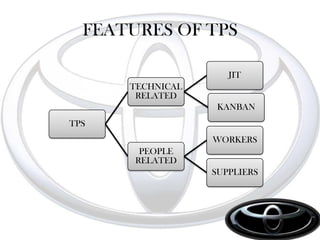

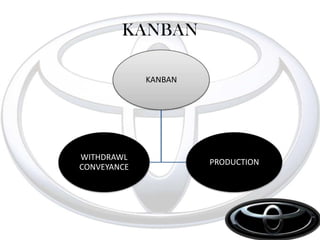

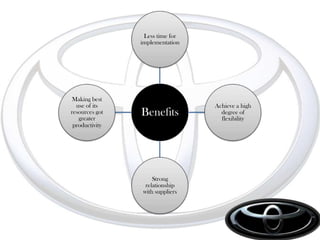

The Toyota Production System (TPS) is Toyota's integrated socio-technical system for managing manufacturing and logistics. Developed since the 1940s, TPS emphasizes just-in-time production, continuous improvement (kaizen), standardized tasks and processes, visual management, and a problem-solving approach to quality issues and waste-reduction. Key elements of TPS include just-in-time production using kanban signals, continuous improvement processes, addressing inefficiencies and waste through kaizen activities, and respect for human factors in the workplace. TPS served as a precursor for modern lean manufacturing techniques.