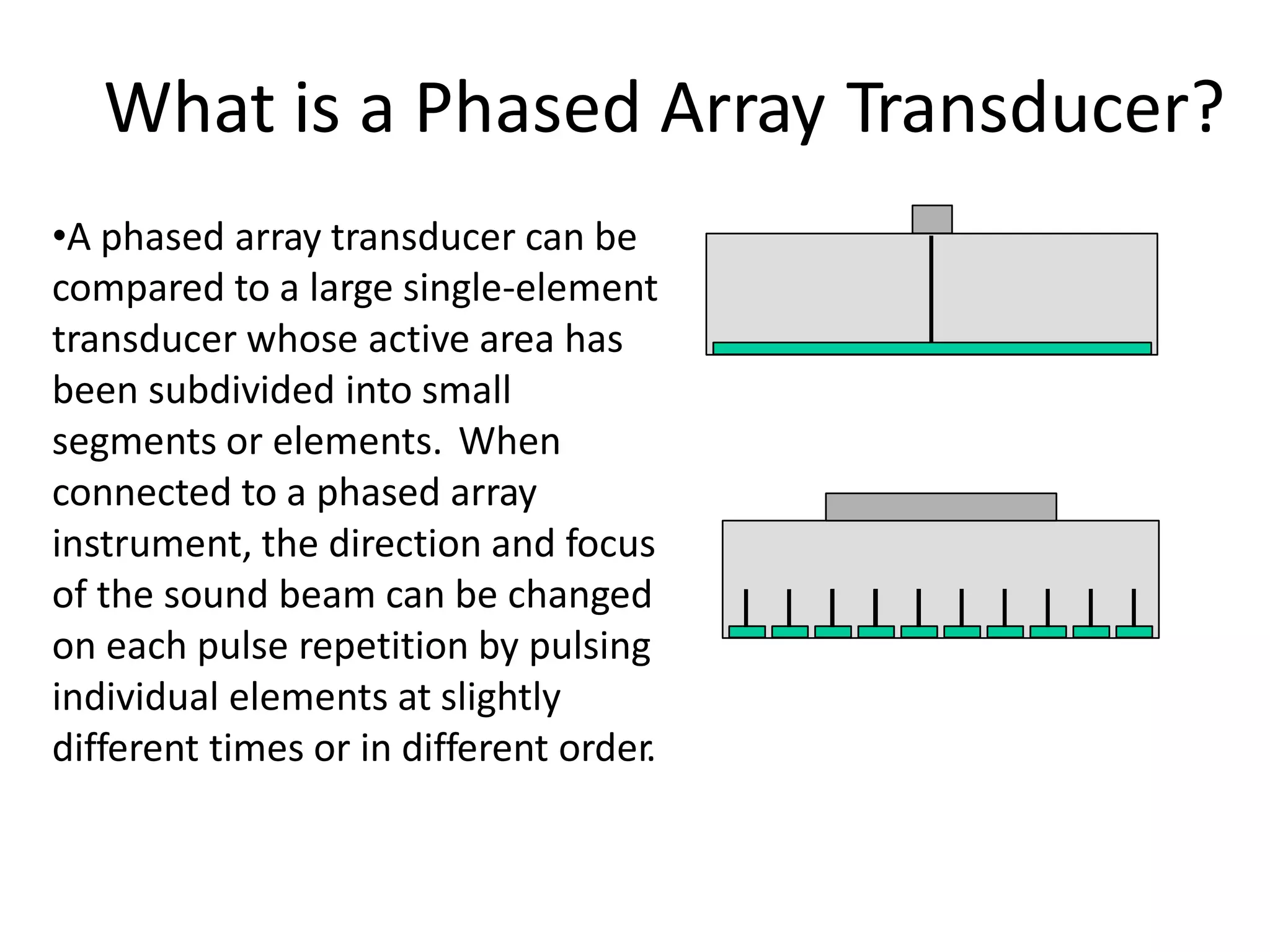

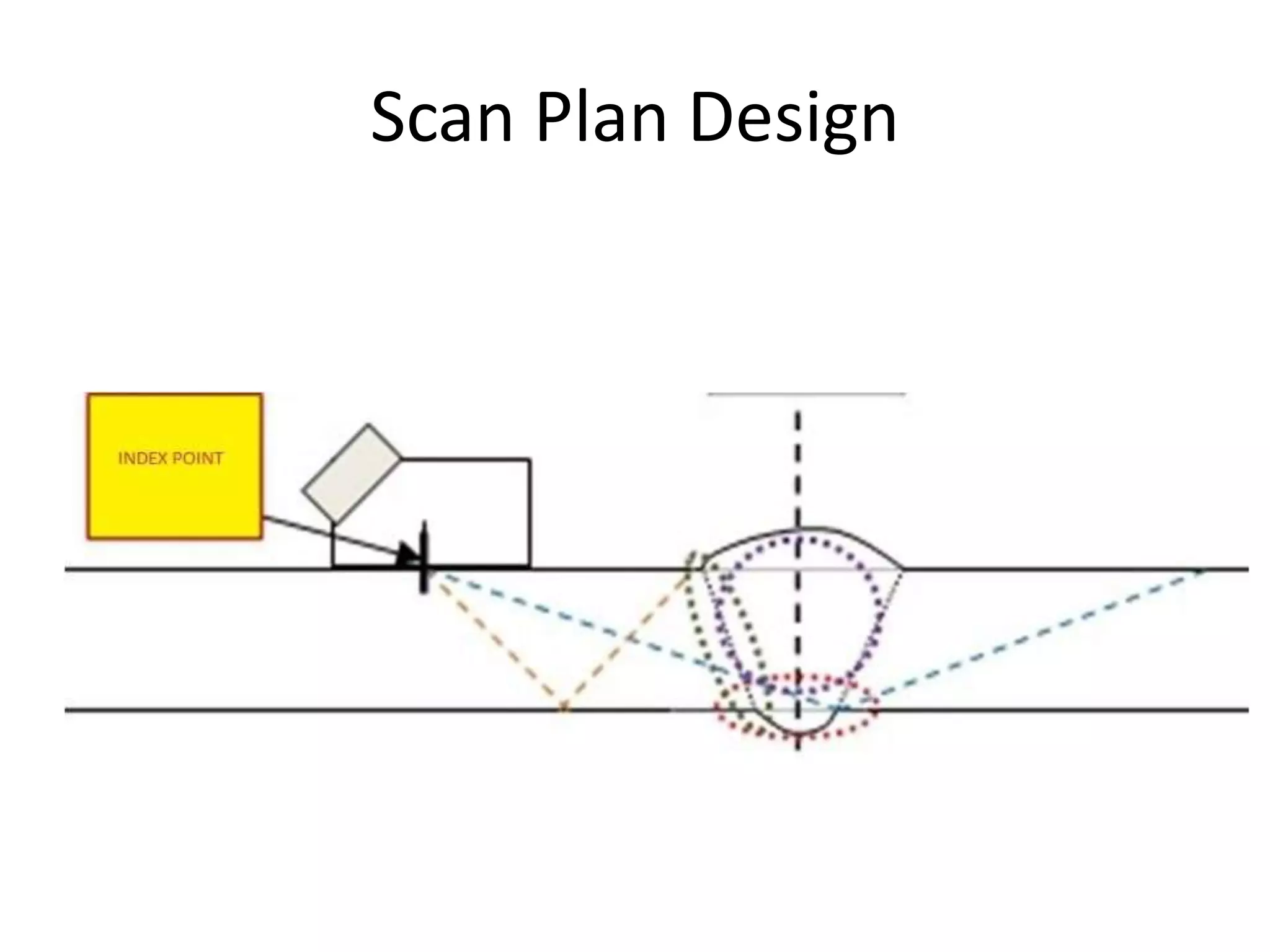

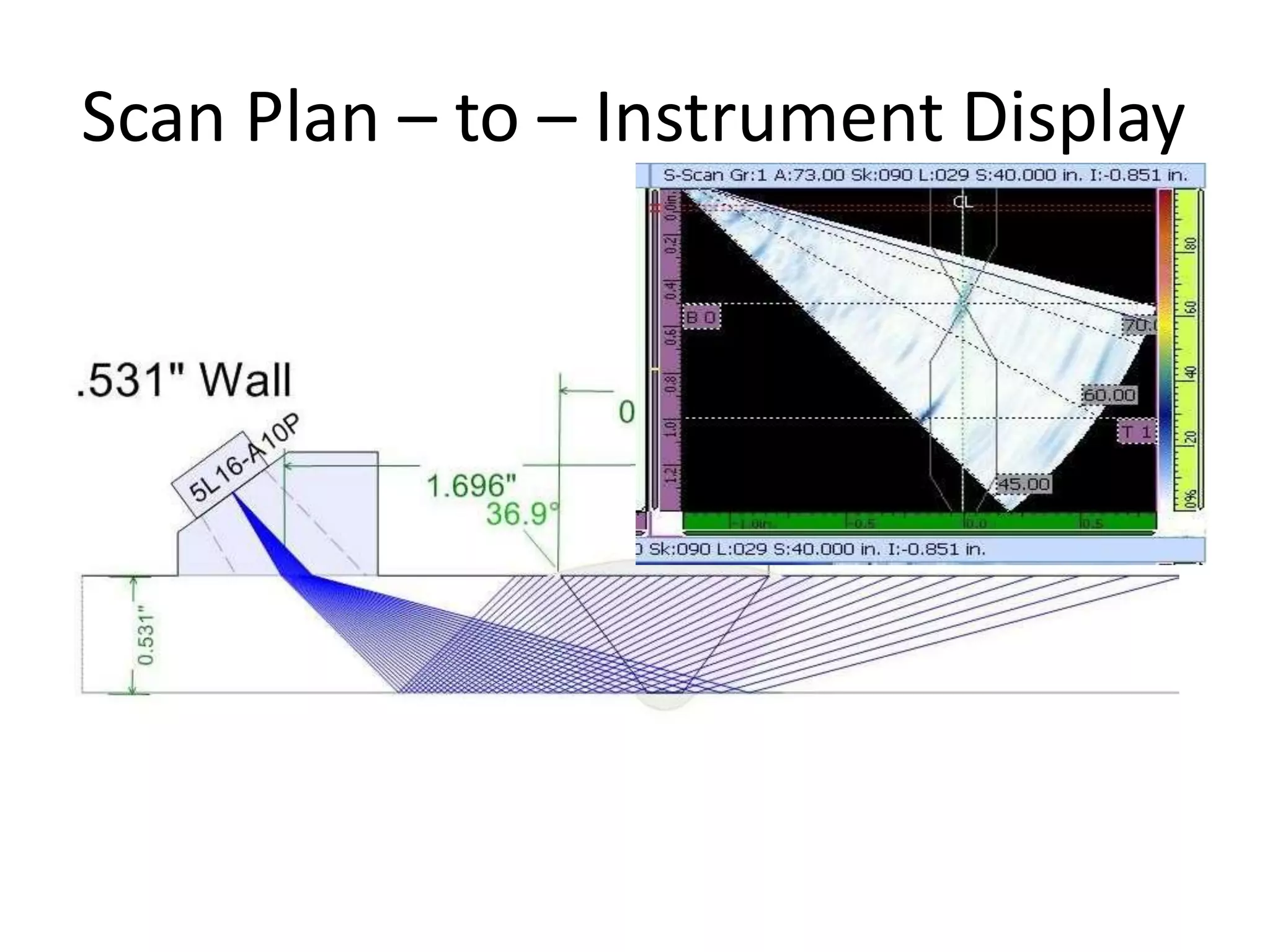

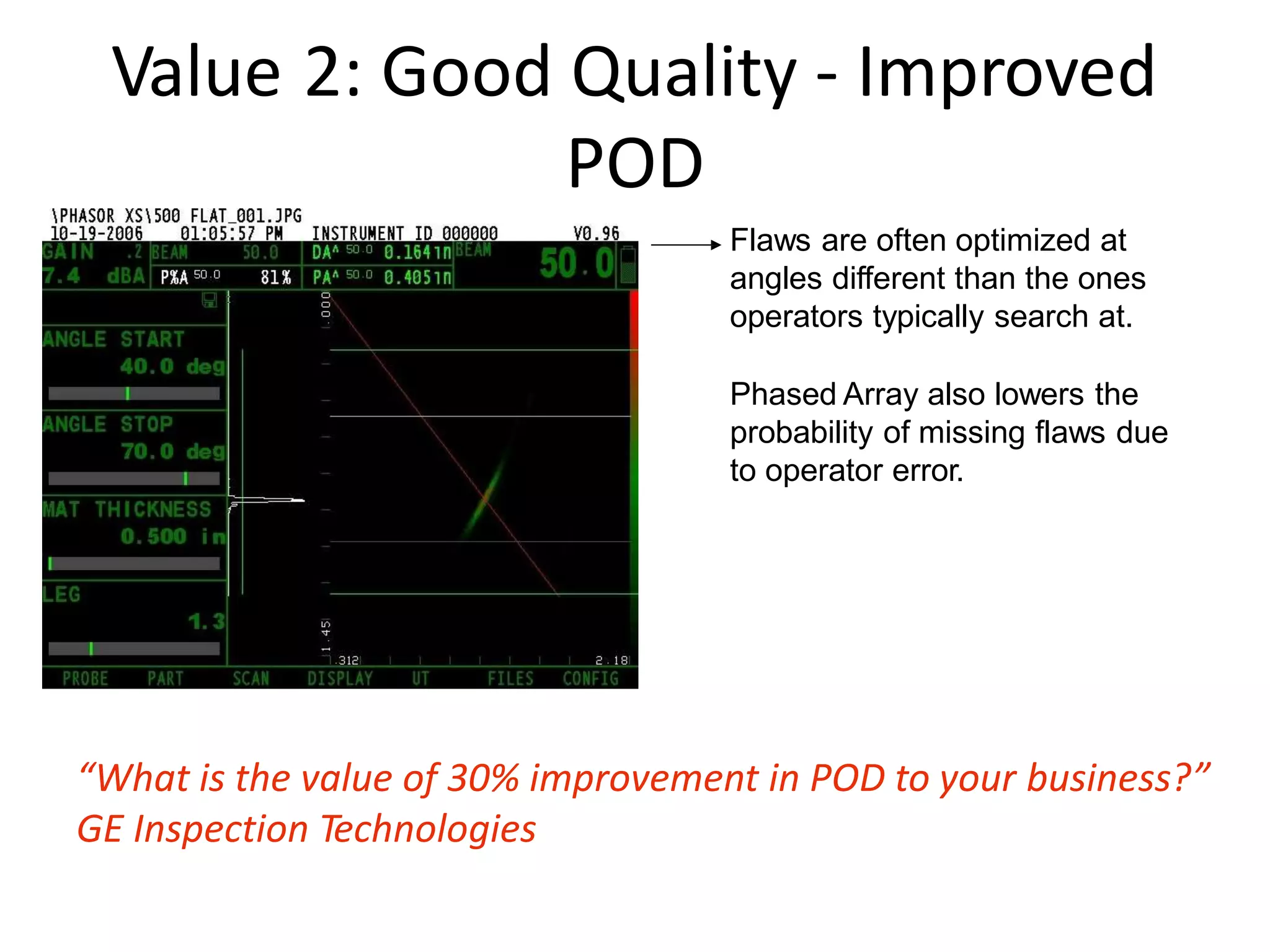

