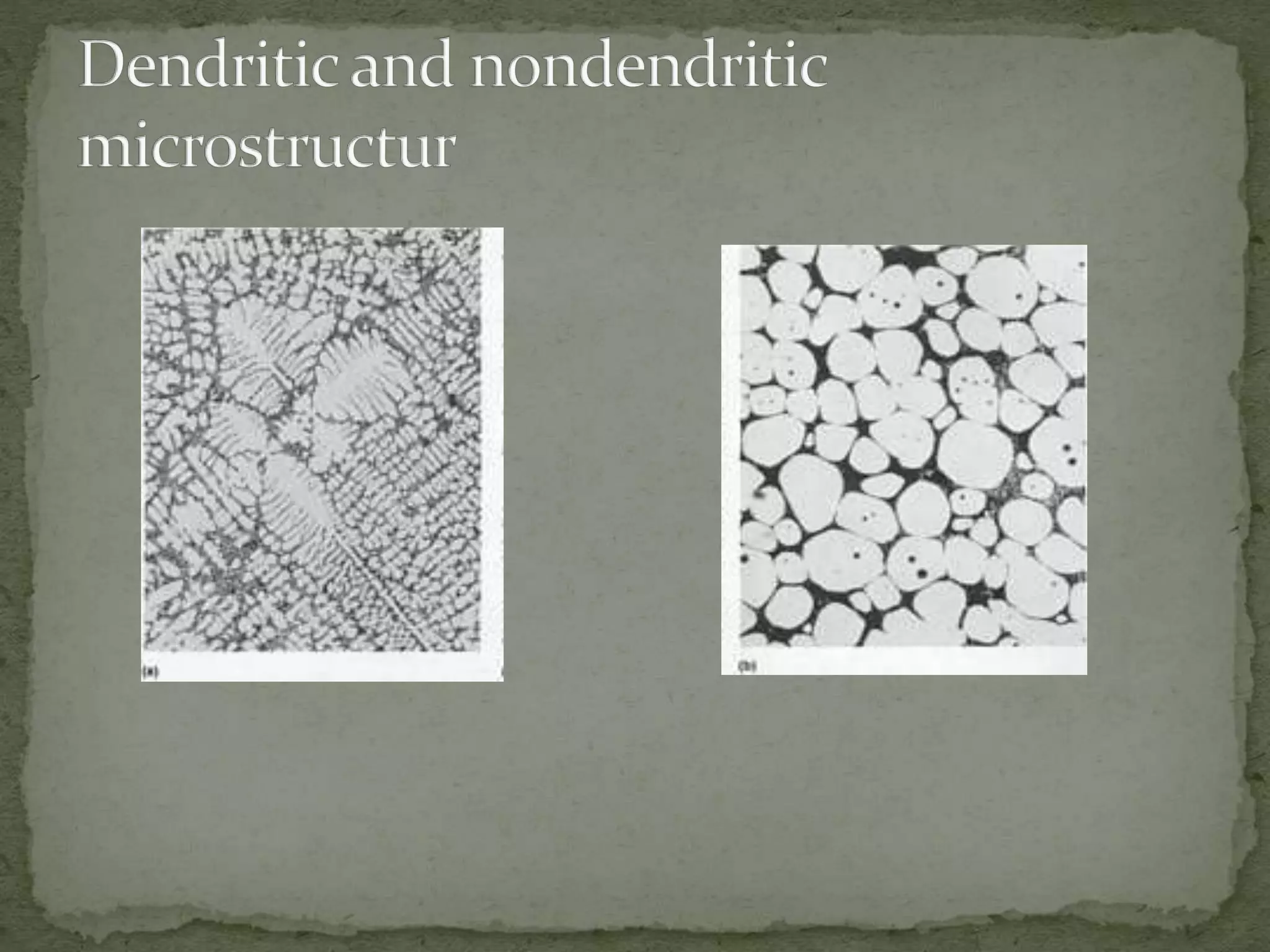

