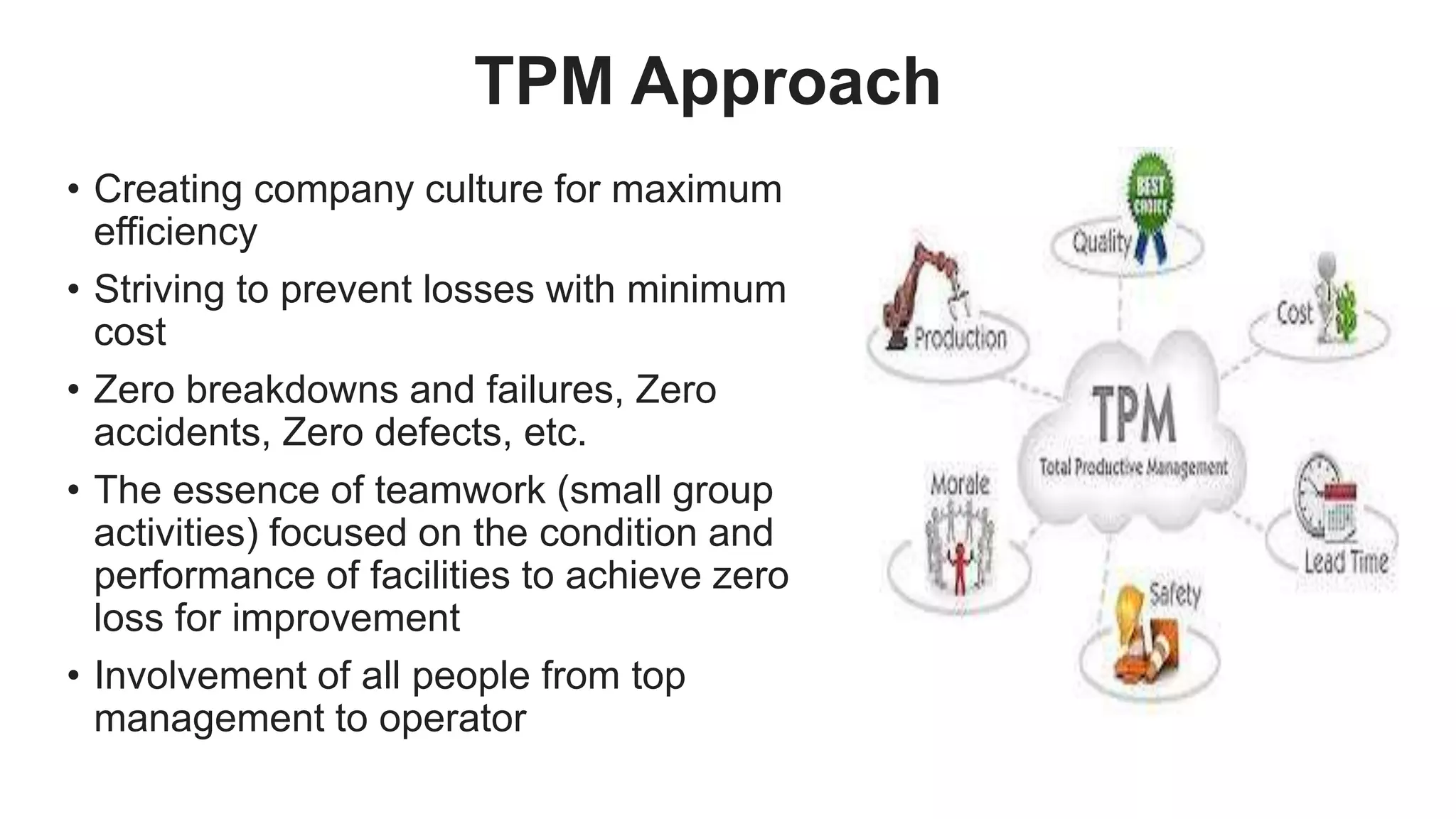

TPM aims to maximize equipment effectiveness through total employee involvement and proactive maintenance to improve reliability and productivity. TPM emphasizes preventing breakdowns and losses by increasing overall equipment effectiveness. It has eight pillars that include autonomous maintenance, preventative maintenance, education and training, and safety. TPM creates a company culture of maximum efficiency by striving to prevent losses with minimum cost through teamwork and involvement from all levels to achieve zero losses and continuous improvement.