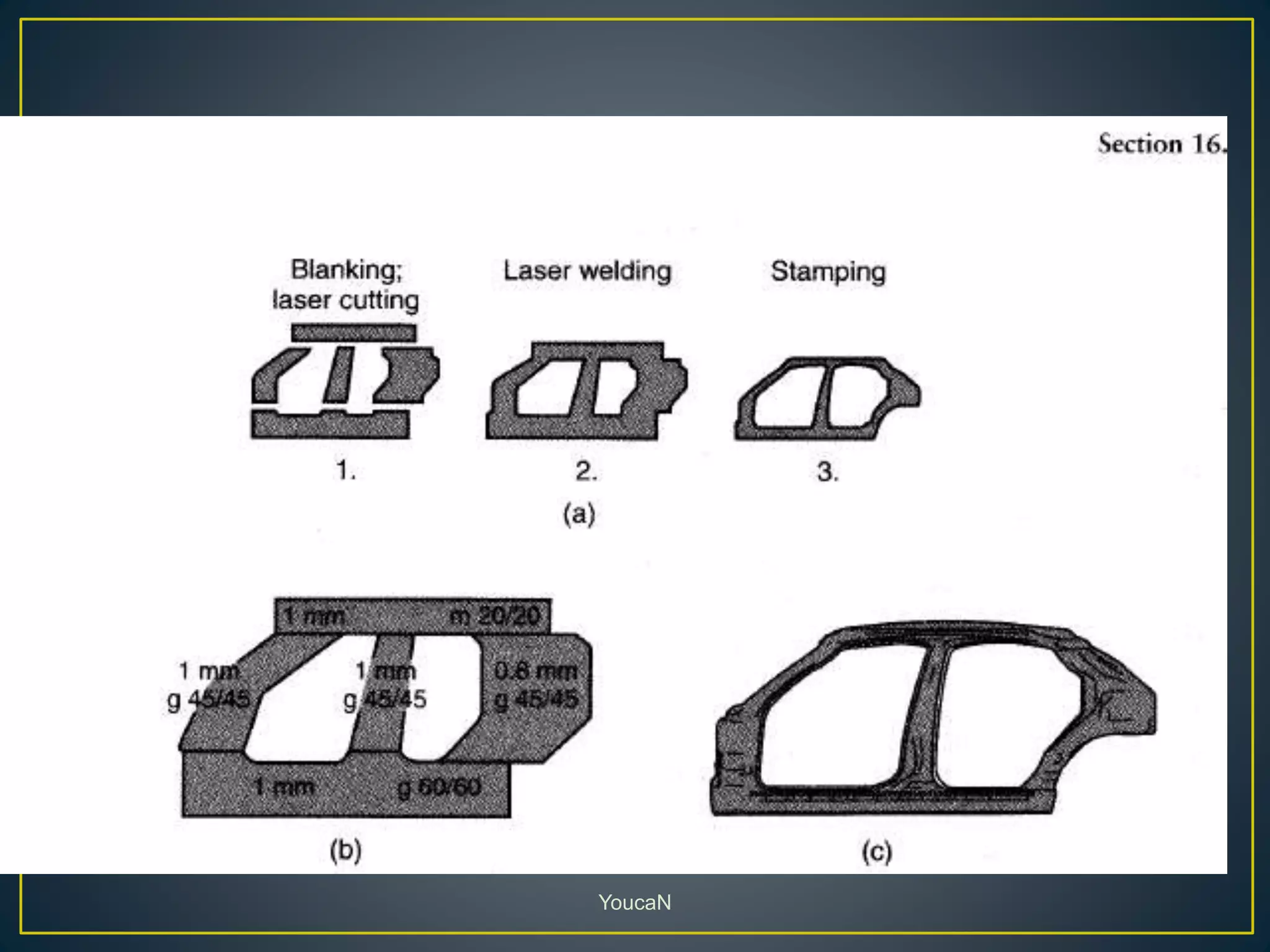

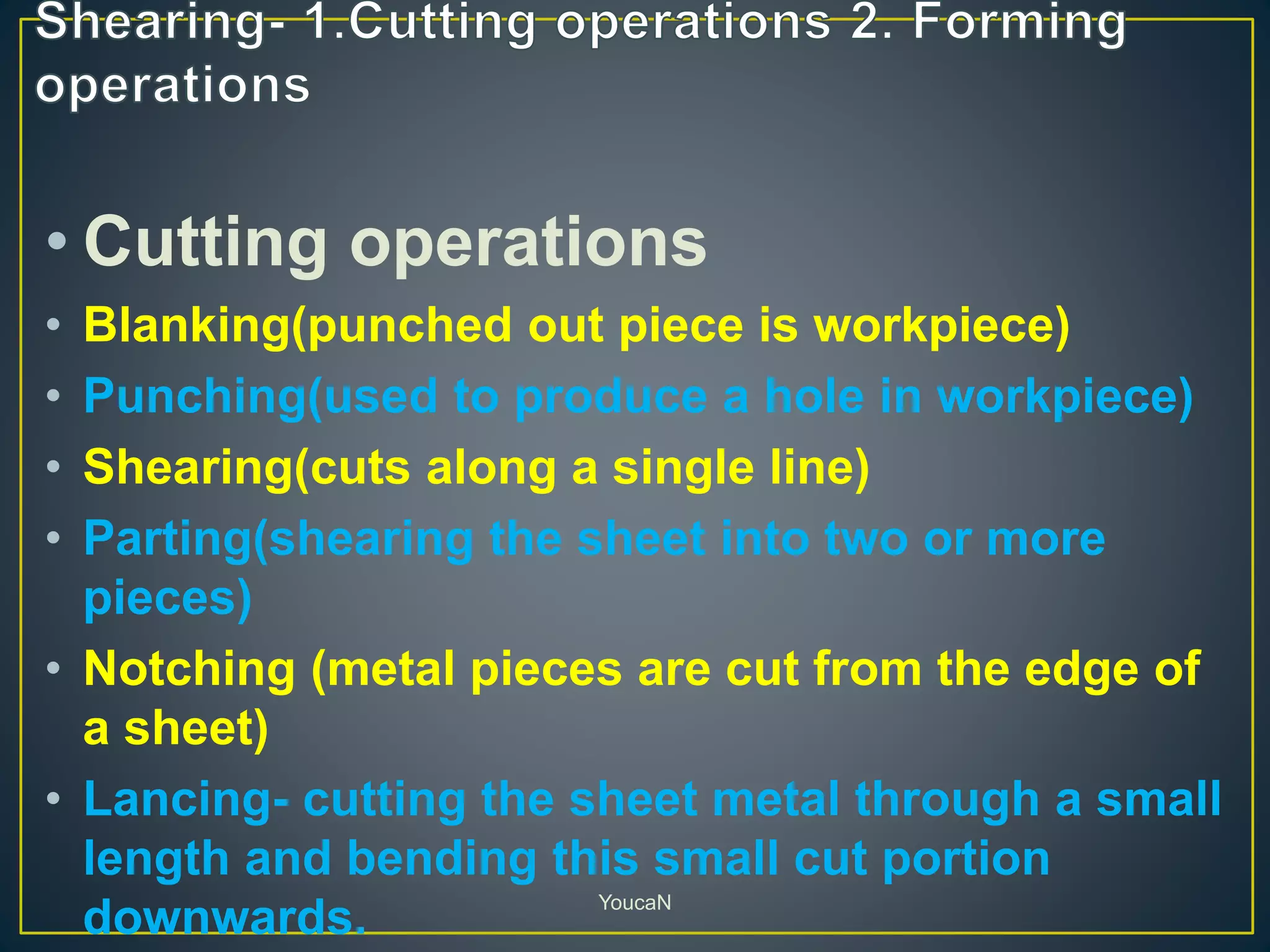

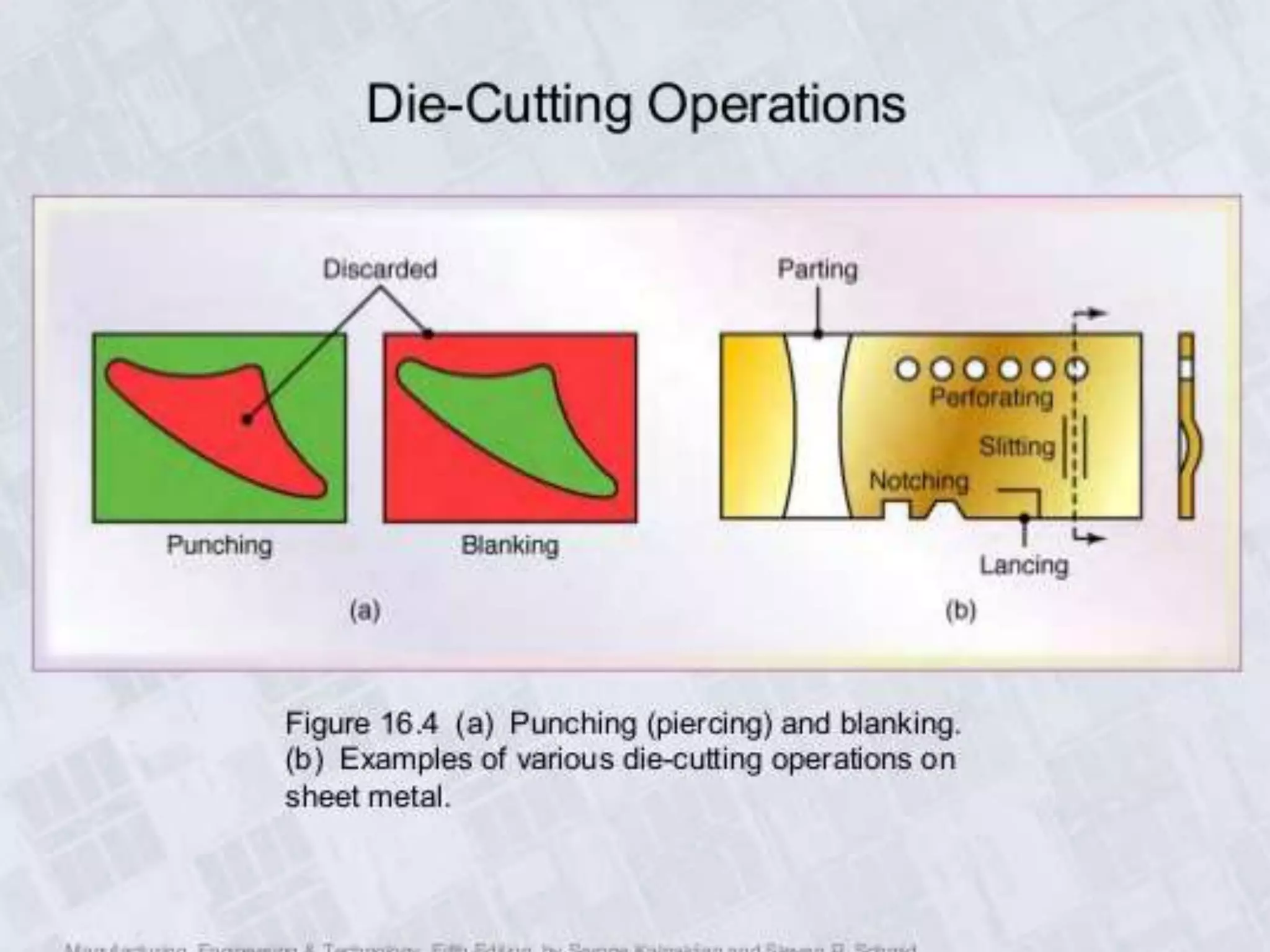

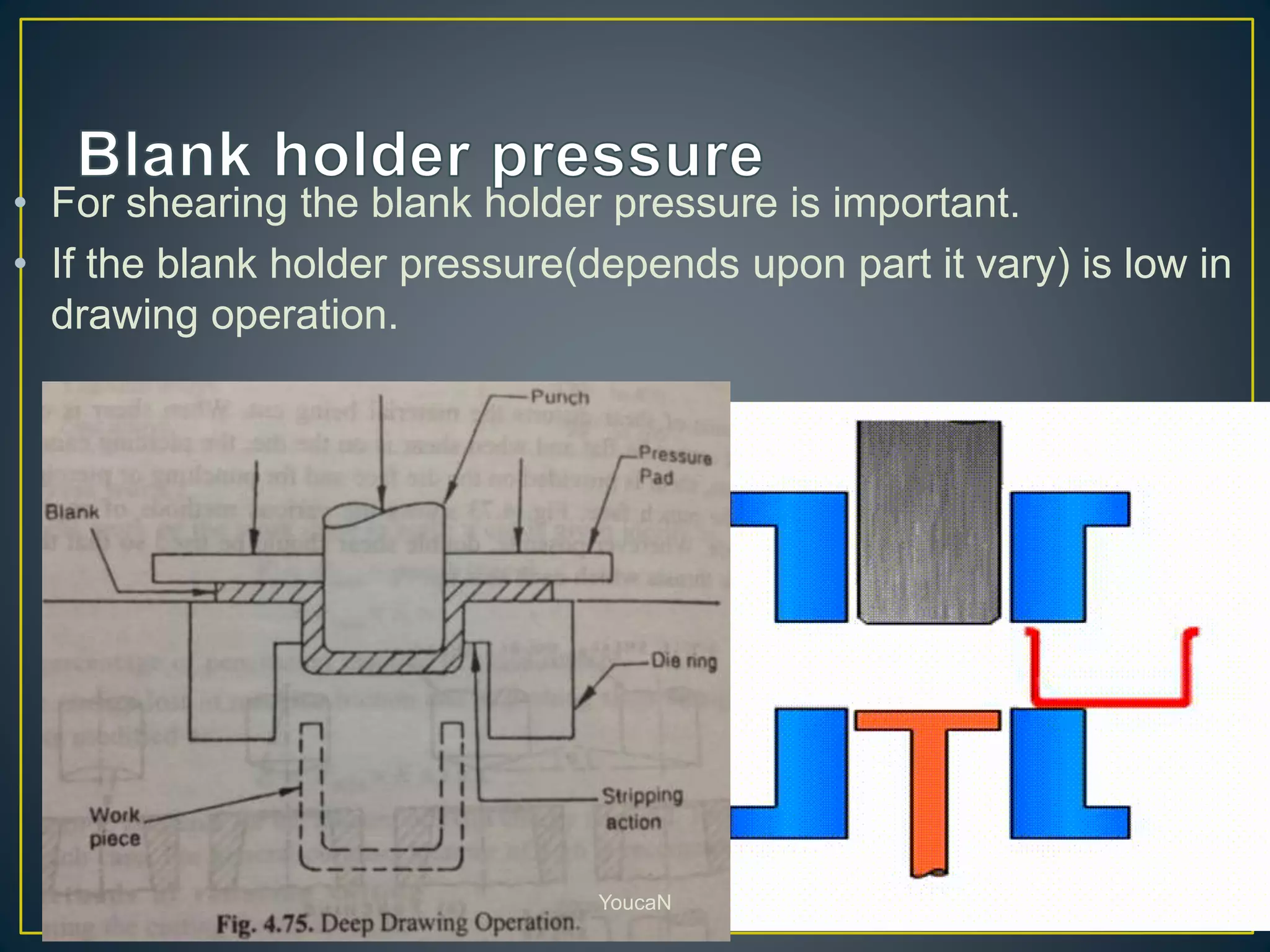

