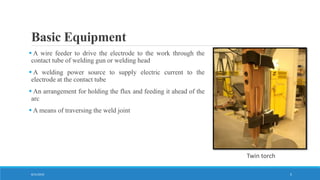

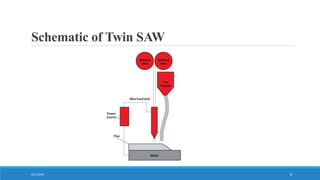

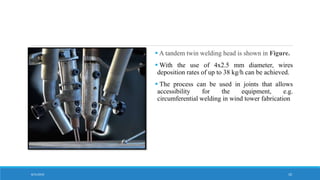

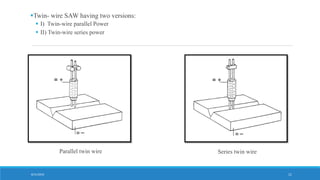

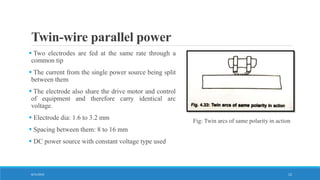

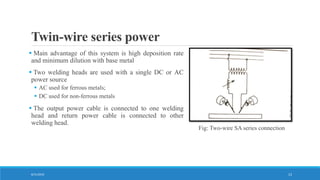

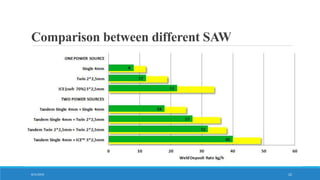

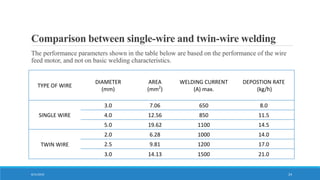

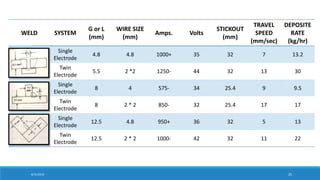

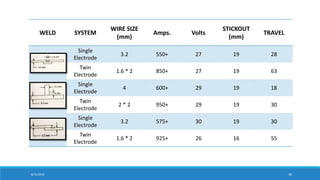

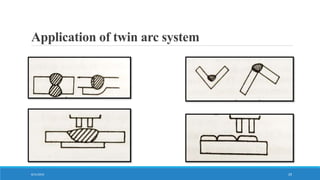

Twin submerged arc welding involves feeding two wires through the same contact tip using a single power source. This increases deposition rates over single-wire welding by 30-40% without significantly higher costs. The two wires can be arranged side by side or one behind the other. For even higher deposition, tandem twin welding uses four wires fed from two welding heads powered by a single source. This process can deposit over 38kg of weld metal per hour. Twin submerged arc welding is used for high-speed fillet welding and butt welding when high productivity is required.