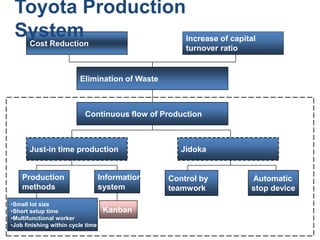

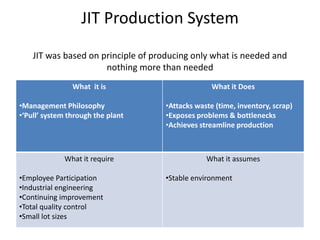

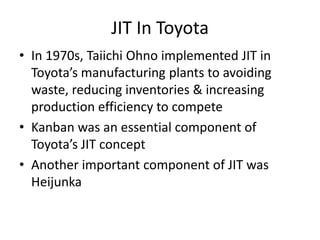

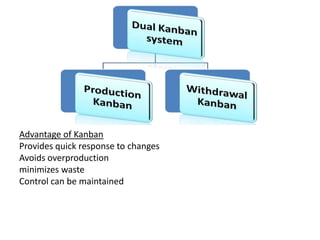

Toyota developed the Toyota Production System (TPS) to eliminate waste through continuous improvement activities and profit through cost reduction. Key aspects of TPS include just-in-time production, which produces only what is needed when it is needed to avoid overproduction, kanban cards that signal the need for more parts, and heijunka level scheduling to smooth production flows. TPS was implemented in the 1970s and helped Toyota compete through avoiding waste, reducing inventories, and increasing production efficiency.