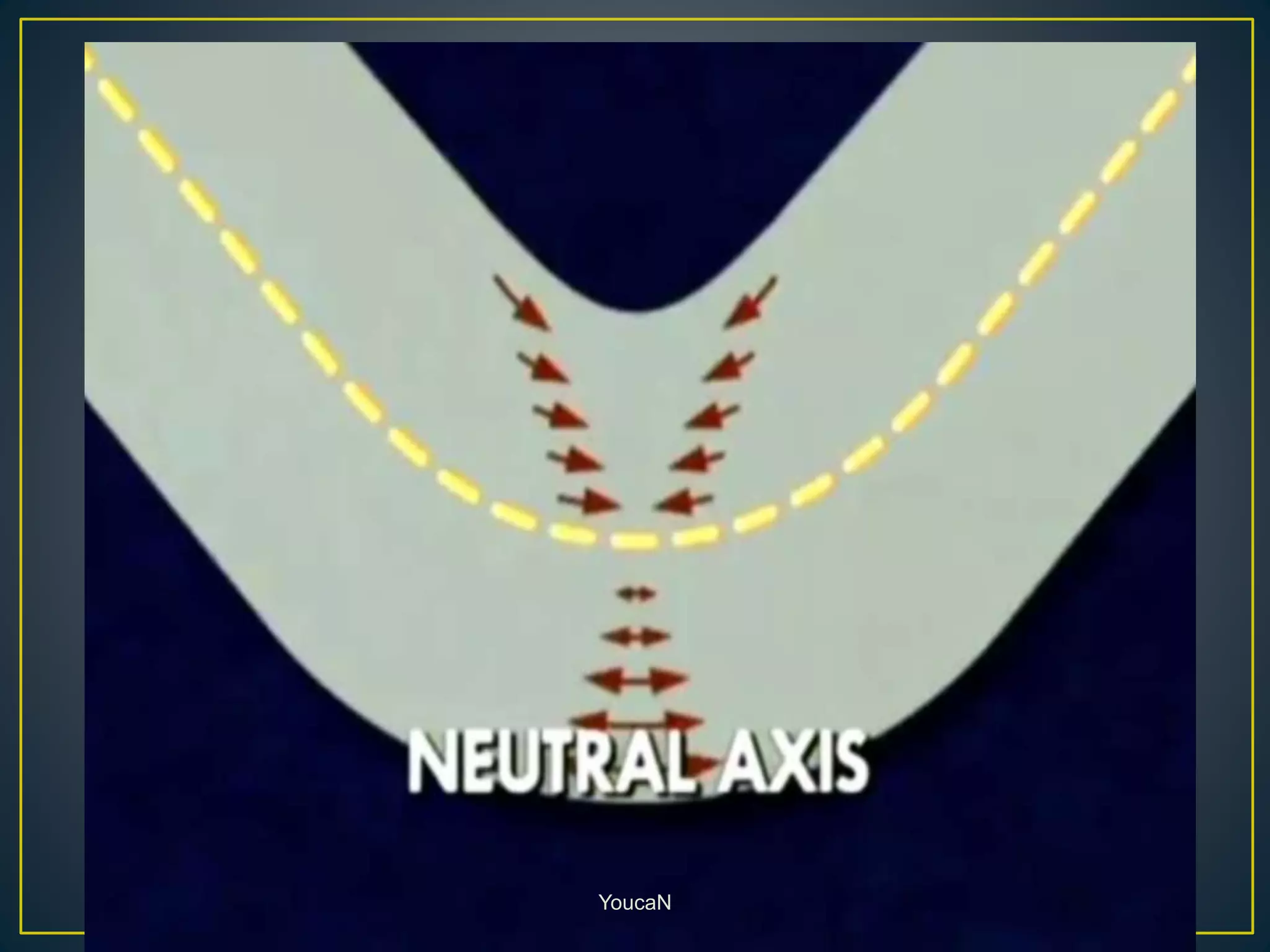

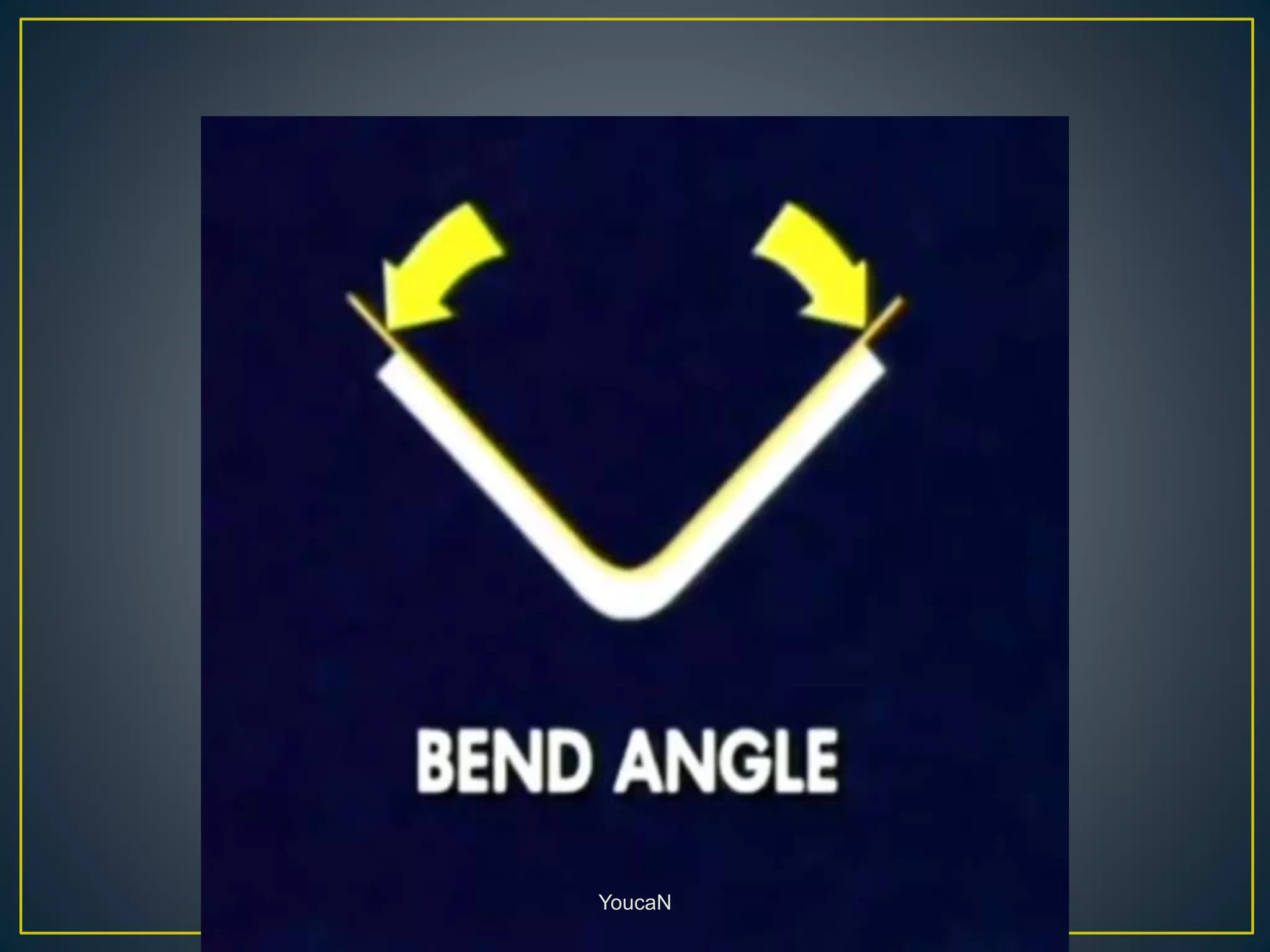

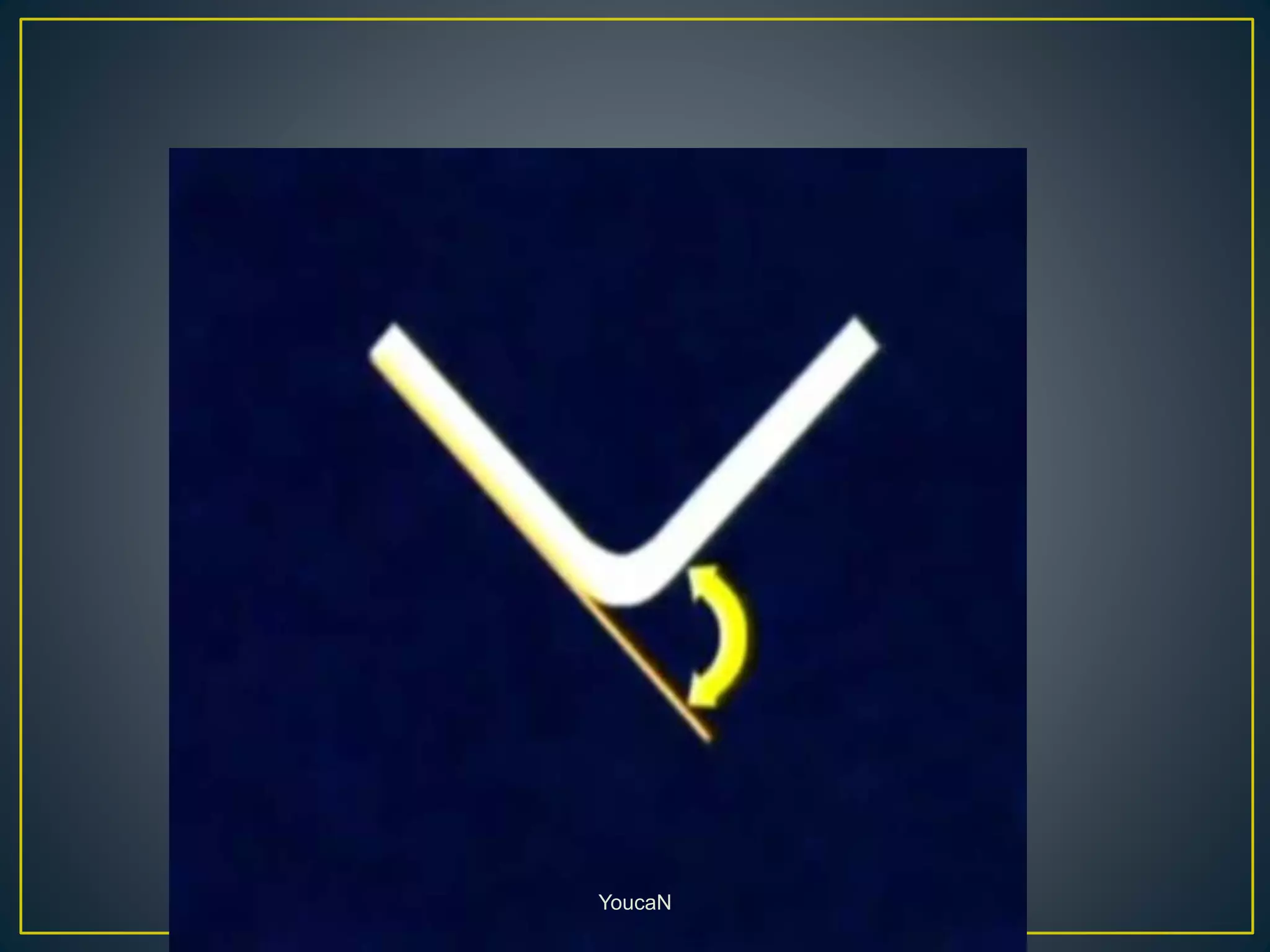

