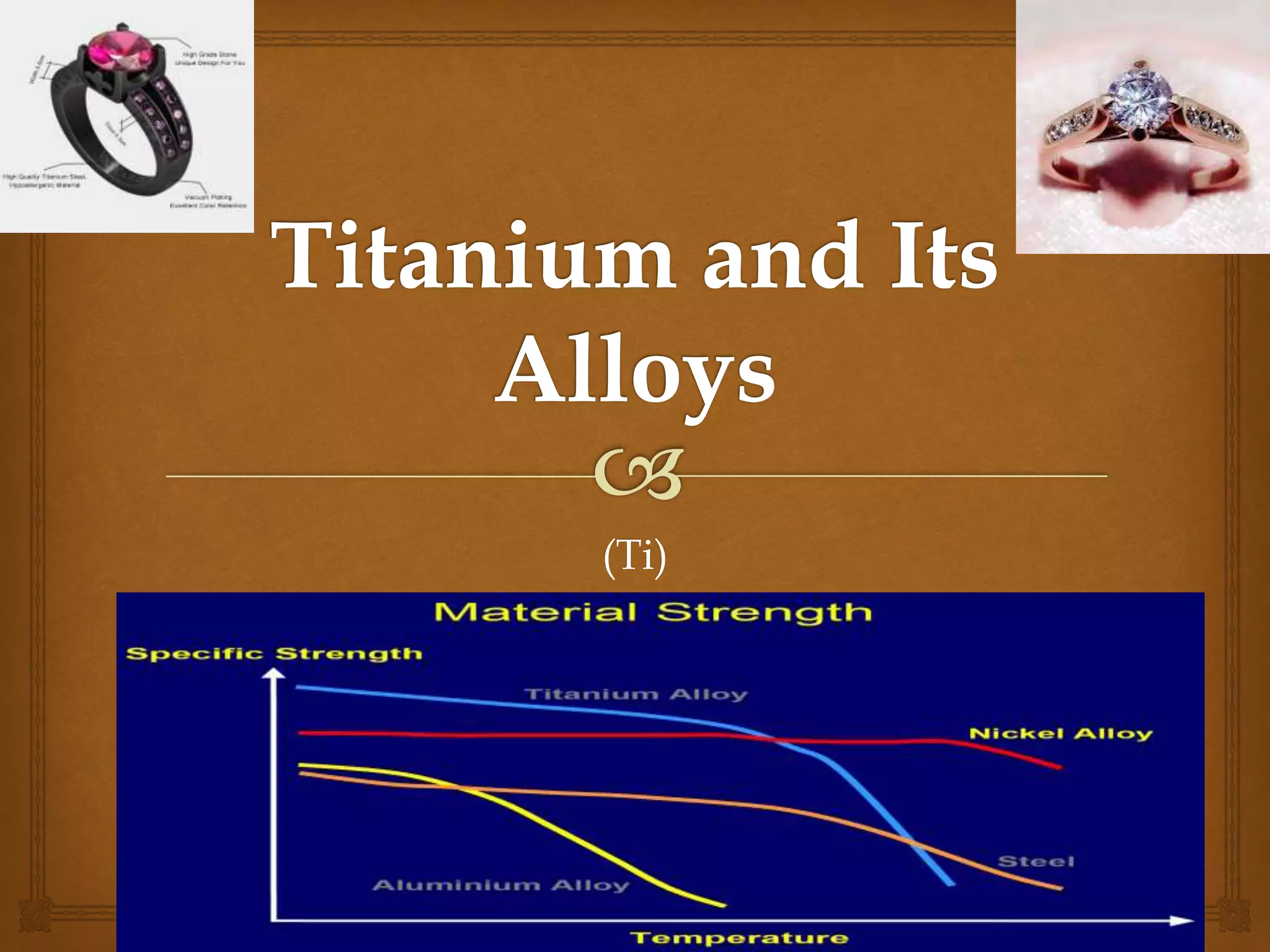

Titanium is a lustrous transition metal with low density and high strength. It is produced commercially from titanium dioxide via the Kroll process. Titanium has excellent corrosion resistance and high strength at elevated temperatures, making it useful for applications in aerospace, marine, chemical and biomedical industries. It exists in two crystal structures, hexagonal close-packed at lower temperatures and body-centered cubic at higher temperatures, and can be alloyed to modify its properties for different applications.