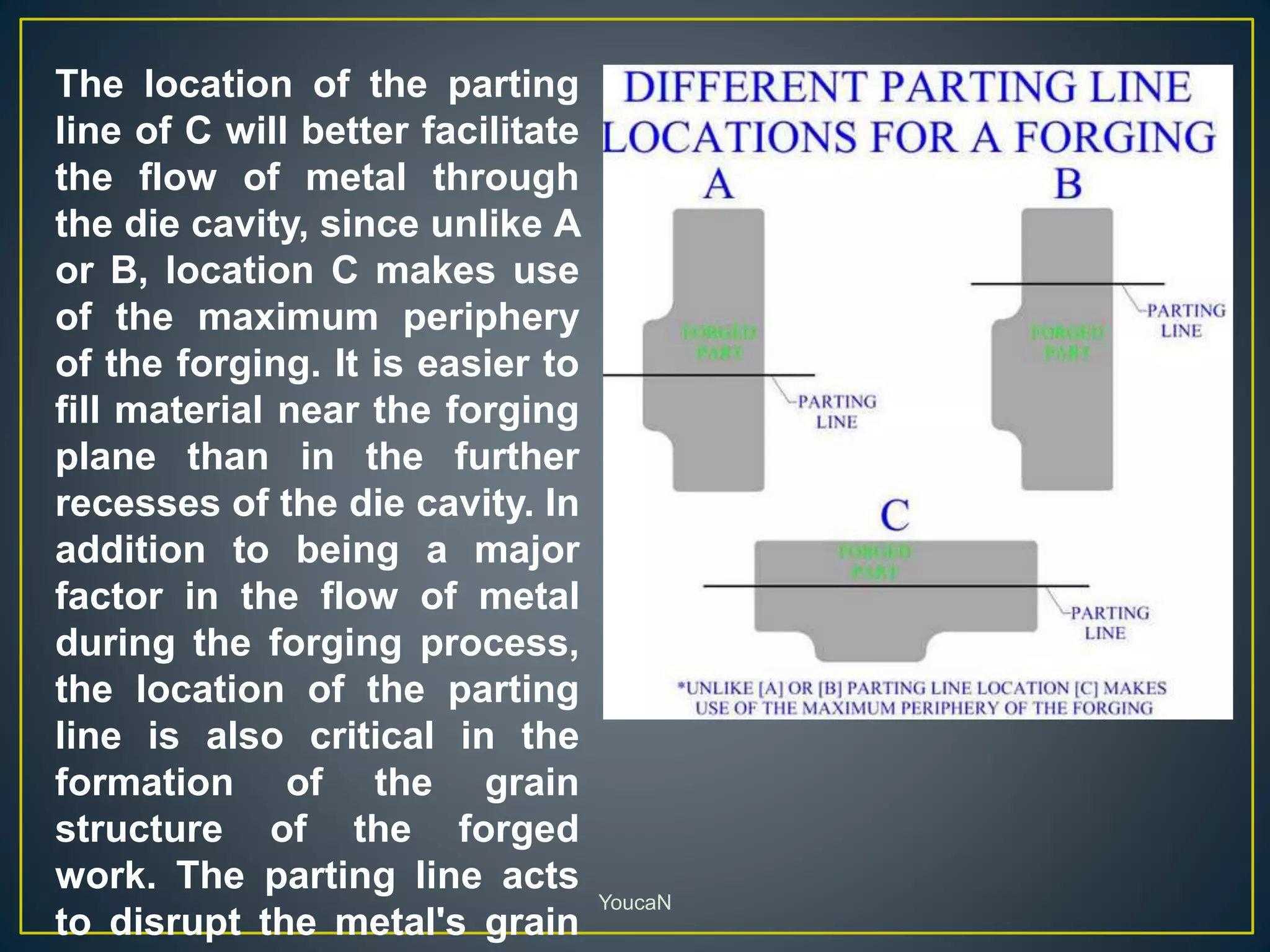

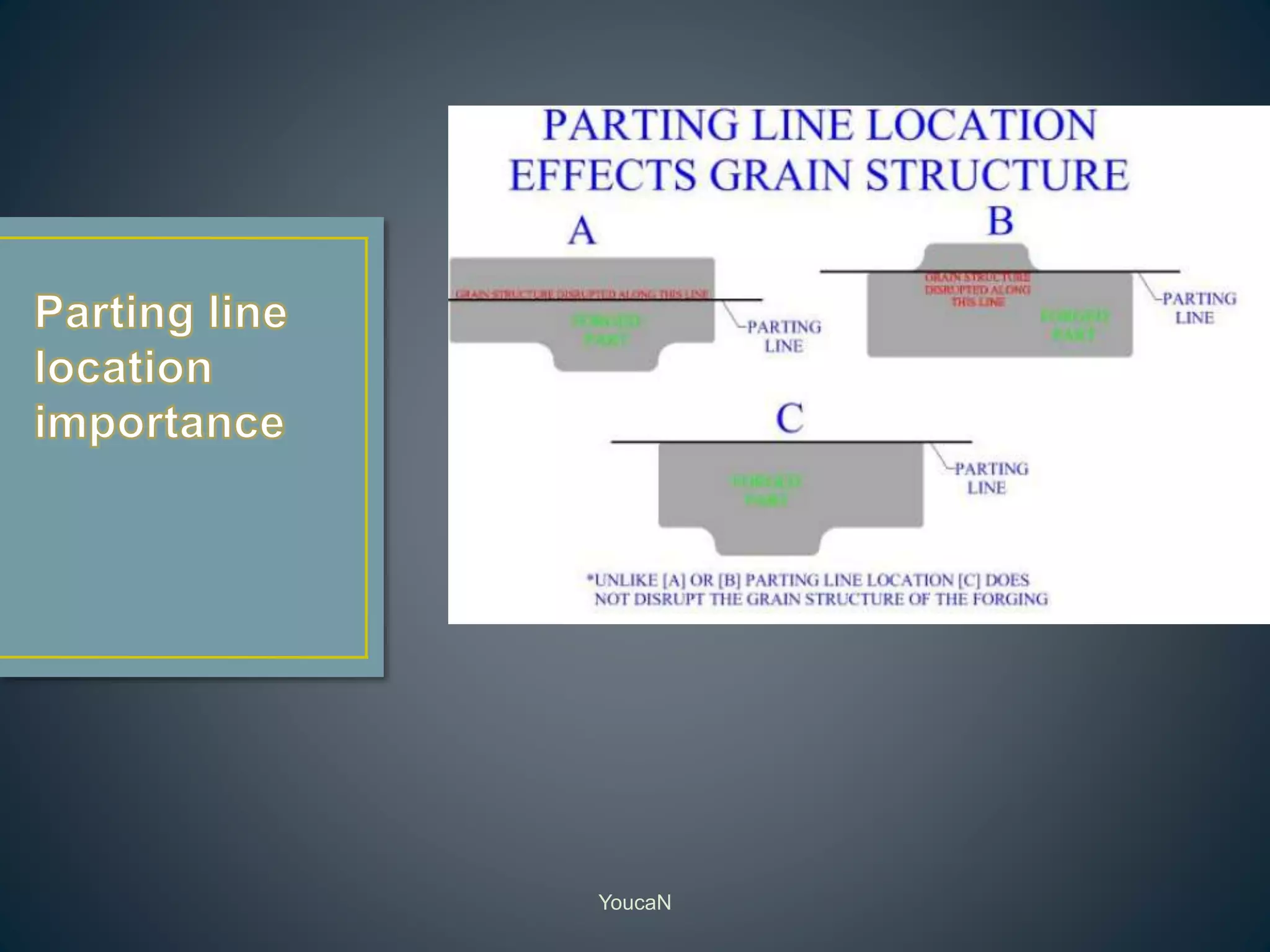

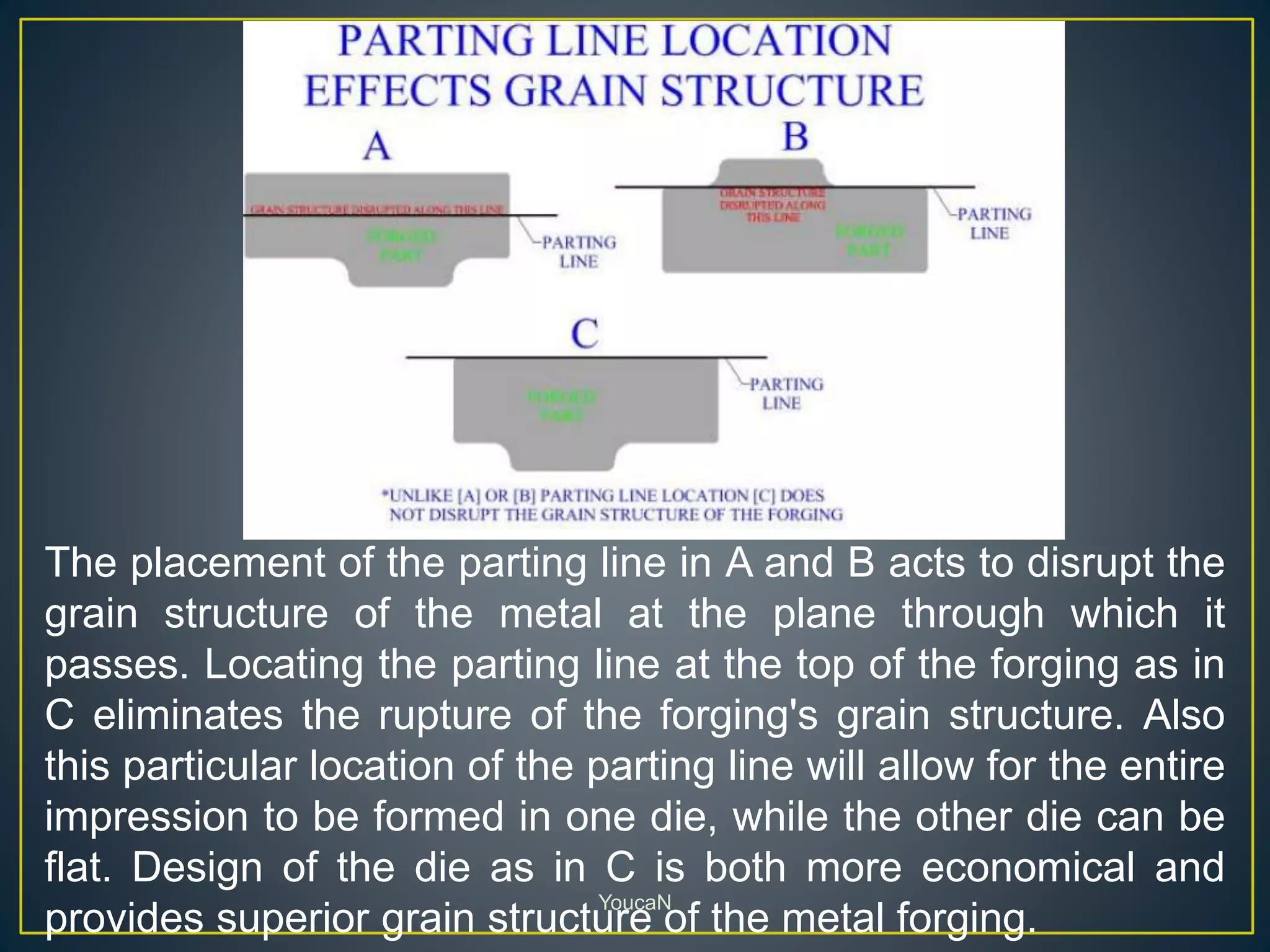

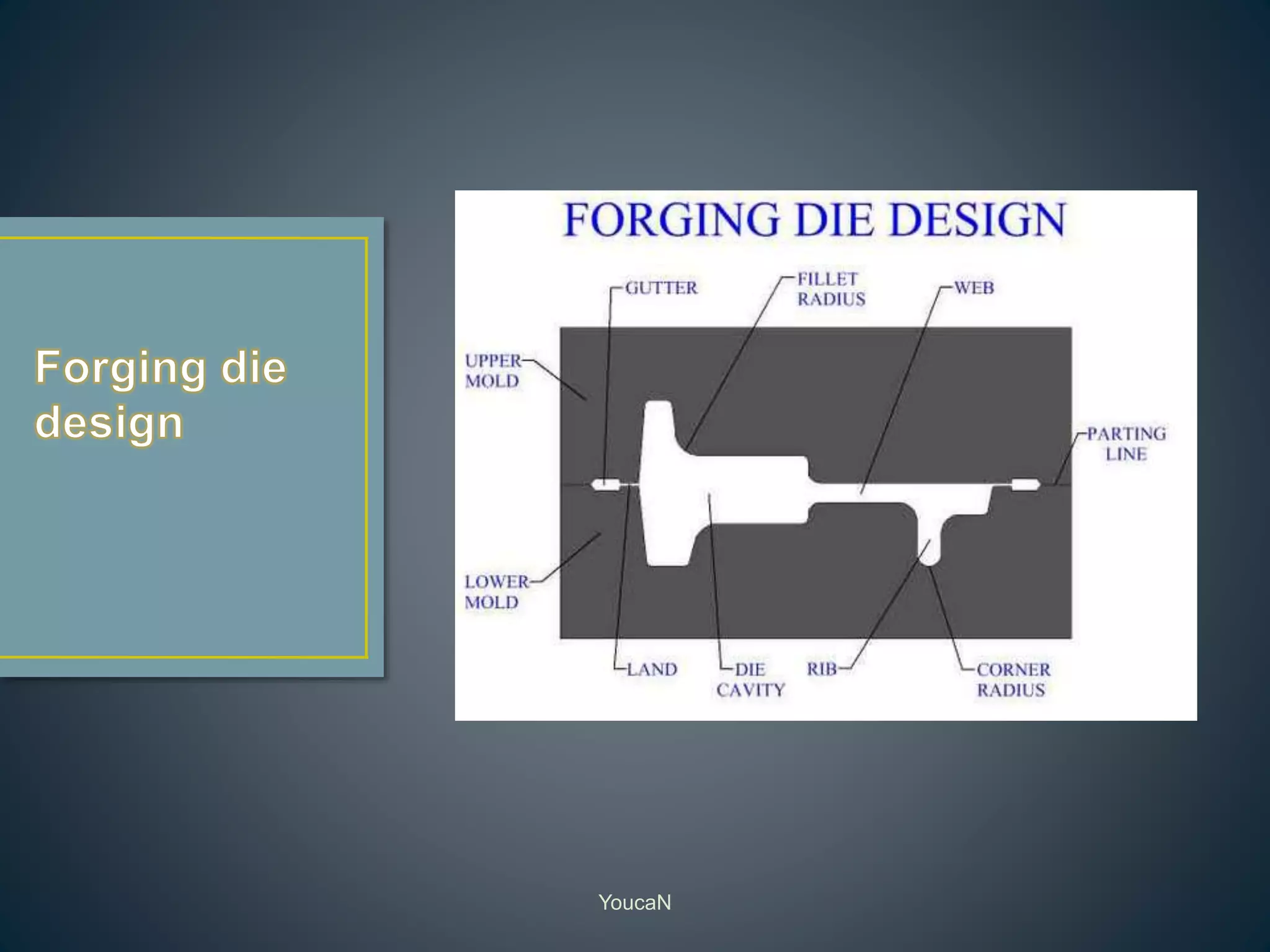

