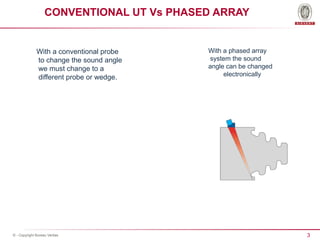

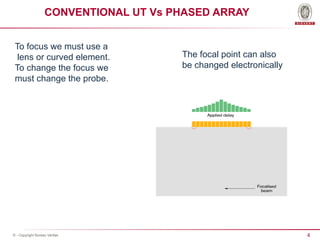

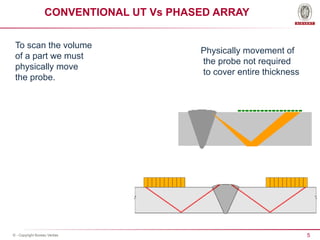

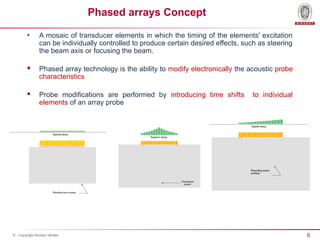

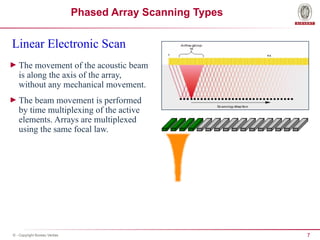

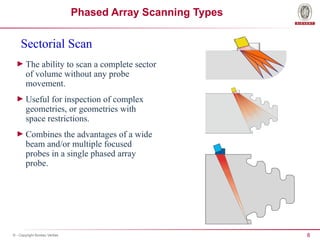

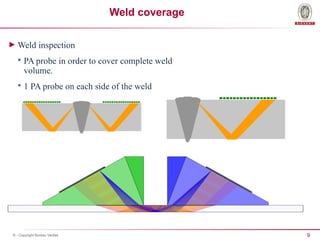

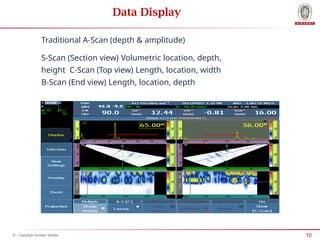

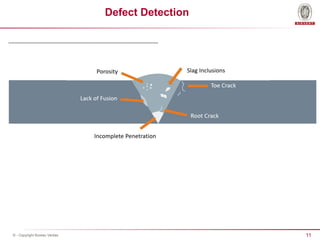

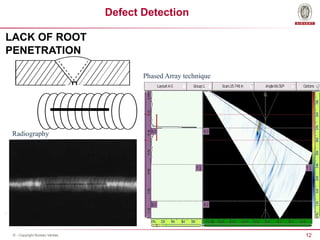

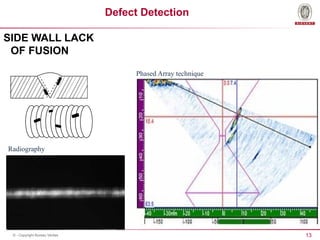

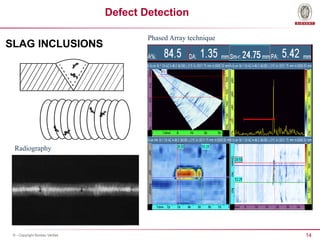

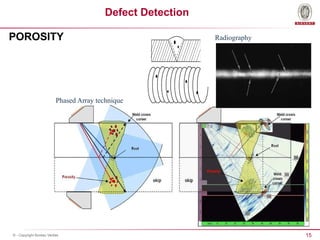

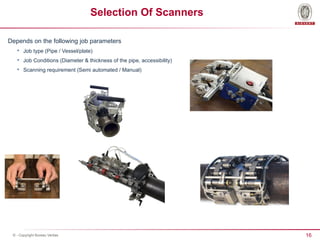

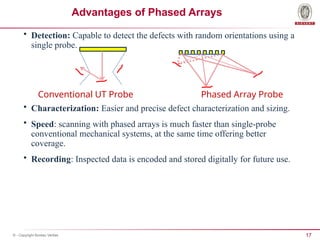

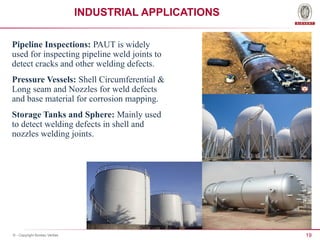

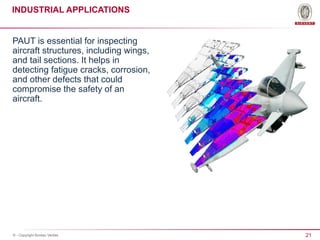

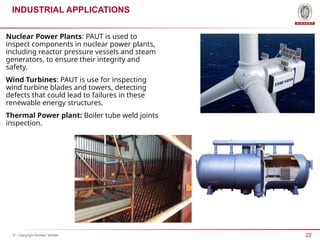

This document discusses phased array ultrasonic testing (PAUT) technology, highlighting its advantages over conventional ultrasonic testing (UT), such as electronic control of sound angles and faster scanning capabilities. It describes various scanning types, defect detection methods, and specific industrial applications including pipeline inspections and aircraft structure evaluations. The document also outlines job requirements and conditions necessary for effective PAUT implementation.