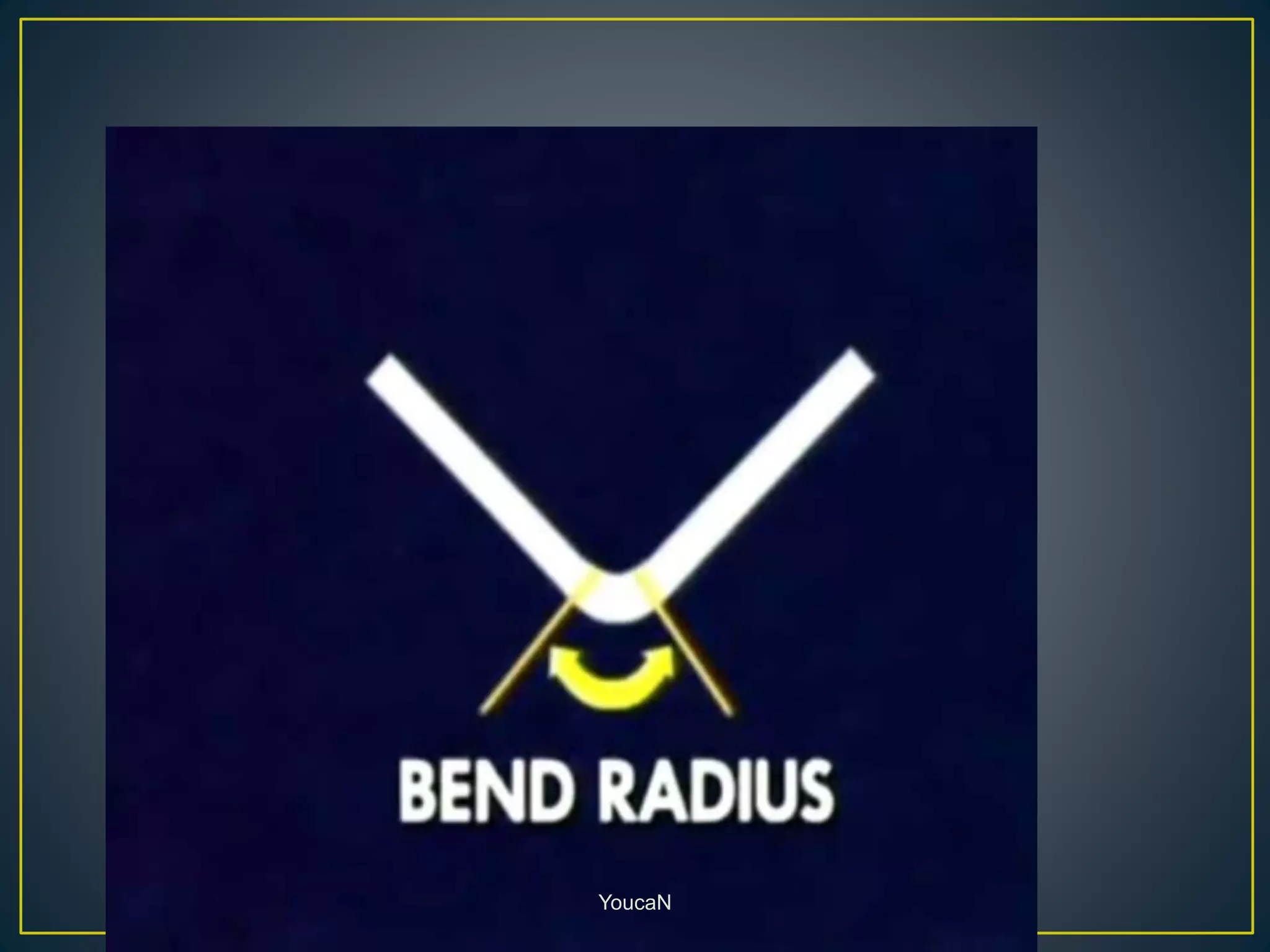

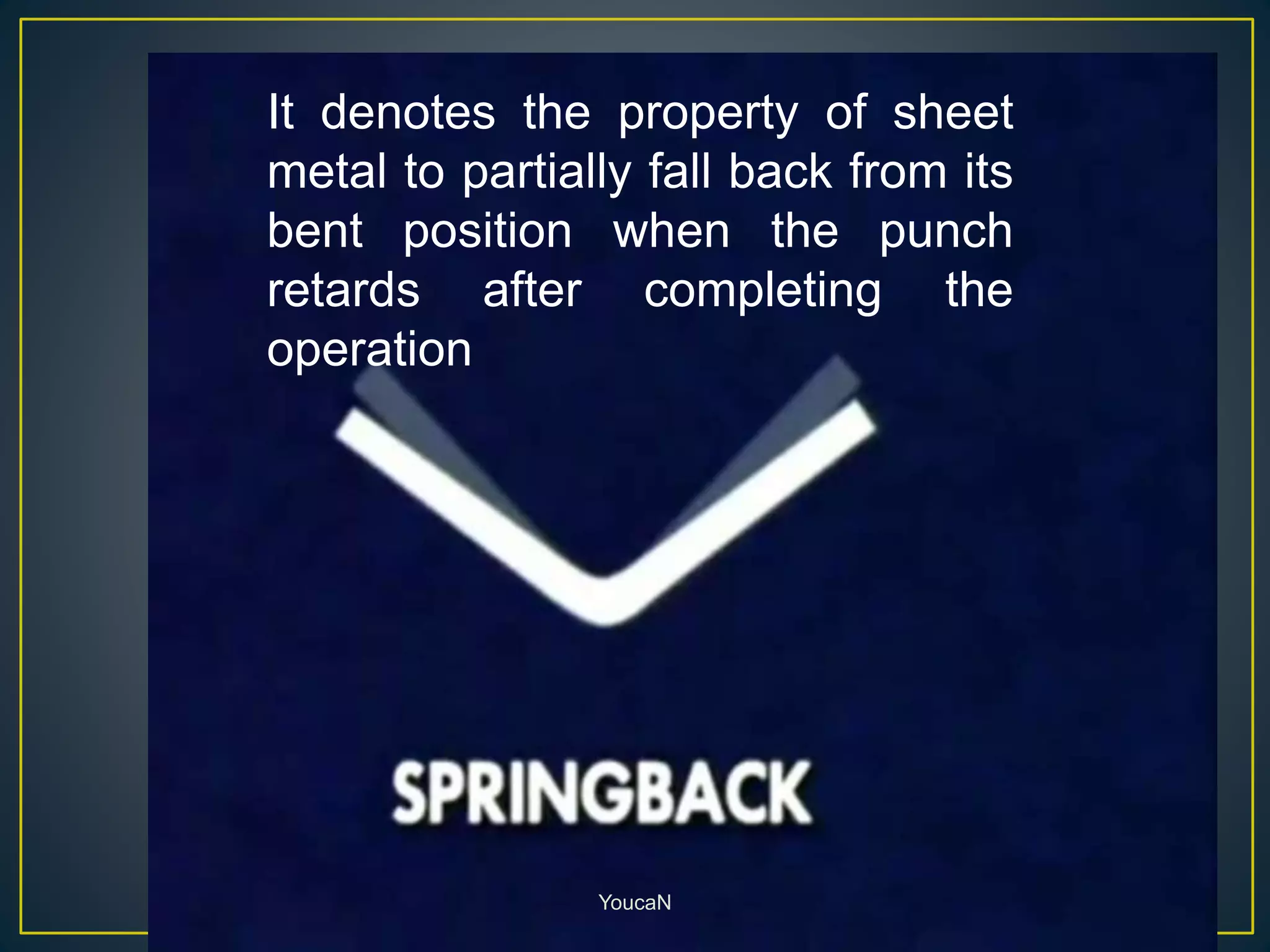

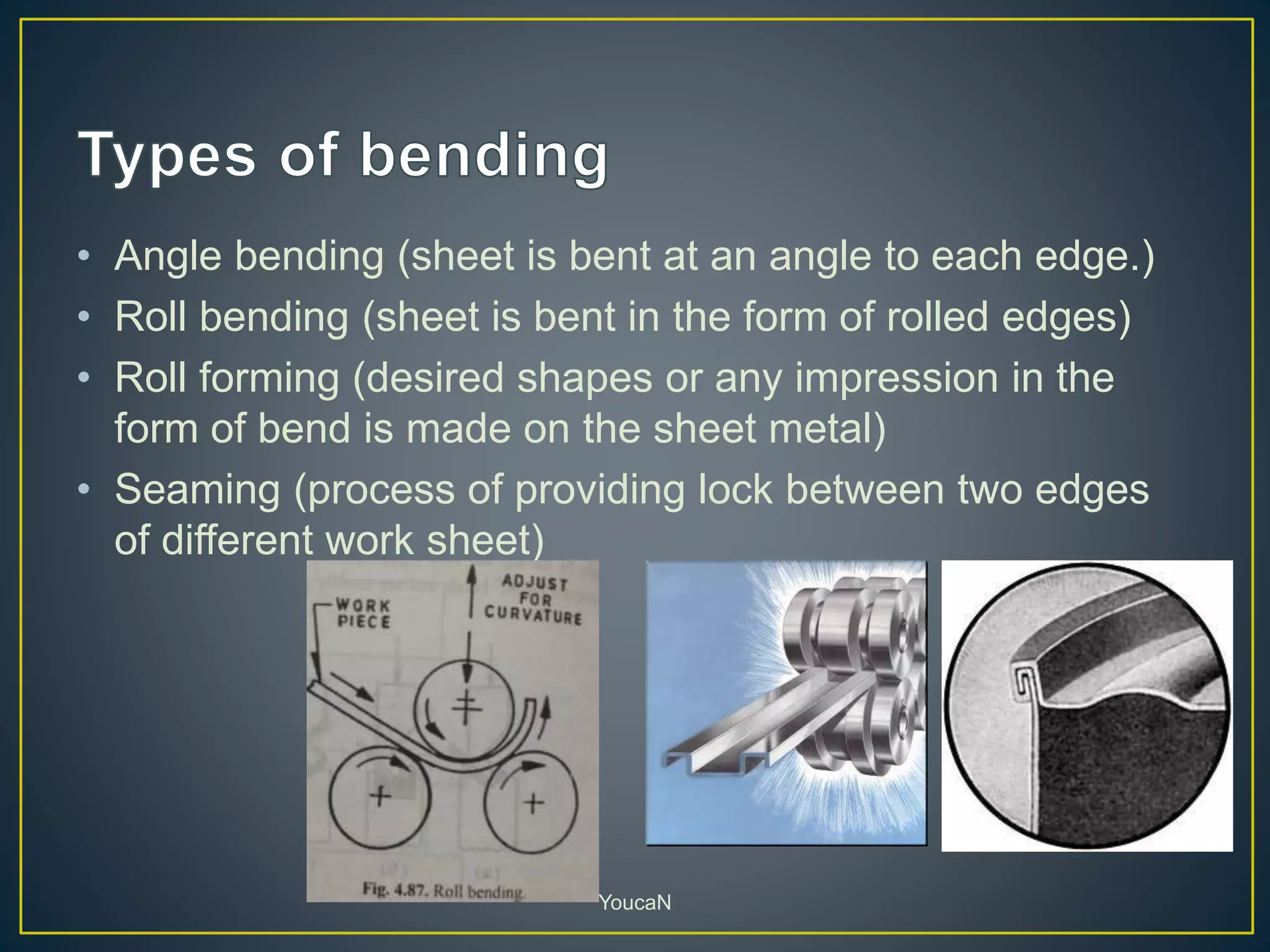

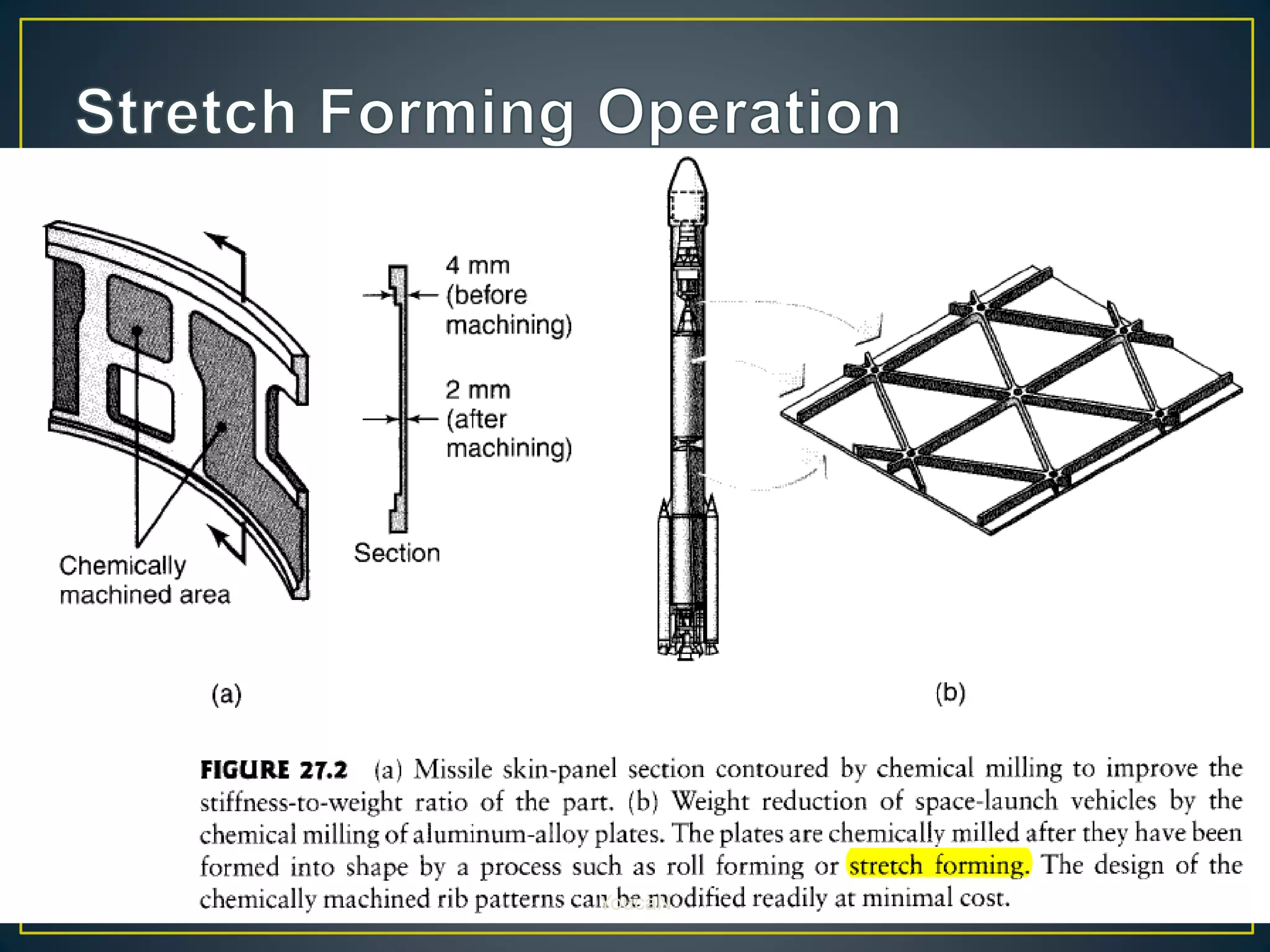

