This document provides design considerations for powder metallurgy parts. Key points include:

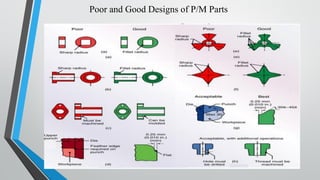

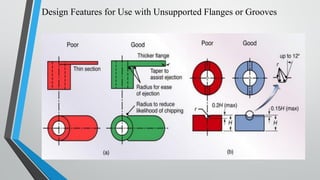

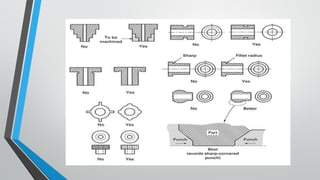

- Part shapes should be simple and uniform to allow for easy ejection from the die without damage.

- Tolerances and wall thicknesses are limited, with minimum wall thickness of 1.5mm.

- Simple steps and perpendicular letters can be included but must be carefully designed.

- Radii cannot be pressed directly, chamfers must be used instead.

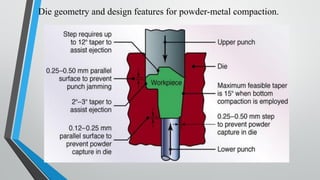

- Die design must create strong tooling that can withstand pressing forces of 700MPa.