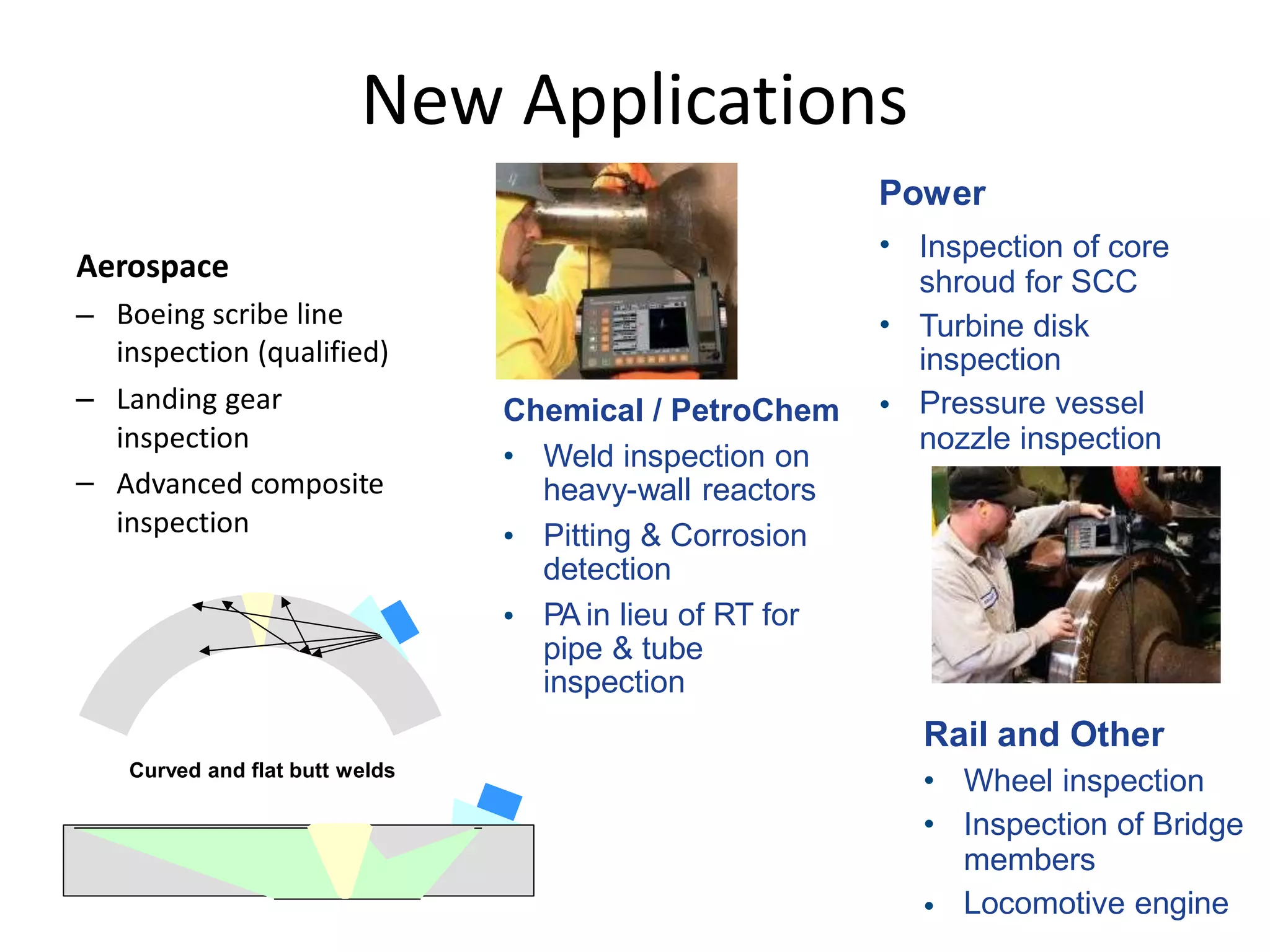

This document discusses the benefits and applications of phased array ultrasonic testing (PAUT) weld inspection. It describes how PAUT uses multiple independently controlled transducer elements to focus and steer ultrasound beams, providing improved detection, characterization and sizing of weld defects compared to conventional UT. Key benefits outlined include 30% improved probability of detection, 40% improved sizing precision, 20% faster inspections, real-time results, and expanded inspection capabilities with fewer limitations and hazards compared to radiography. PAUT is increasingly used for inspections in power, chemical, aerospace and other industries.