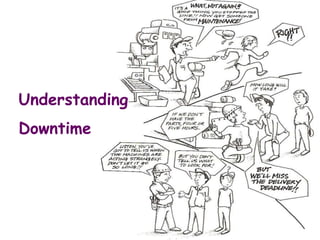

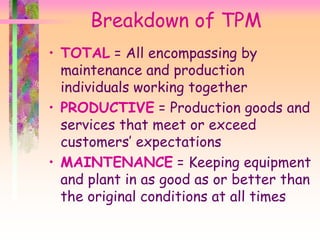

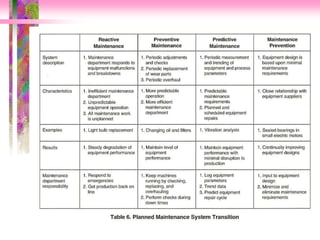

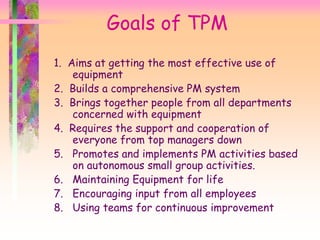

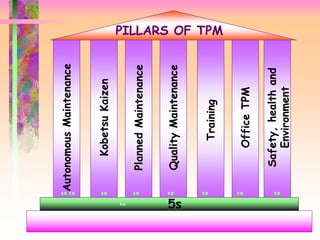

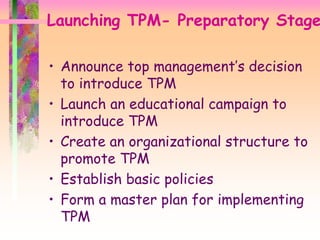

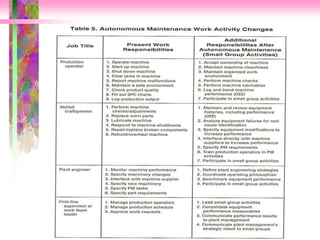

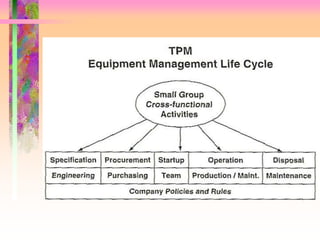

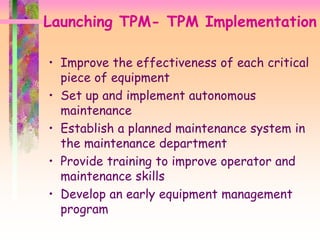

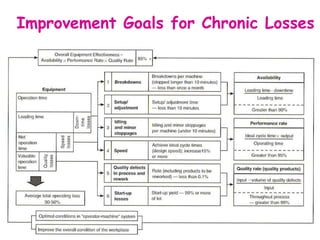

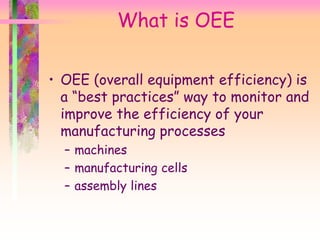

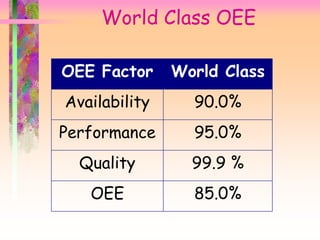

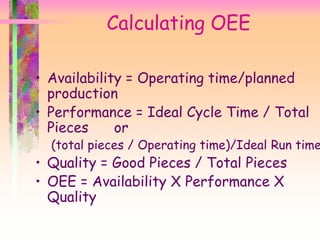

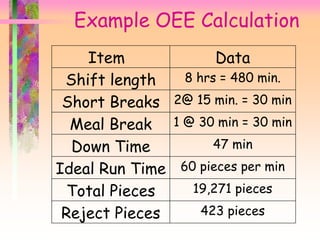

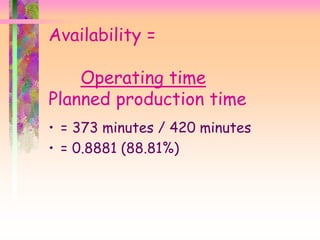

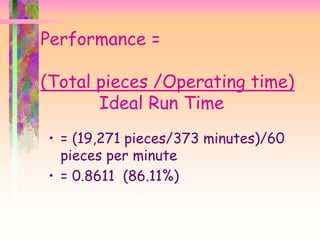

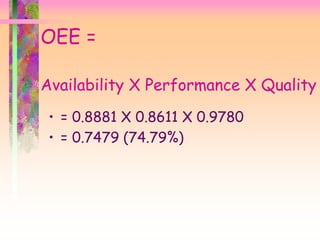

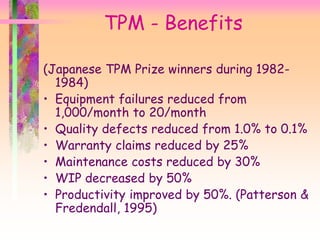

The document outlines the agenda and topics for a meeting on Total Productive Maintenance (TPM). The agenda covers understanding downtime, major losses, an introduction to TPM including its history and goals, launching a TPM program through various stages, and overall equipment efficiency (OEE). Specific managers are assigned to lead discussions on sub-topics such as planned vs unplanned downtime, the eight pillars of TPM, and calculating OEE. The overall goal of the meeting is to introduce an approach for continuous equipment improvement using TPM.