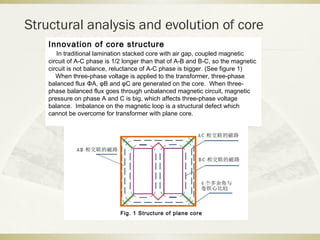

The document defines a transformer with a three-dimensional wound core, which is composed of three single wound core frames and offers a more efficient structure compared to traditional stacked core transformers. It highlights advantages such as reduced manufacturing costs, improved performance, and better energy efficiency, including a significant decrease in no-load current and noise. Overall, the innovation in core structure represents a shift towards more sustainable and economically viable transformer technology.