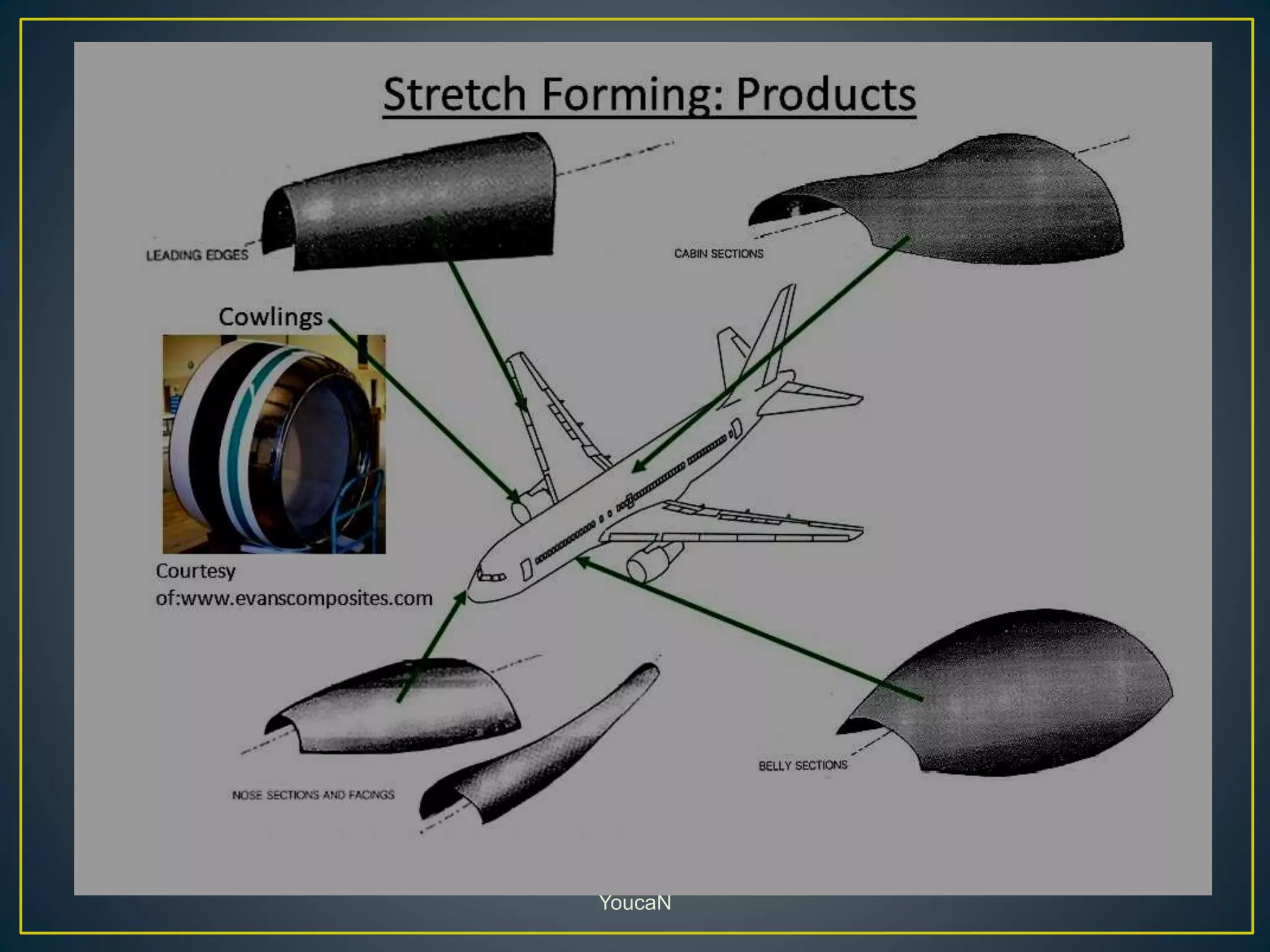

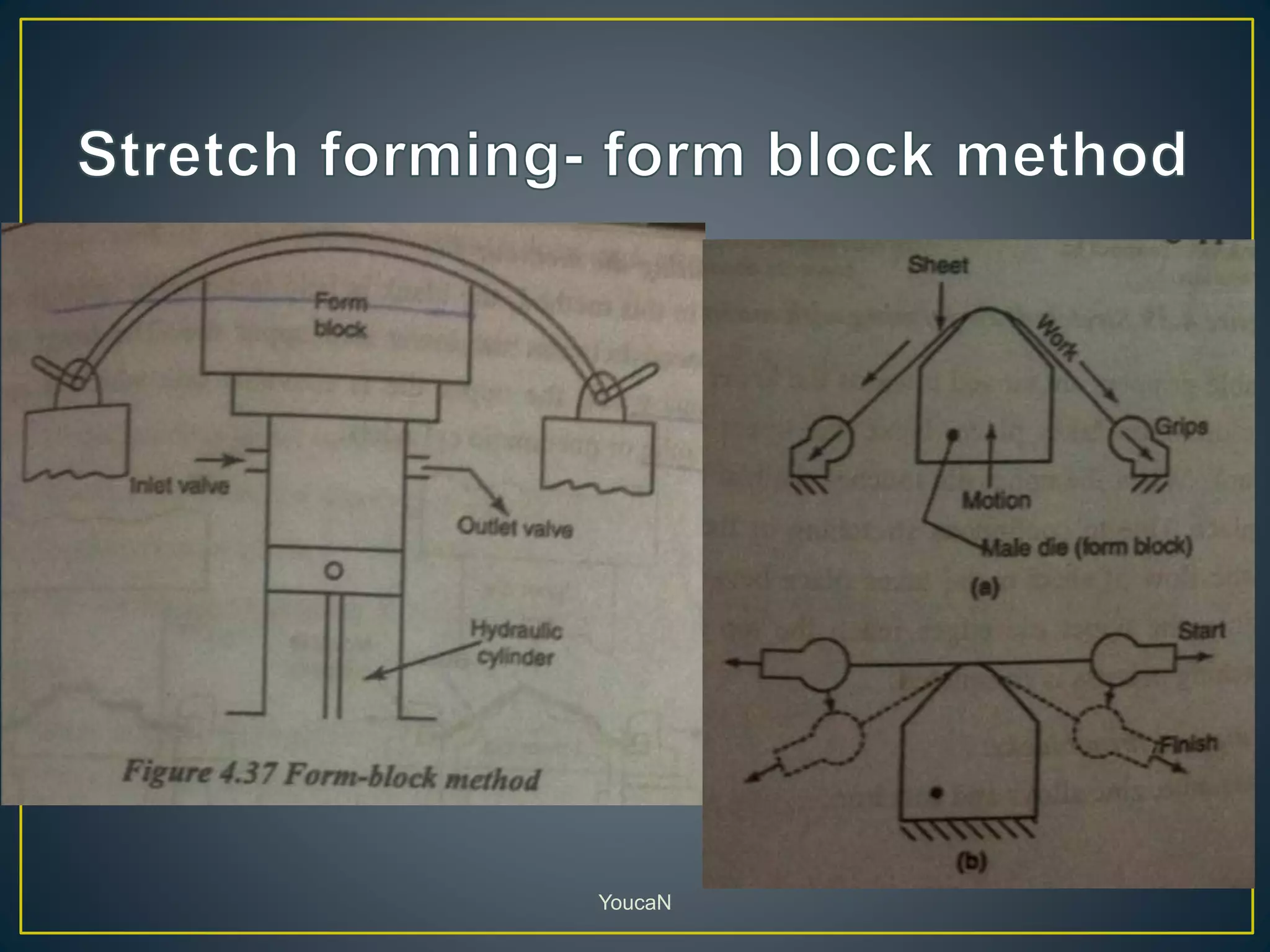

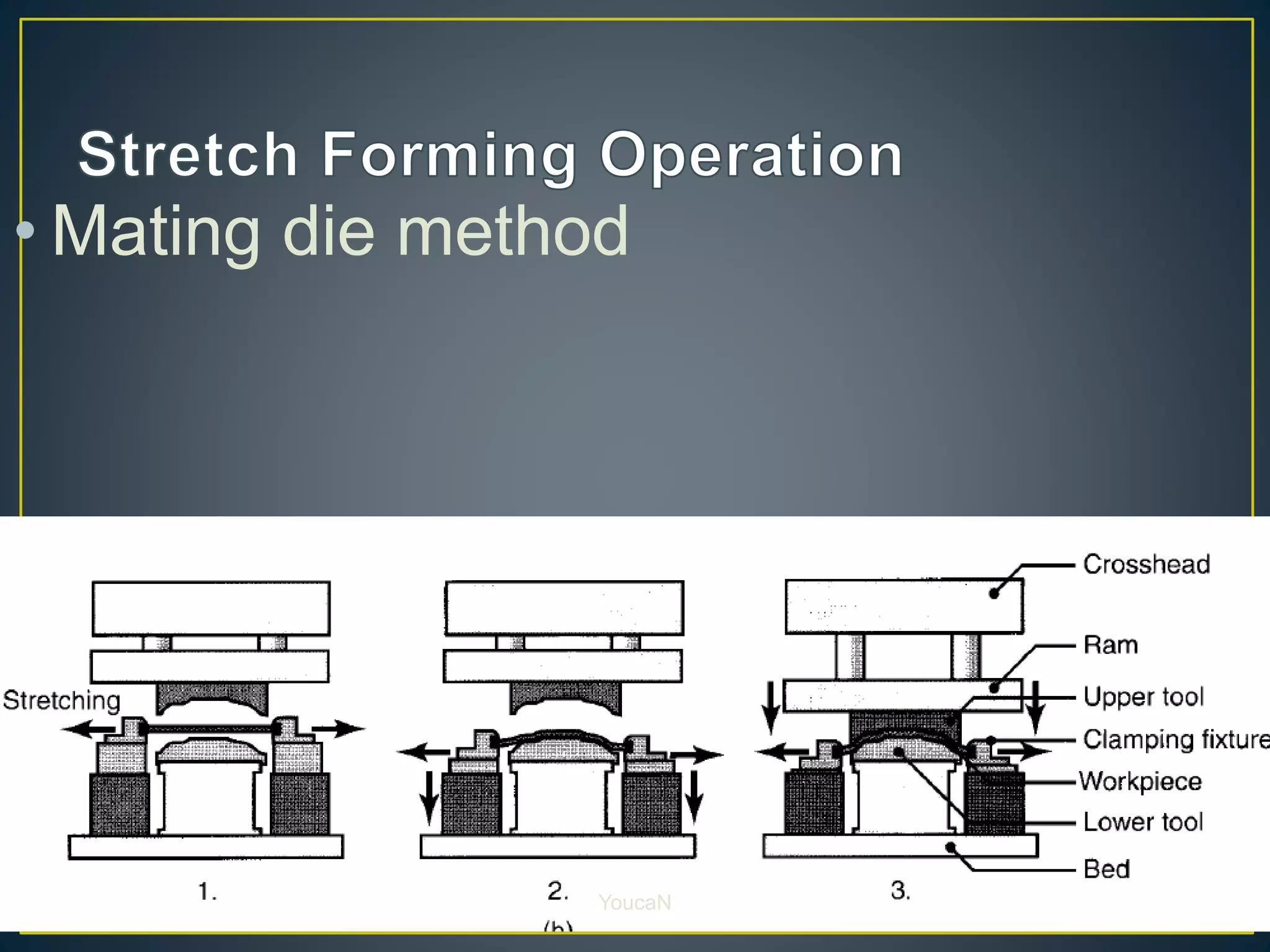

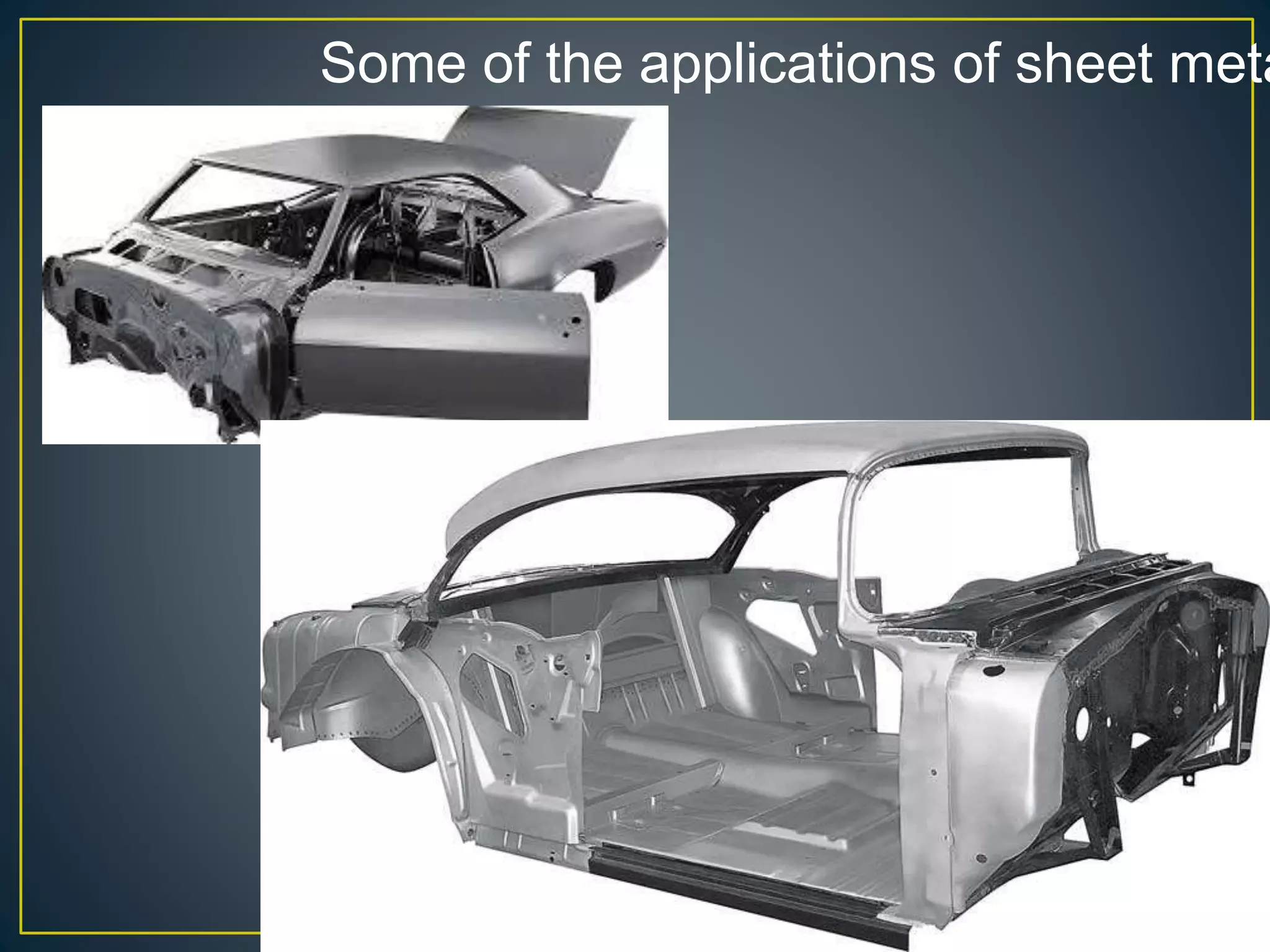

