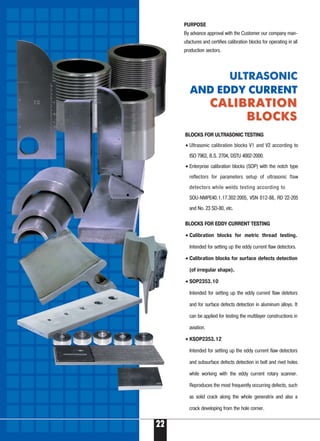

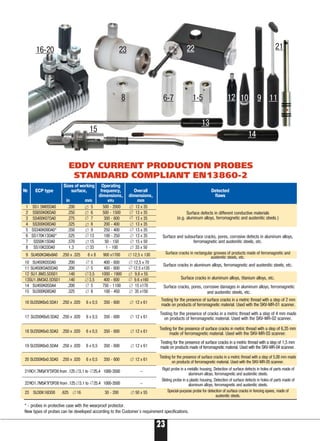

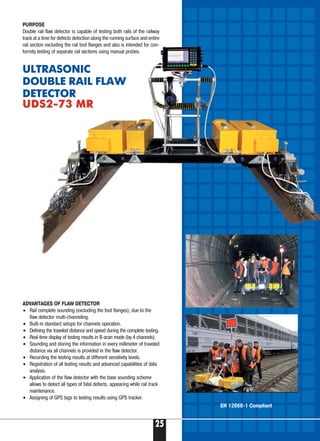

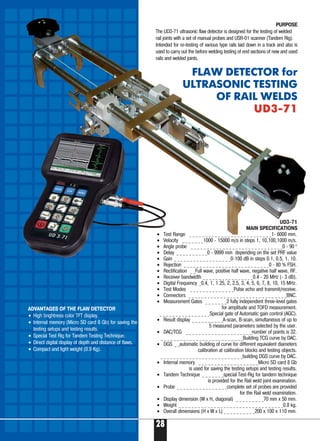

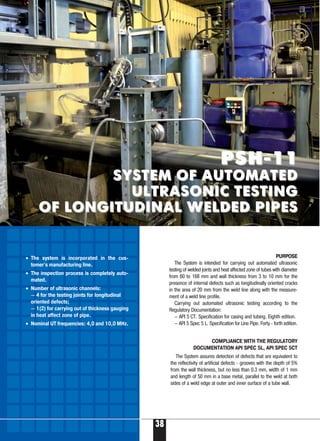

The document describes the OKO Association, which brings together several Ukrainian companies that provide non-destructive testing (NDT) technologies and services. The Association aims to solve all problems related to NDT using a full range of equipment and techniques. It offers ultrasonic, eddy current, visual, penetrant, magnetic particle, and acoustic emission testing methods. The Association's members are leaders in NDT equipment for the domestic market and can also design customized automated NDT systems. The Association provides training and certification for NDT personnel.