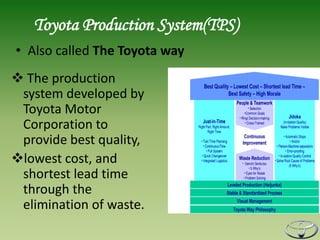

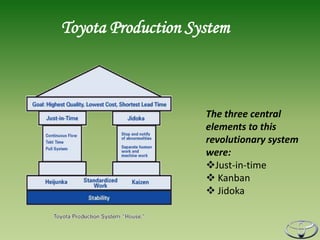

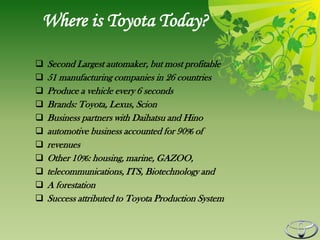

Toyota is the second largest automaker globally but is also the most profitable, with 51 manufacturing companies across 26 countries producing a new vehicle every 6 seconds under its Toyota, Lexus, and Scion brands. Toyota has also diversified its business beyond automotive to include industries like housing, marine, telecommunications, and biotechnology. The company's success is largely attributed to its implementation of the Toyota Production System for efficient manufacturing operations.