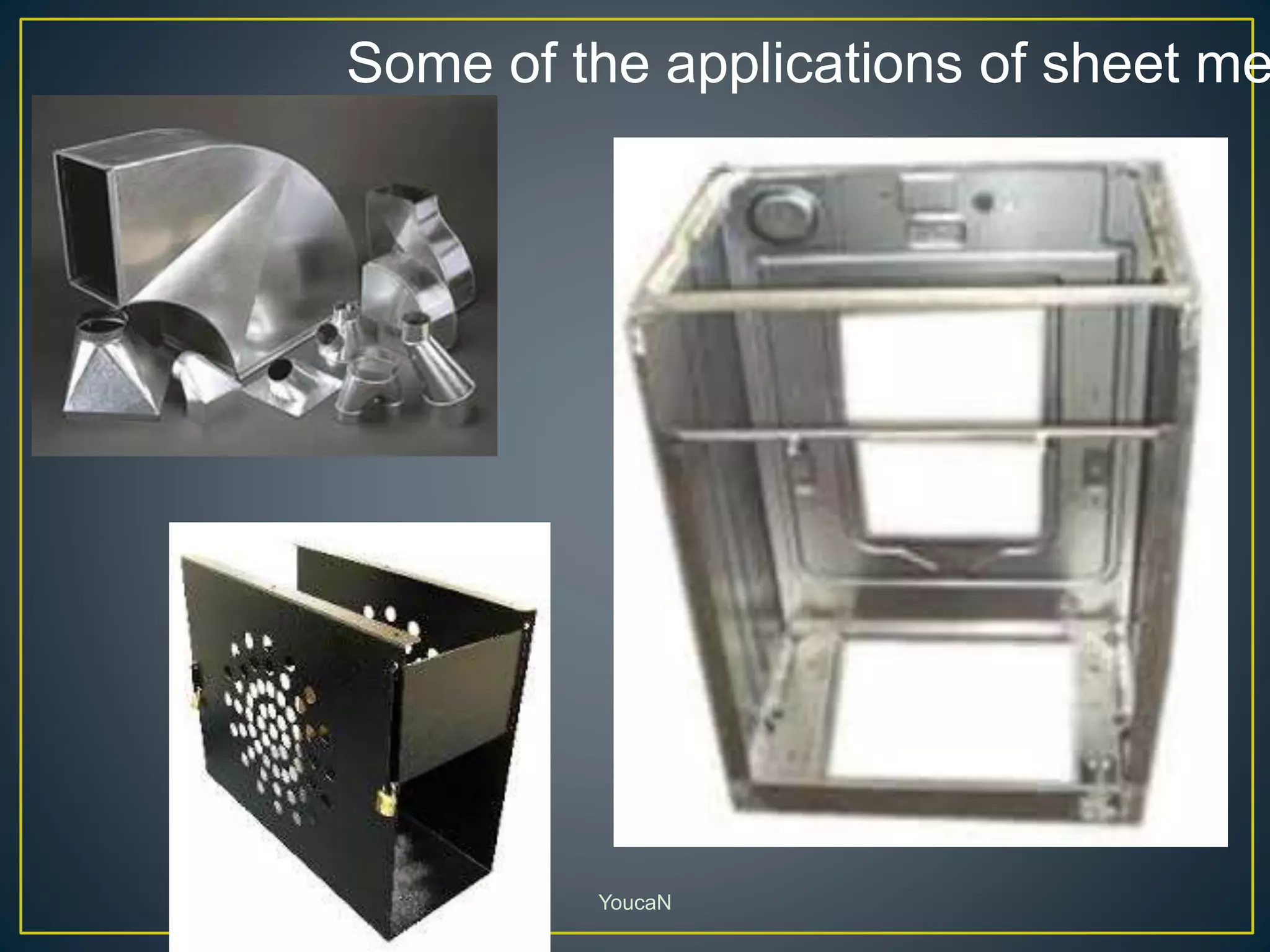

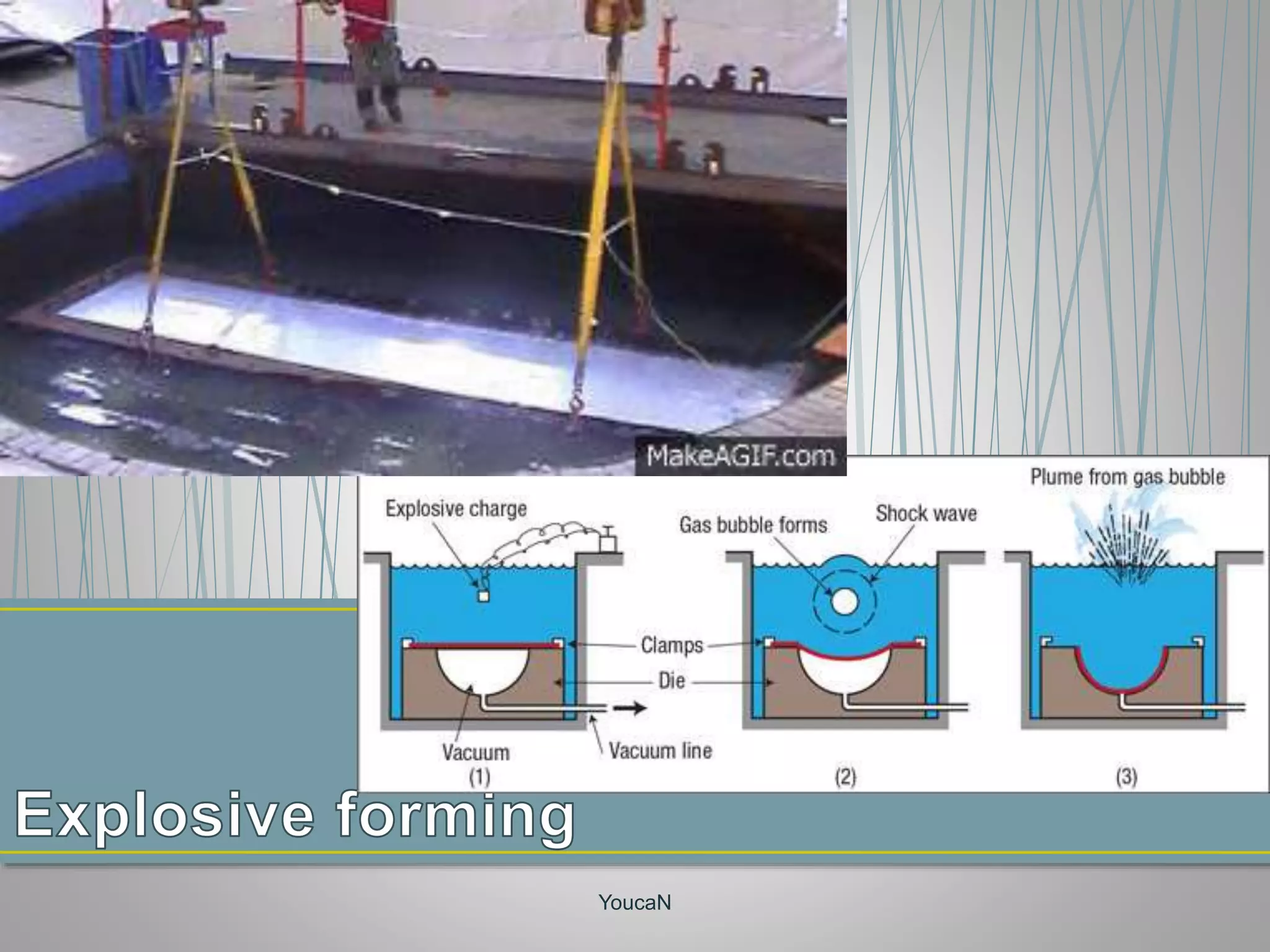

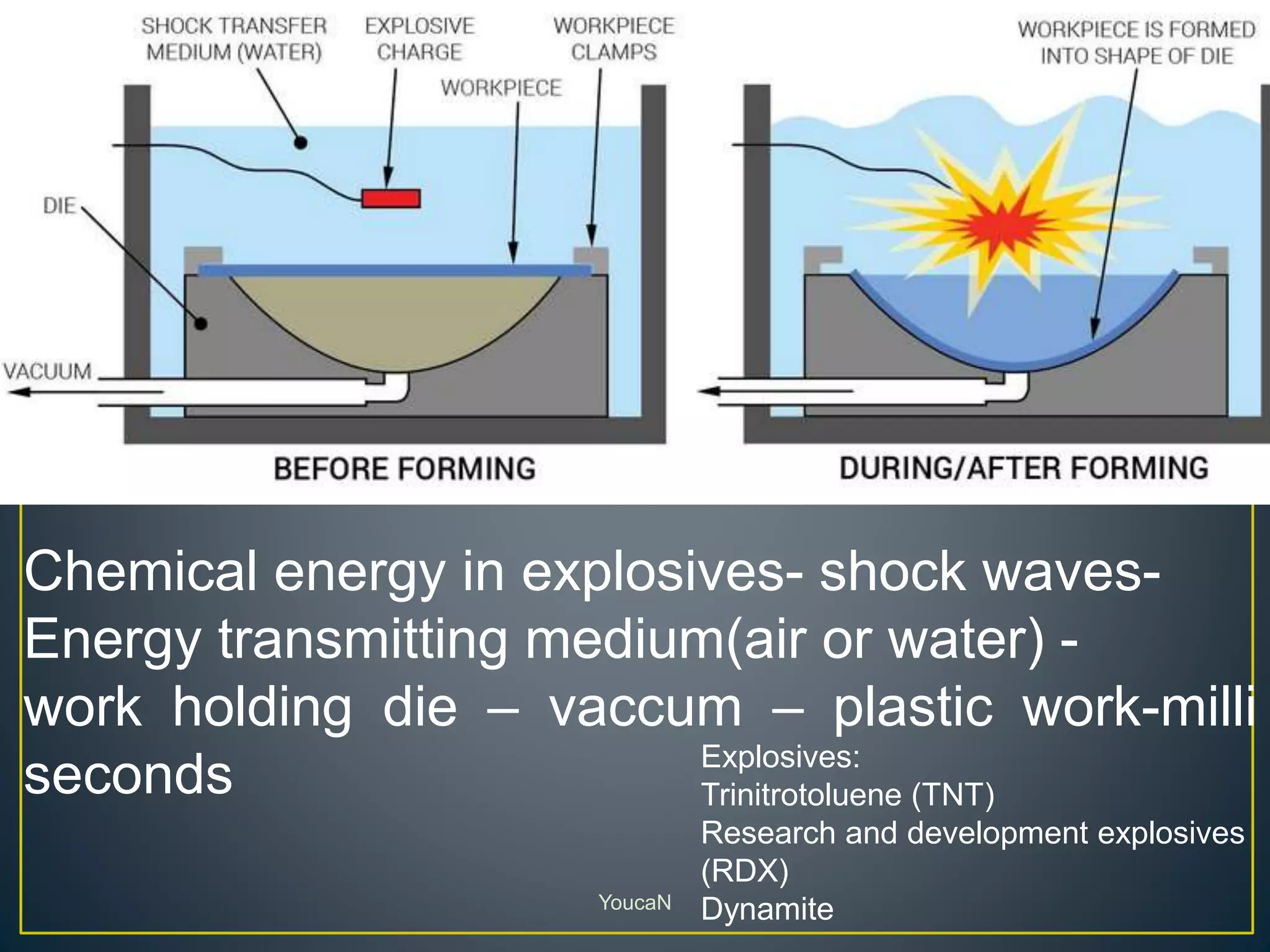

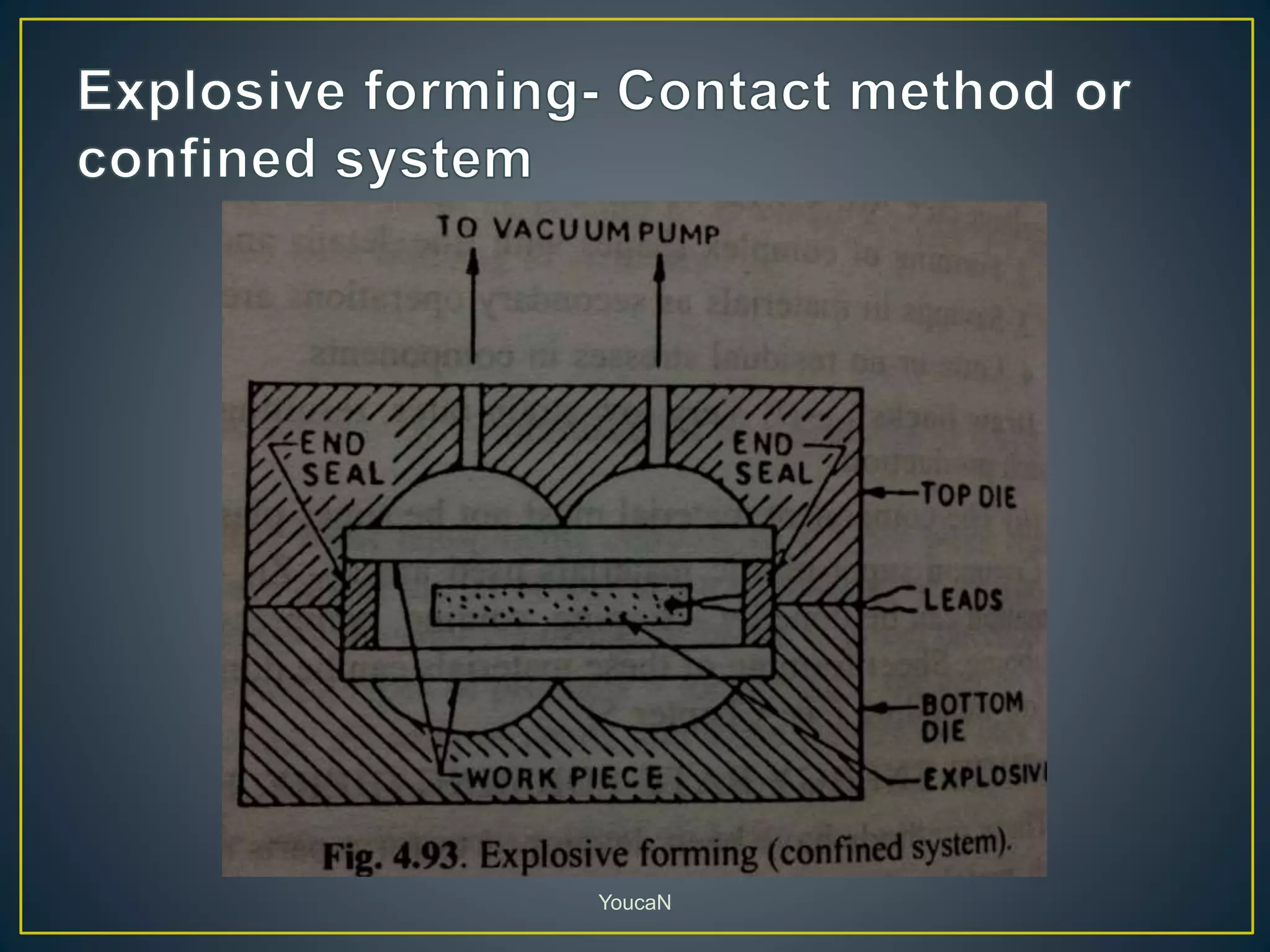

