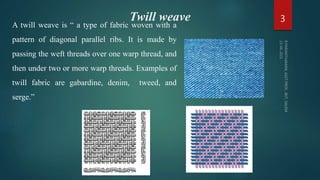

1. Twill weave is a type of fabric woven with a diagonal parallel pattern created by passing the weft over one warp thread and under two or more.

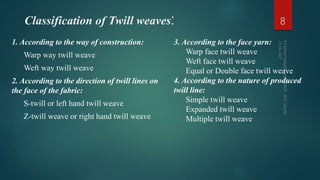

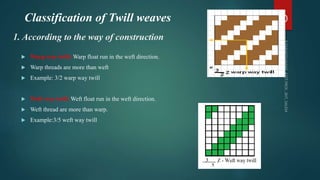

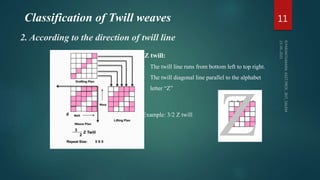

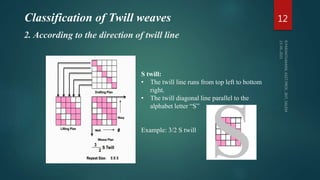

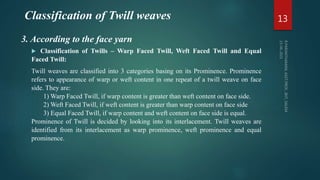

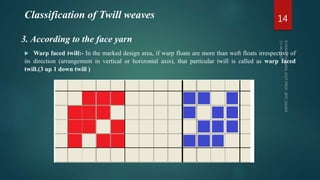

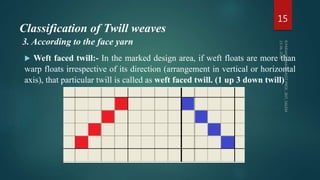

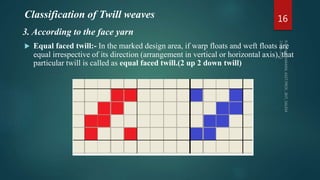

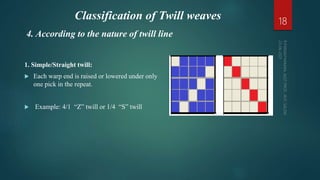

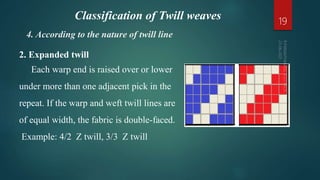

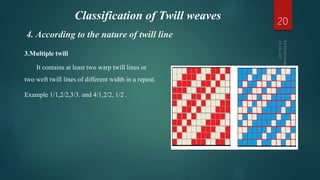

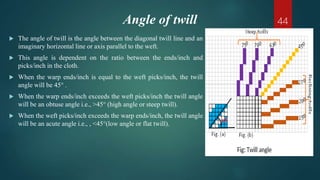

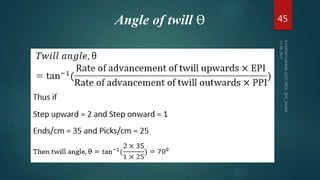

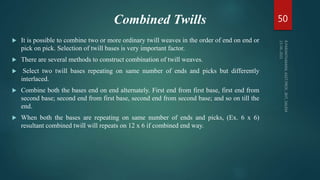

2. The document discusses the classification, features, and derivatives of twill weaves. Twill weaves are classified based on construction method, direction of twill lines, prominence of warp or weft threads, and nature of the twill line.

