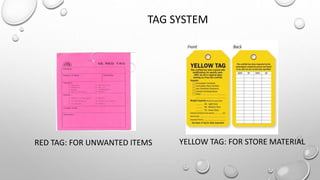

This document provides an overview of 5S training and awareness. It describes the history and objectives of 5S, which is a structured program for implementing workplace organization and standardization. The 5S methodology represents 5 disciplines - Sort, Set In Order, Shine, Standardize, and Sustain. Examples are given for each discipline, as well as how to create a visual workplace and the benefits of practicing 5S, such as improved productivity, quality, and safety.