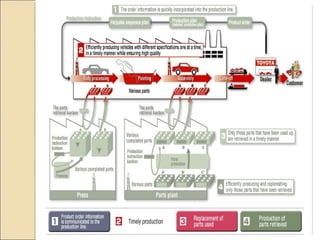

The Toyota Production System (TPS) was developed by Toyota to improve productivity after World War II. [1] Taiichi Ohno drew upon ideas from the West and experimentation to develop TPS between 1948-1975. [2] TPS focuses on just-in-time production, built-in quality control through jidoka, and the elimination of waste through concepts like kanban. [3] The goals of TPS are to design out inconsistency and waste, have flexible production processes, and encourage participation to reduce defects and inventory.