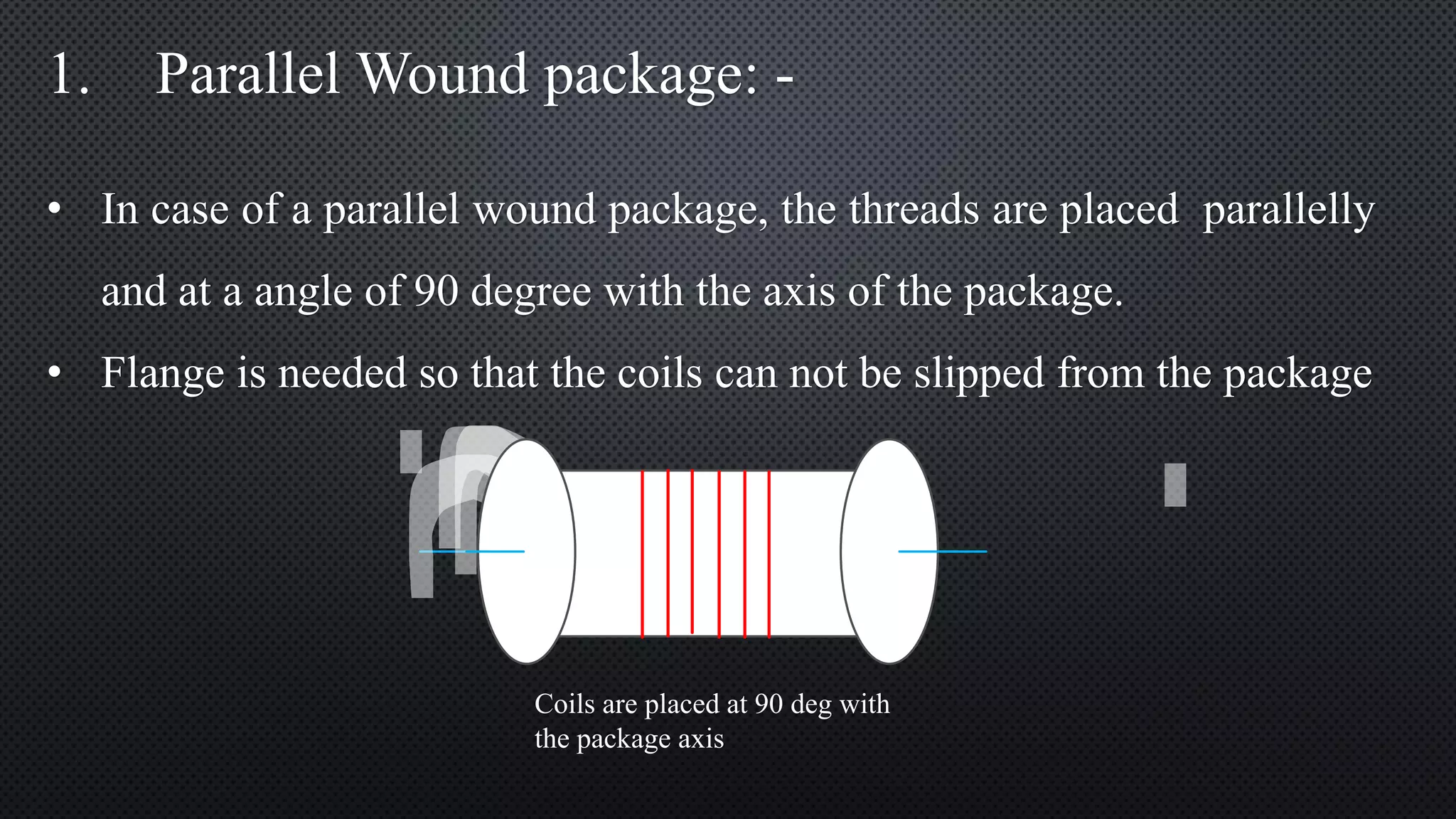

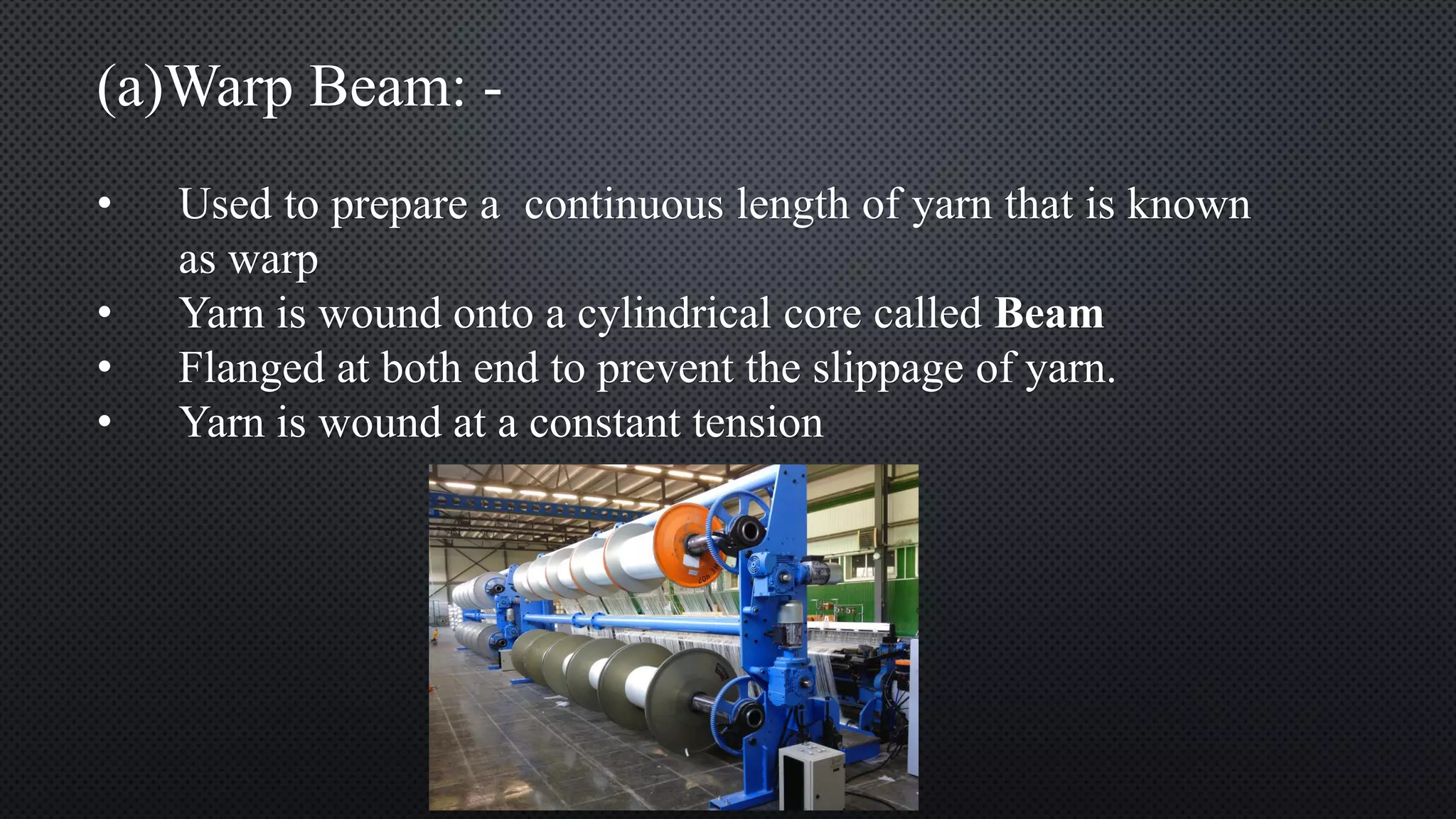

The document outlines three main types of yarn packages: parallel wound, near parallel wound, and cross wound. Each type has subcategories and specifications, such as warp and weavers beams for parallel wound packages, pirn and cop packages for near parallel packages, and cone and cheese packages for cross wound packages. Benefits and drawbacks of each package type are discussed, including stability, yarn withdrawal, and the need for flanges.