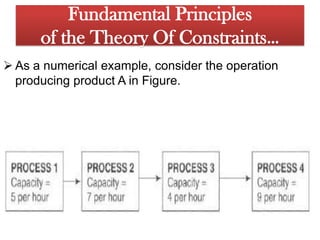

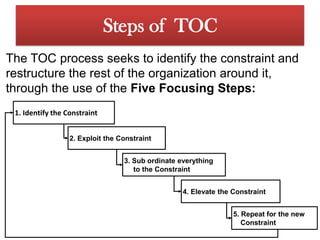

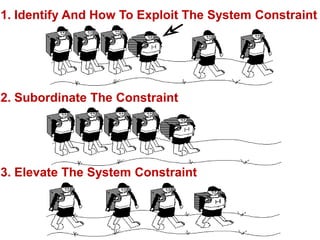

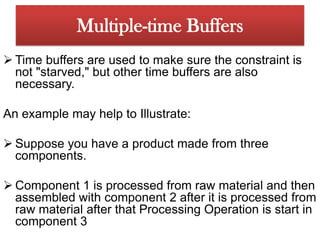

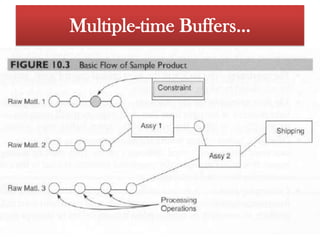

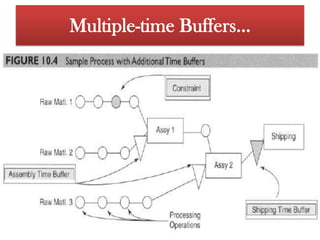

The Theory of Constraints (TOC) is a management philosophy that views an organization as being limited in achieving more of its goals by a very small number of constraints. The core of TOC is that an organization must first identify its constraints, then exploit, subordinate everything else to, elevate, and repeat this process for the next constraint. This involves using buffers, focusing on throughput, operating expenses, and inventory, and making sure constrained resources are never idle and prioritized over non-constrained resources. A real example demonstrated how a medical products plant actively managed constraints by adding capacity or shifting focus to the next constraint.