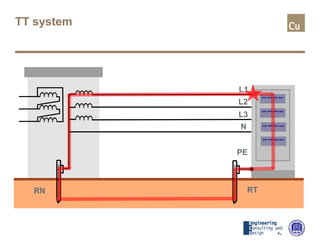

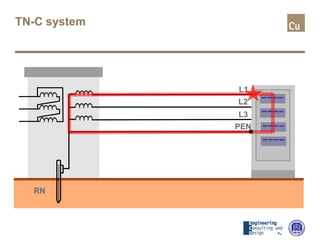

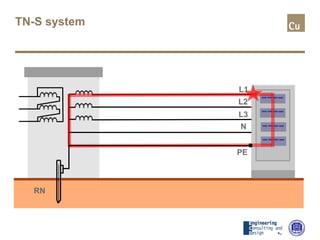

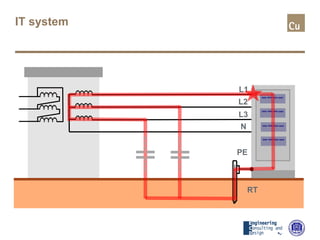

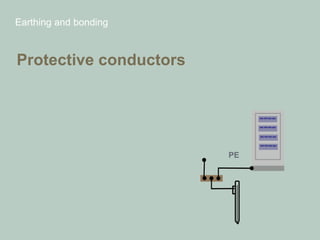

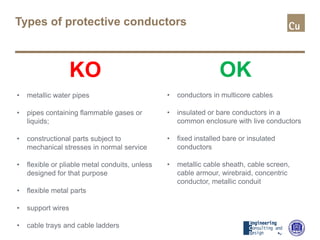

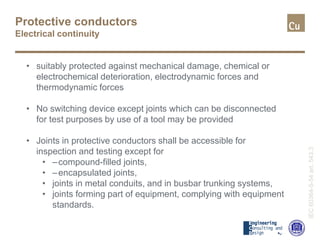

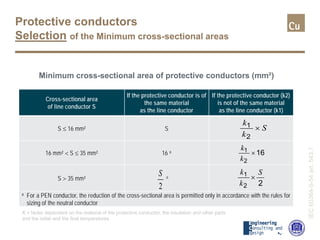

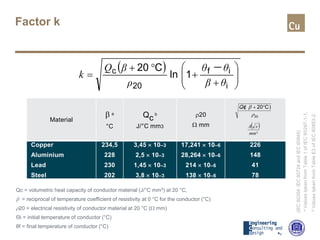

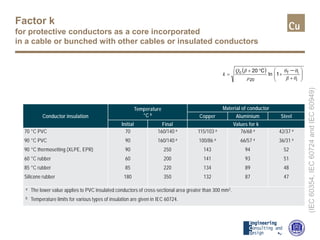

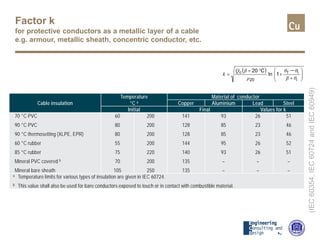

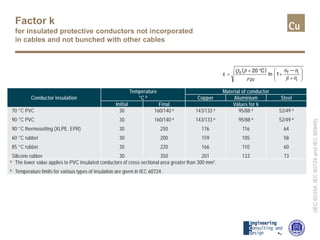

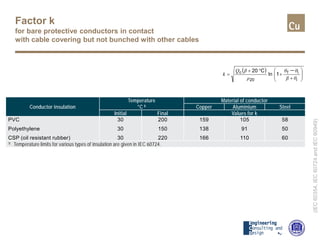

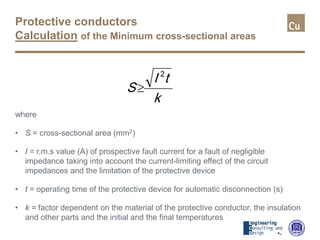

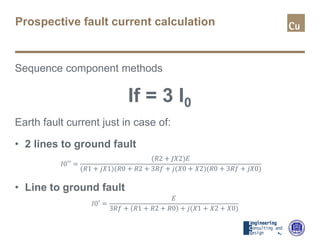

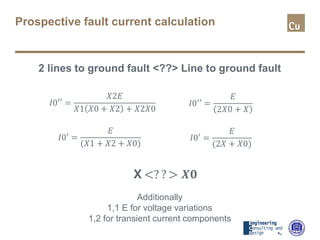

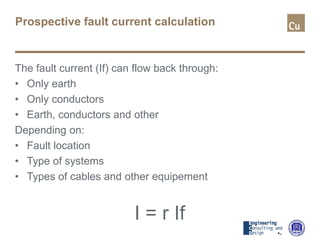

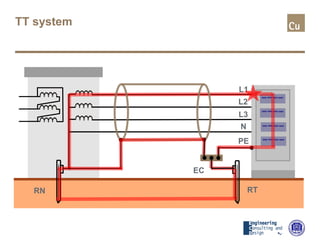

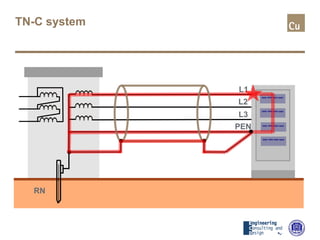

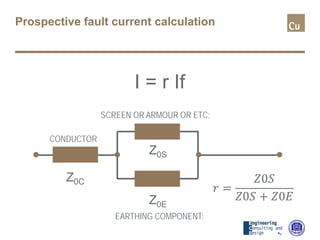

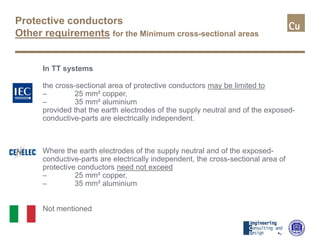

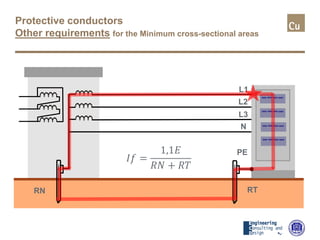

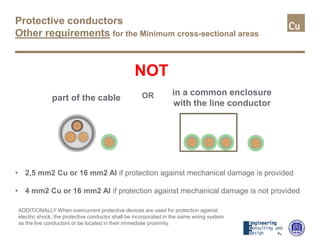

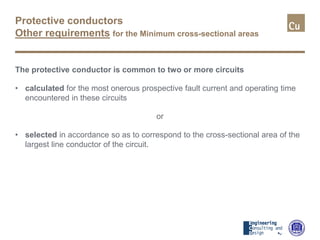

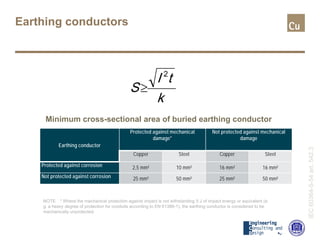

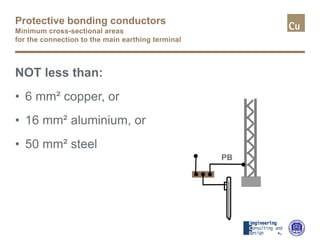

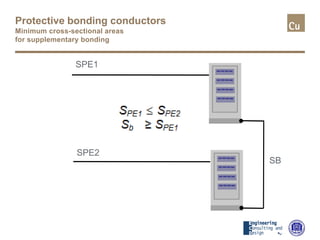

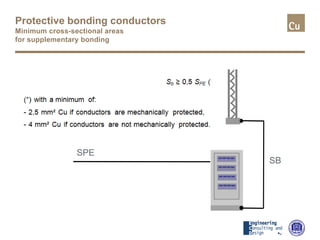

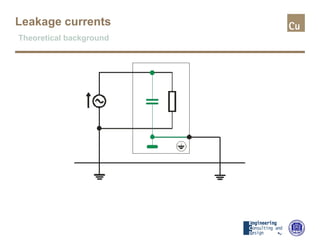

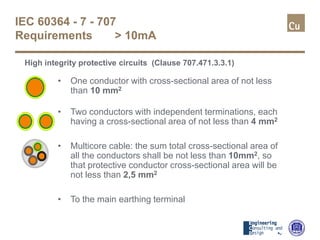

This document discusses earthing and bonding. It defines key terms like protective conductor, earthing conductor, and equipotential bonding. It describes different electrical system types like TT, TN-C, TN-S, and IT. It discusses general requirements for earthing arrangements and protective conductors. Protective conductors must provide reliable connection to earth and be suitably protected. Minimum cross-sectional areas for protective conductors depend on line conductor size and prospective fault current calculation factors. The document provides factors and formulas for calculating prospective fault current and sizing protective conductors accordingly.

![Definitions

EXPOSED-CONDUCTIVE-PART

conductive part of equipment which

can be touched and which is not