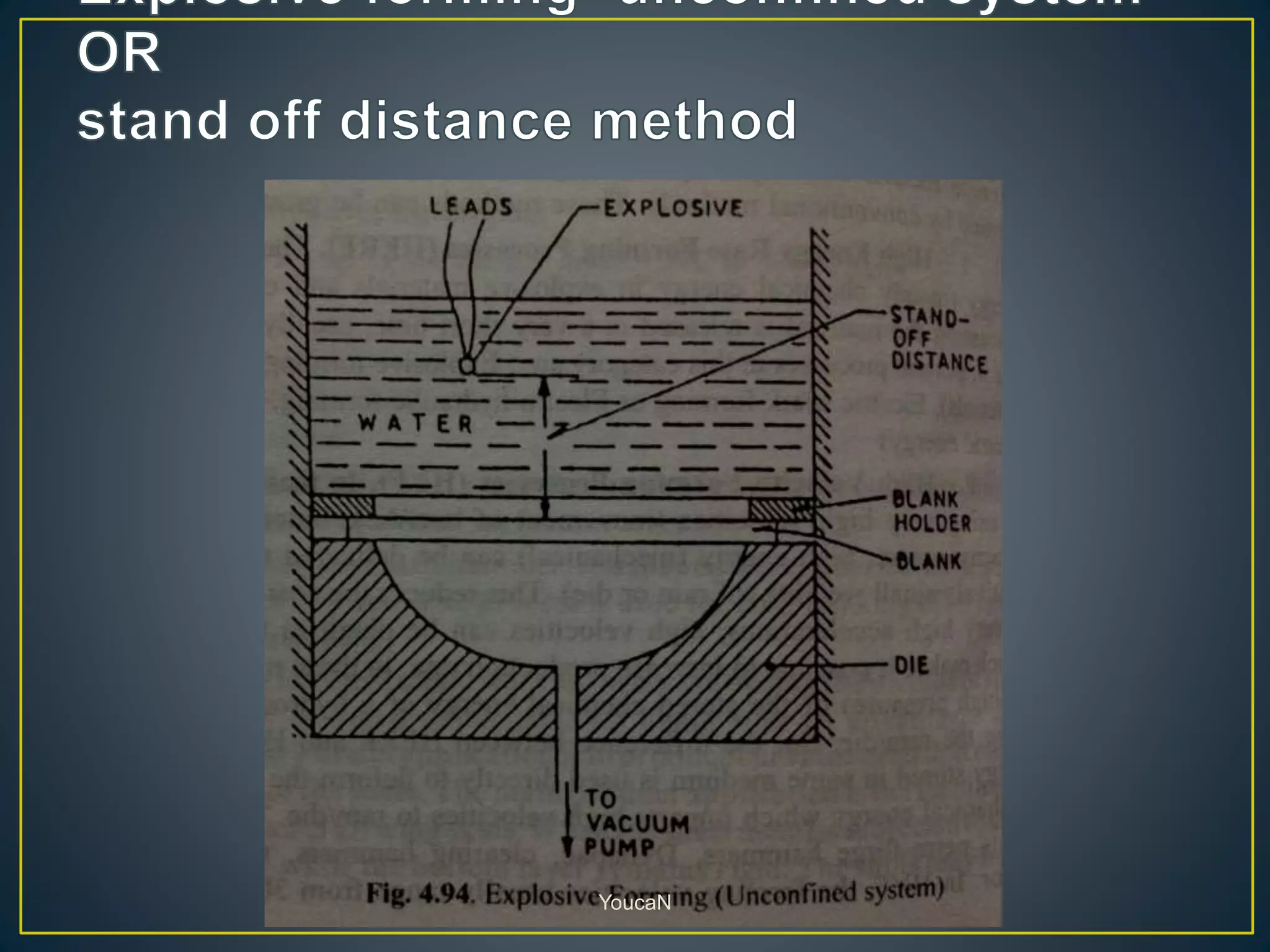

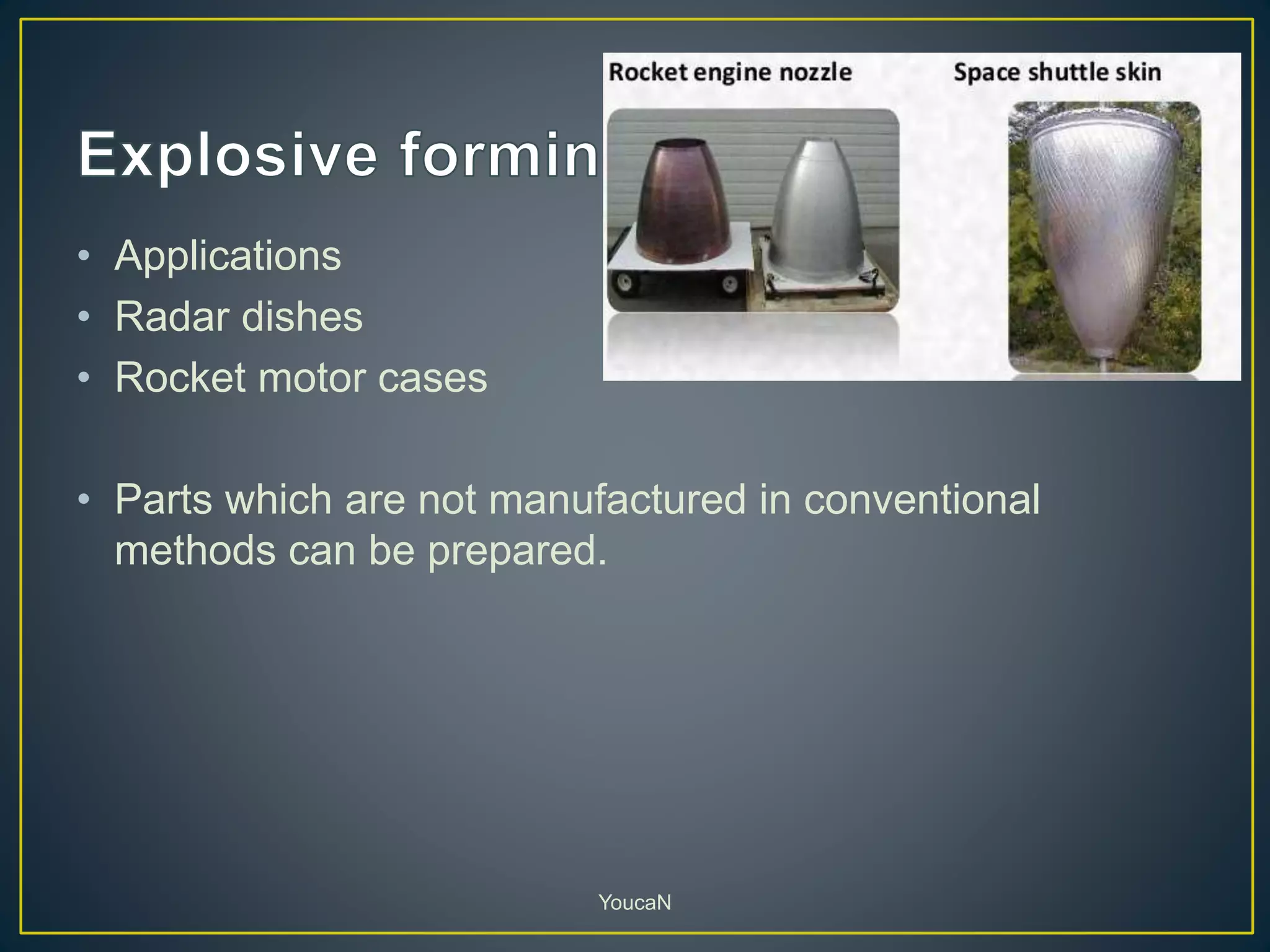

This document discusses various sheet metal forming processes. It describes operations like shearing, bending, drawing and stretch forming. It explains that sheet metal offers advantages of light weight and versatile shapes compared to casting/forging. Processes like explosive forming and magnetic pulse forming are also introduced for special sheet metal forming applications.