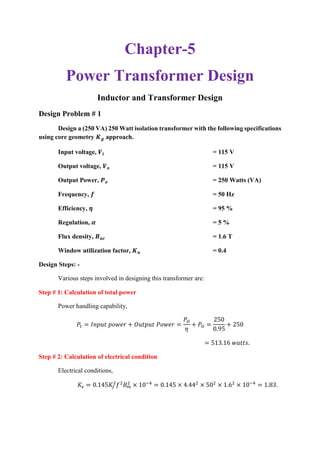

This document provides information on the choice of magnetic cores for inductors and transformers. It discusses different types of core materials including ferrites, powdered iron, and laminated steel. It also covers different core shapes such as EI, UI, C, and toroidal cores. The document provides detailed dimensional data and design considerations for each core type. It discusses factors that influence window utilization in magnetic devices and presents equations for calculating window utilization factor. Finally, it covers topics such as magnet wire, insulation, American wire gauge standards, and formulas for wire diameter calculations.

![Step # 8: Calculation of cross-sectional area (bare) of conductor for primary winding

Bare conductor cross-sectional area,

𝐴 𝑤𝑝(𝐵) =

𝐼 𝑖

𝐽

=

2.288

240.78

= 0.0095 cm2

= 0.95 𝑚𝑚2

.

Step # 9: Selection of wire from wire table

Table 5.3 Table for selecting wire.

The closest Standard Wire Gauge (SWG) corresponding to the bare conductor area

calculated in step # 8 is 18 SWG.

For 18 SWG conductor,

𝐴 𝑤𝑝(𝐵) = 1.17 mm2

.

Resistance for 18 SWG conductor is 14.8

Ω

Km

= 148

𝜇Ω

𝑐𝑚

.

Step # 10: Calculation of primary winding resistance

Resistance of primary winding,

𝑅 𝑝 = 𝑀𝐿𝑇 × 𝑁𝑝 × 148 × 10−6

= 22 × 235 × 148 × 10−6

= 0.765 Ω.

Step # 11: Calculation of copper loss in primary winding

Primary winding copper loss

𝑃𝑝 = 𝐼 𝑝

2

× 𝑅 𝑝 = 2.2882

× 0.765 = 4 Watts.

Step # 12: Calculation of secondary winding turns

Number of turns in the secondary winding

𝑁𝑠 =

𝑁 𝑝×𝑉𝑠

𝑉 𝑖

[1 +

𝛼

100

] =

235×115

115

[1 +

5

100

] = 247.](https://image.slidesharecdn.com/inductorandtransformerdesing-201216155605/85/Inductor-and-transformer-desing-46-320.jpg)