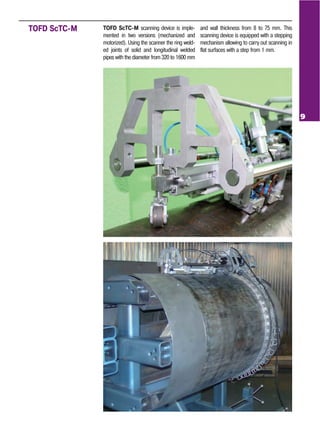

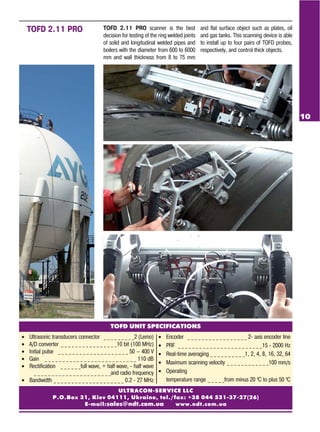

The TOFD Pro System is designed for non-destructive testing of welded joints using the Time of Flight Diffraction (TOFD) technique, complying with various standards. It can test a variety of configurations including flat objects, medium to large diameter tubes, and various types of welds, offering high sensitivity in defect detection and characterization. The system includes advanced software for setup, data acquisition, and analysis, facilitating efficient and accurate testing processes.