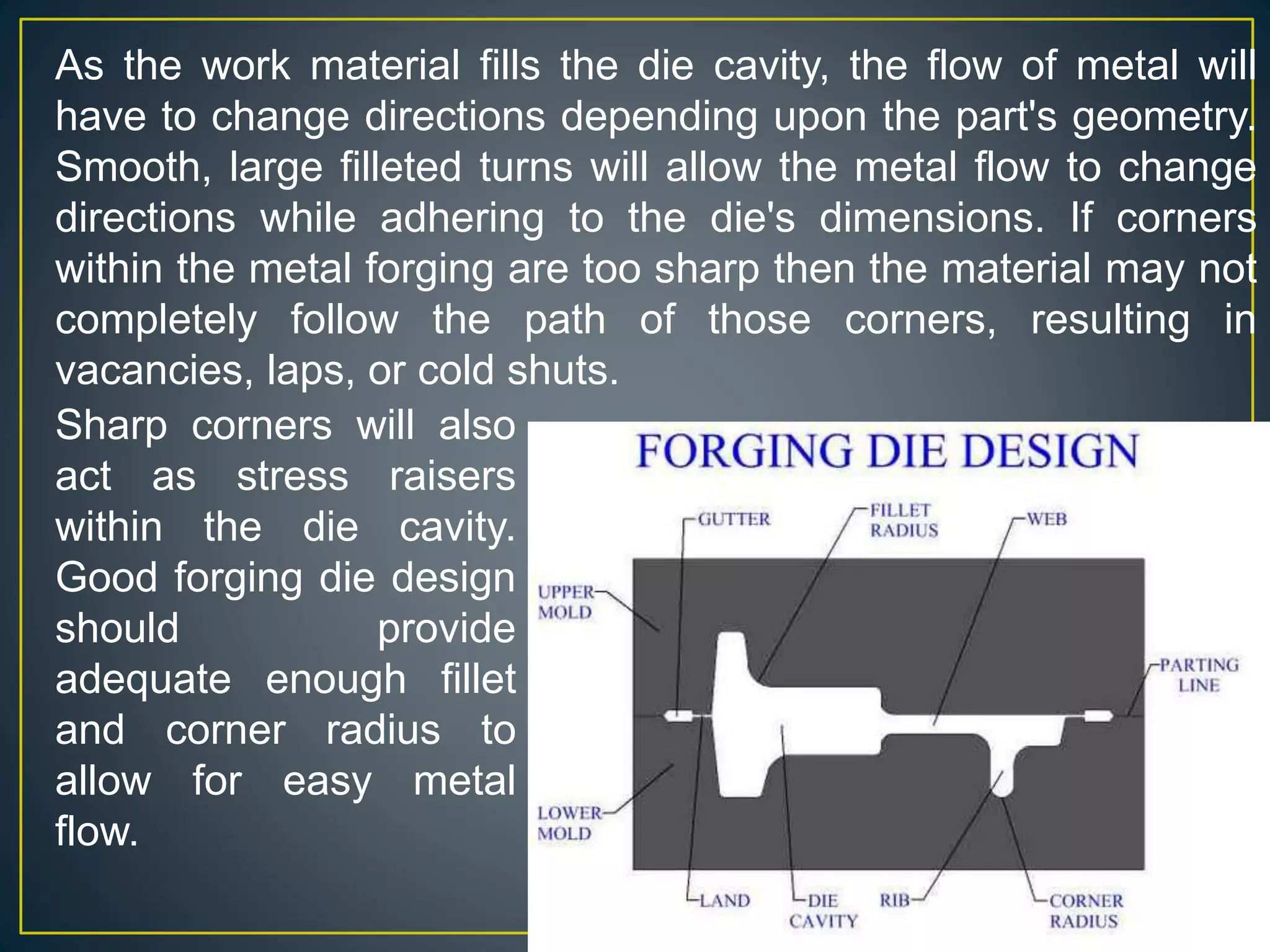

The document discusses various metal forming processes including forging processes like open die, closed die, and impression forging. It describes types of rolling processes and defects in rolled parts. It also covers principles of extrusion, types of extrusion, and tube drawing. Different metal forming techniques like forging, rolling, and extrusion are discussed along with their advantages in shaping metals and improving mechanical properties. Key terms related to forging like dies, forgings, and defects in forged parts are also summarized.