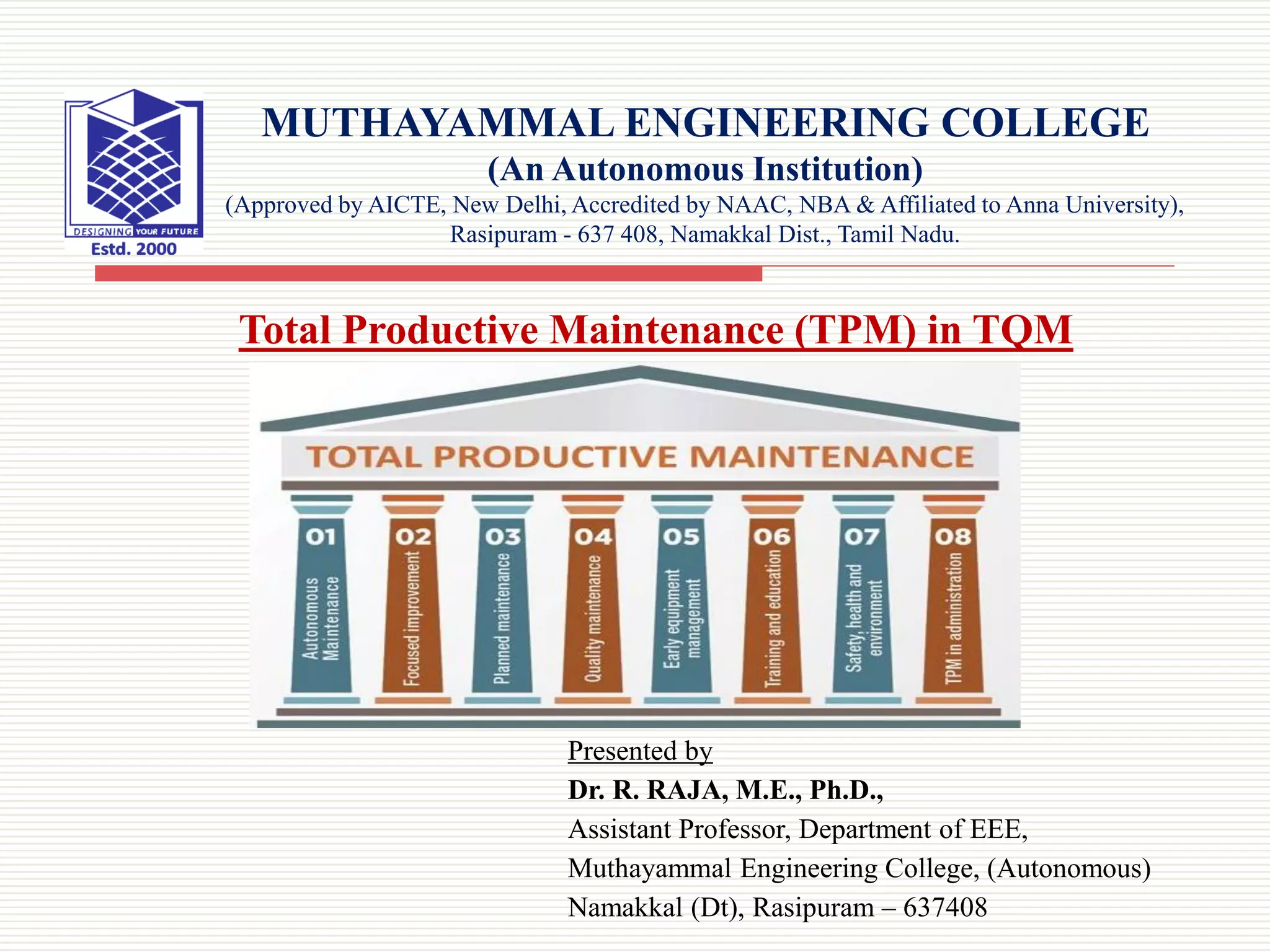

This document discusses Total Productive Maintenance (TPM), which aims to integrate equipment maintenance into manufacturing processes to improve productivity and asset availability. TPM emerged from the need to move from reactive to preventative maintenance through predictive maintenance. The goal of TPM is to ensure machinery is always available to manufacture products with minimal rework and downtime. Successful TPM requires cross-functional teamwork and employee involvement in routine maintenance. Metrics like Overall Equipment Effectiveness are used to measure TPM success and identify improvement areas. Companies implementing TPM see decreased maintenance costs, increased equipment uptime and profitability, and improved teamwork.