normally live, but which can become

live when basic insulation fails

[IEV 195-06-10]](https://image.slidesharecdn.com/earthingandbonding-190616163015/85/Earthing-and-bonding-Power-cables-5-320.jpg)

![Definitions

PROTECTIVE CONDUCTOR

conductor provided for

purposes of safety, for

example protection against

electric shock

[IEV 195-02-09]](https://image.slidesharecdn.com/earthingandbonding-190616163015/85/Earthing-and-bonding-Power-cables-6-320.jpg)

![Definitions

MAIN EARTHING TERMINAL

(main earthing busbar)

terminal or busbar which is part

of the earthing arrangement of

an installation enabling the

electric connection of a number

of conductors for earthing

purposes

[IEV 195-02-33]](https://image.slidesharecdn.com/earthingandbonding-190616163015/85/Earthing-and-bonding-Power-cables-7-320.jpg)

![Definitions

EARTHING CONDUCTOR

conductor which provides a

conductive path, or part of the

conductive path, between a

given point in a system or in

an installation or in equipment

and an earth electrode

[IEV 195-02-03]](https://image.slidesharecdn.com/earthingandbonding-190616163015/85/Earthing-and-bonding-Power-cables-8-320.jpg)

![Definitions

EARTH ELECTRODE

conductive part, which may be

embedded in a specific

conductive medium, e.g.

concrete, in electric contact

with the earth

[IEV 195-02-01]](https://image.slidesharecdn.com/earthingandbonding-190616163015/85/Earthing-and-bonding-Power-cables-10-320.jpg)

![Definitions

EXTRANEOUS-

CONDUCTIVE-PART

conductive part not forming

part of the electrical

installation and liable to

introduce an electric potential,

generally the electric potential

of a local earth

[IEV 195-06-11]](https://image.slidesharecdn.com/earthingandbonding-190616163015/85/Earthing-and-bonding-Power-cables-11-320.jpg)

![Definitions

PROTECTIVE BONDING

CONDUCTOR

protective conductor provided

for protective-equipotential-

bonding

[IEV 195-02-10]](https://image.slidesharecdn.com/earthingandbonding-190616163015/85/Earthing-and-bonding-Power-cables-12-320.jpg)