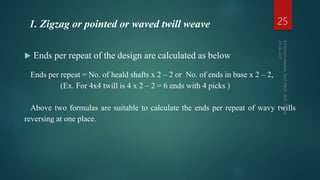

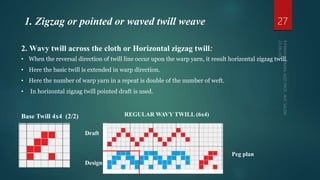

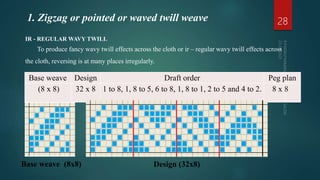

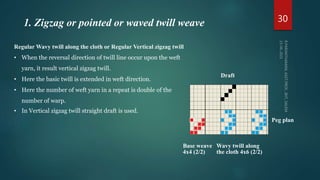

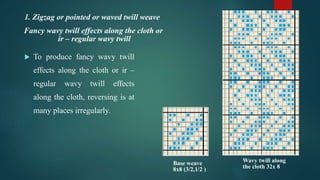

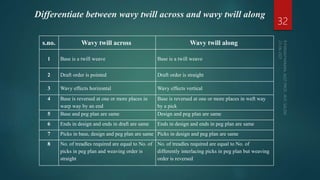

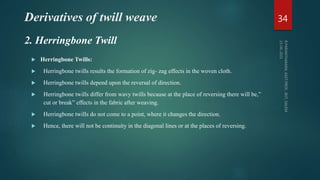

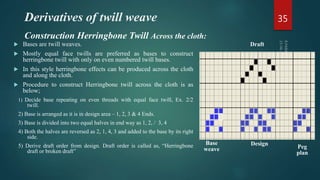

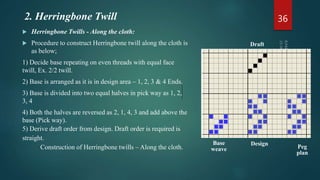

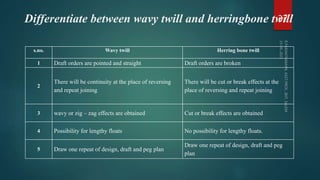

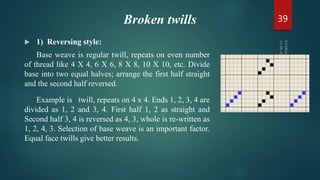

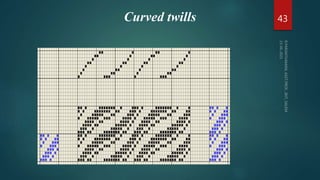

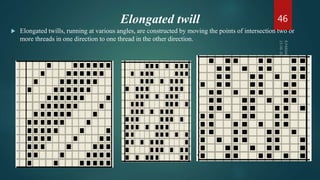

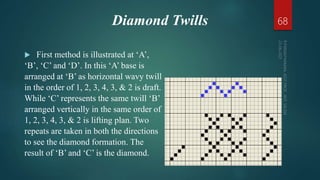

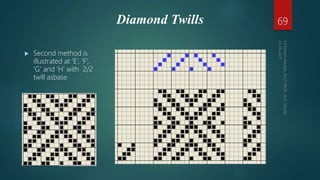

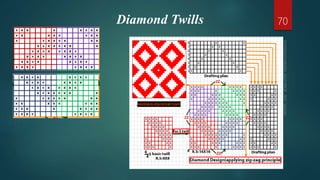

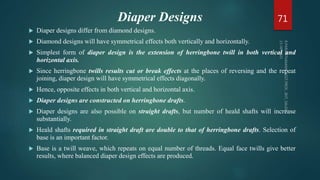

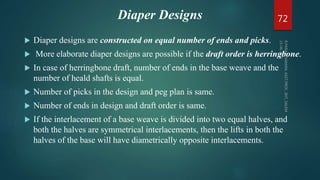

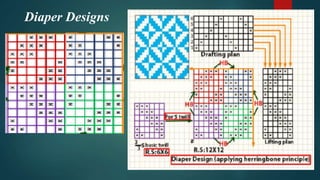

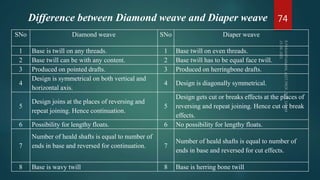

3. Derivatives include zigzag, herringbone, broken, and curved twills created by reversing the twill direction periodically. Wavy twills introduce horizontal or vertical zigzag patterns by reversing the twill across or along the fabric.