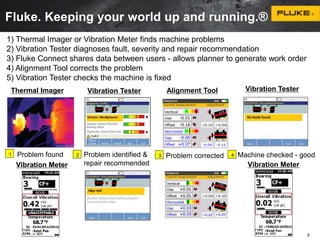

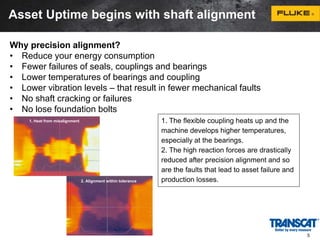

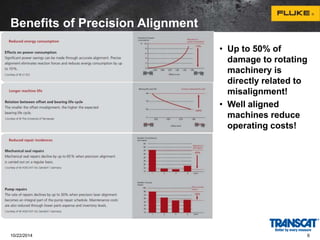

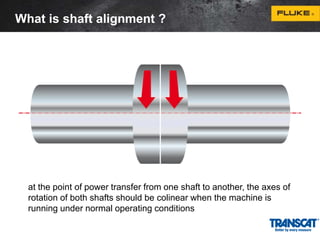

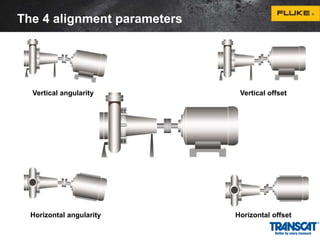

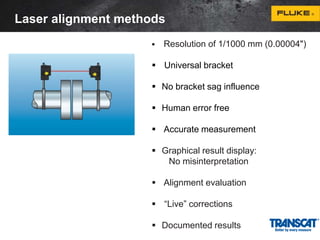

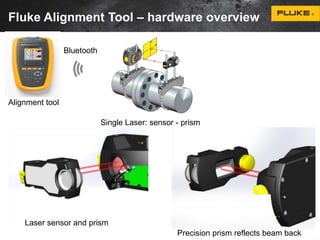

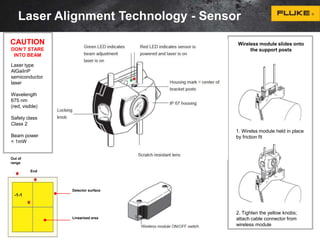

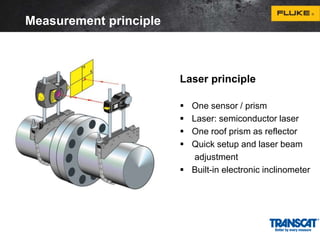

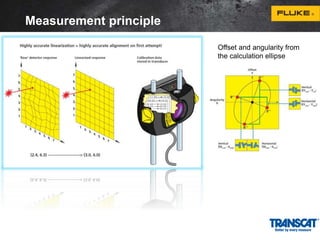

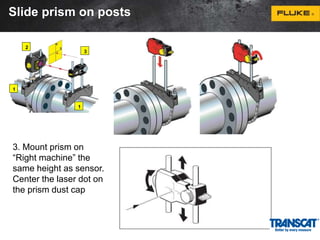

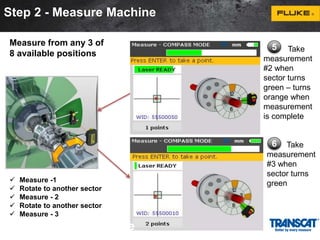

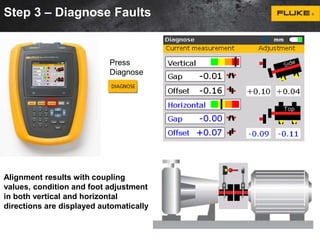

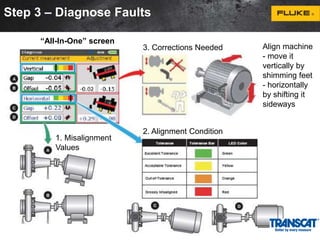

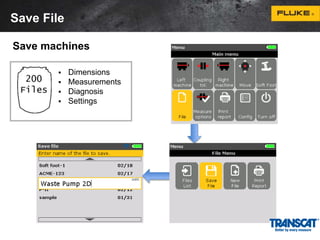

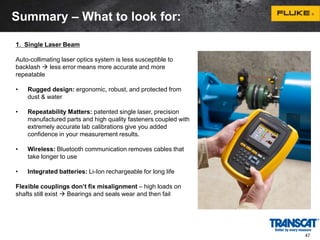

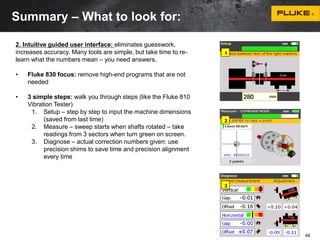

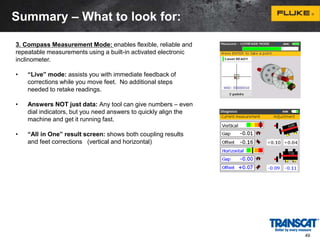

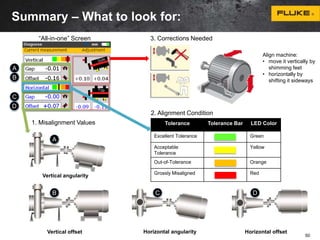

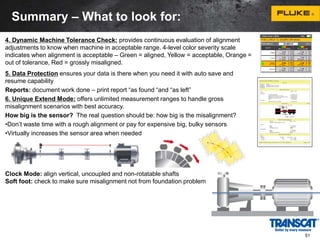

The document discusses precision laser shaft alignment using the Fluke 830 Laser Alignment tool. It provides an overview of the benefits of precision alignment, describes laser alignment principles and the Fluke tool. The Fluke tool allows for quick, easy, and precise alignment in 3 steps: setup, measurement, and diagnosis/correction. It provides intuitive guidance and diagnostic information to correctly align shafts and maximize machine reliability and uptime.