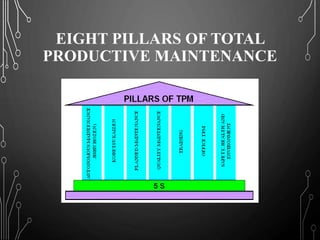

Total Productive Maintenance (TPM) is a plant improvement methodology focused on continuous manufacturing process improvement through employee involvement and empowerment. It aims to reduce waste, maintain product quality, and lower costs while enhancing productivity and customer satisfaction. With roots in Japan from the 1970s, TPM now sees widespread implementation globally, benefiting companies through improved plant reliability and employee ownership of equipment.