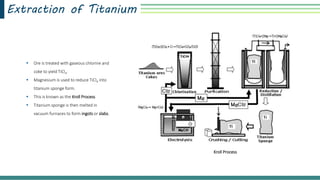

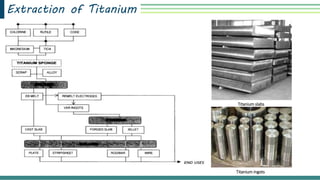

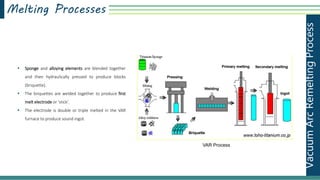

This document provides an overview of titanium, including its physical properties, production process, uses as a building material, and examples of architectural applications. Titanium is a strong yet lightweight transition metal that is extracted from ores through a chlorine process and then purified. It has high strength, corrosion resistance, and is lighter than steel. Some key uses of titanium in architecture include cladding for buildings, structures like stadiums and theaters, and applications where corrosion resistance is important like chemical plants. It can be formed and fabricated into parts for its aesthetic and durable properties in construction.