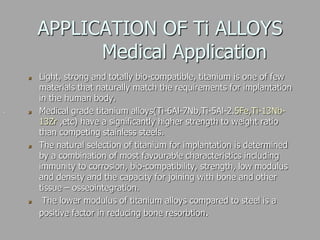

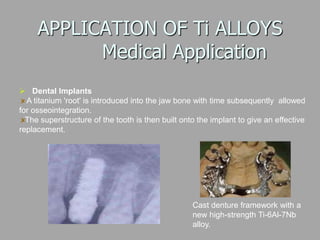

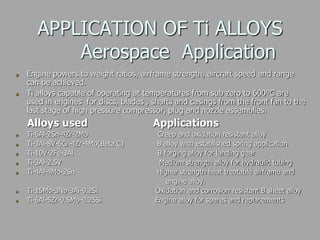

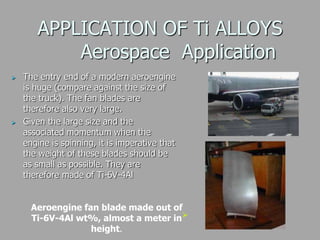

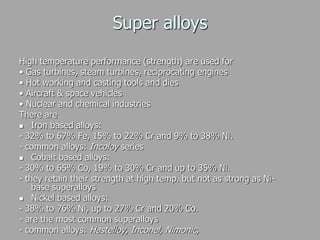

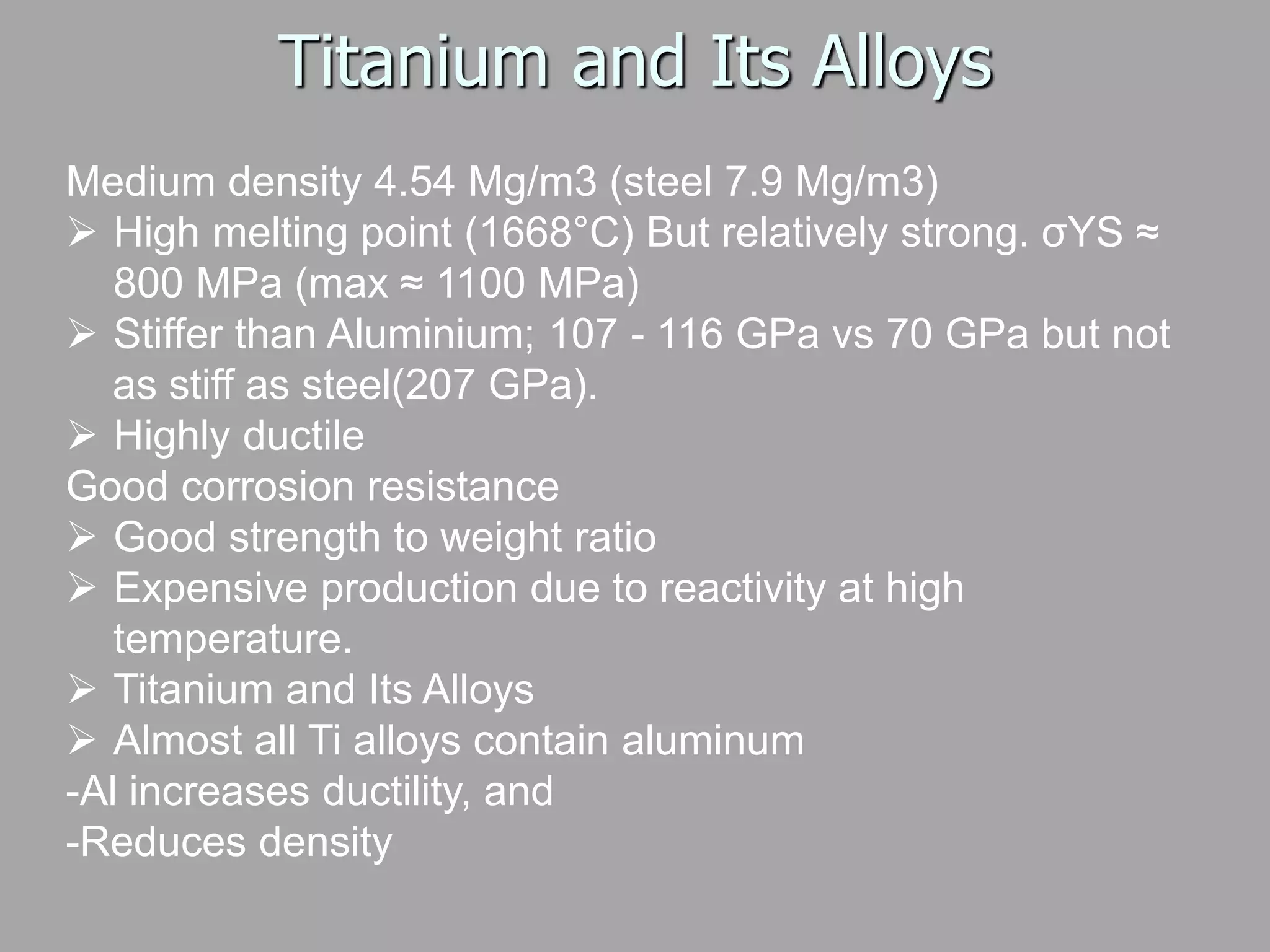

Titanium and its alloys have several desirable properties including high strength to weight ratio, corrosion resistance, and biocompatibility. Common titanium alloys contain aluminum and vanadium. Titanium is used widely in aerospace applications due to its high strength and low density, as well as in medical implants and devices where it is compatible with the human body. However, titanium is expensive to produce due to its high reactivity at high temperatures requiring specialized production techniques.

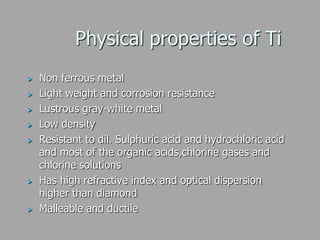

![ Titanium and its alloys are relatively new engineering materials that

possess an extraordinary combination of properties.

The pure metal has a relatively low density (4.5 g/cm3), a high melting

point [1668C], and an elastic modulus of 107 GPa ( psi).

Titanium alloys are extremely strong; room temperature

tensile strengths as high as 1400 MPa (200,000 psi) are attainable,

yielding remarkable specific strengths.

Furthermore, the alloys are highly ductile and easily forged

and machined.](https://image.slidesharecdn.com/nonferroustini-201006110442/85/Non-ferrous-ti-ni-3-320.jpg)

![Ti

Atomic symbol : Ti

Atomic weight : 47.90

Electron configuration : [Ar] 4s

Atomic radius : 144.5

Melting point : 1668 C

Boiling point : 3287 C

Oxidation state : 4,3,2](https://image.slidesharecdn.com/nonferroustini-201006110442/85/Non-ferrous-ti-ni-5-320.jpg)