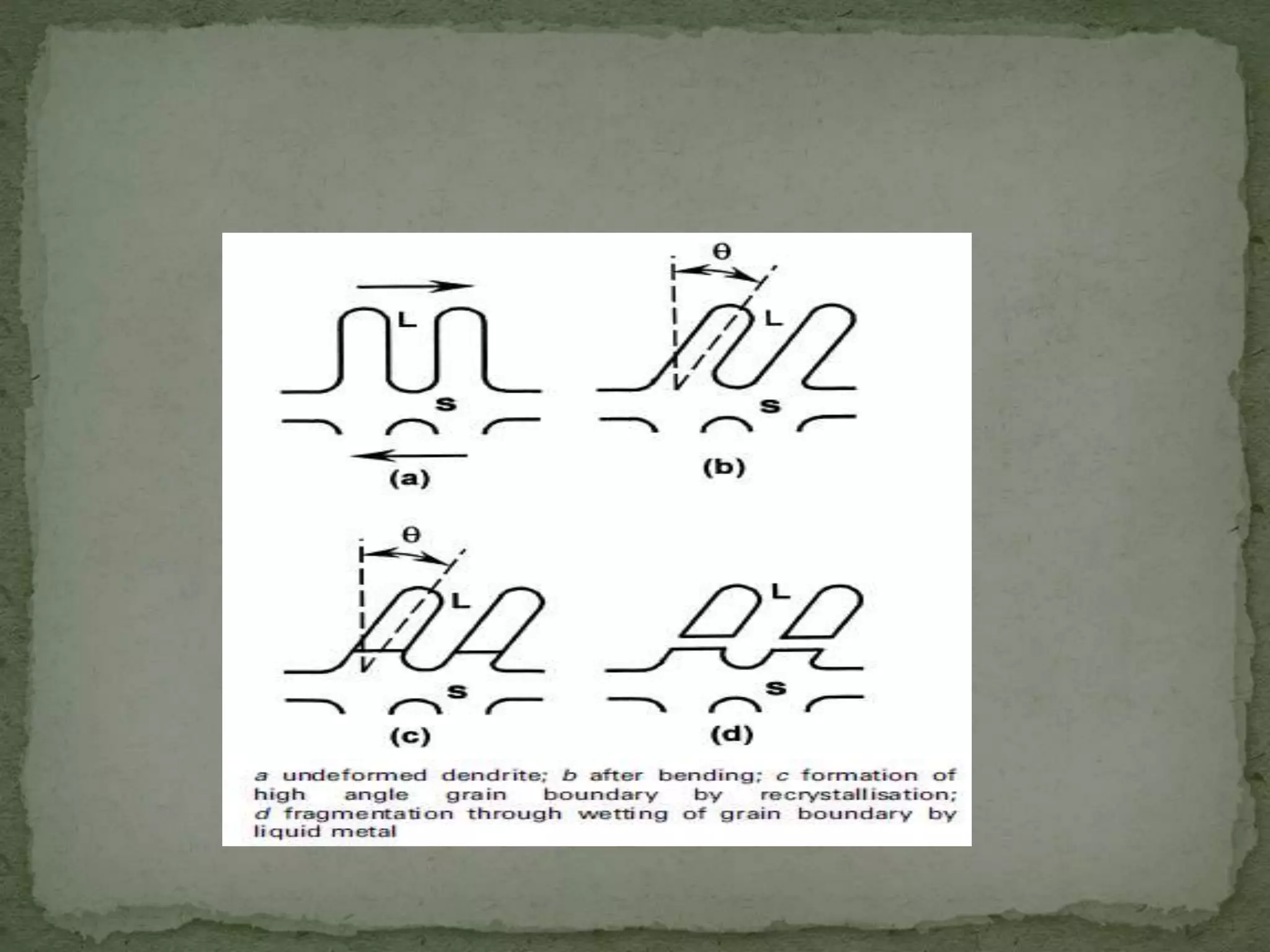

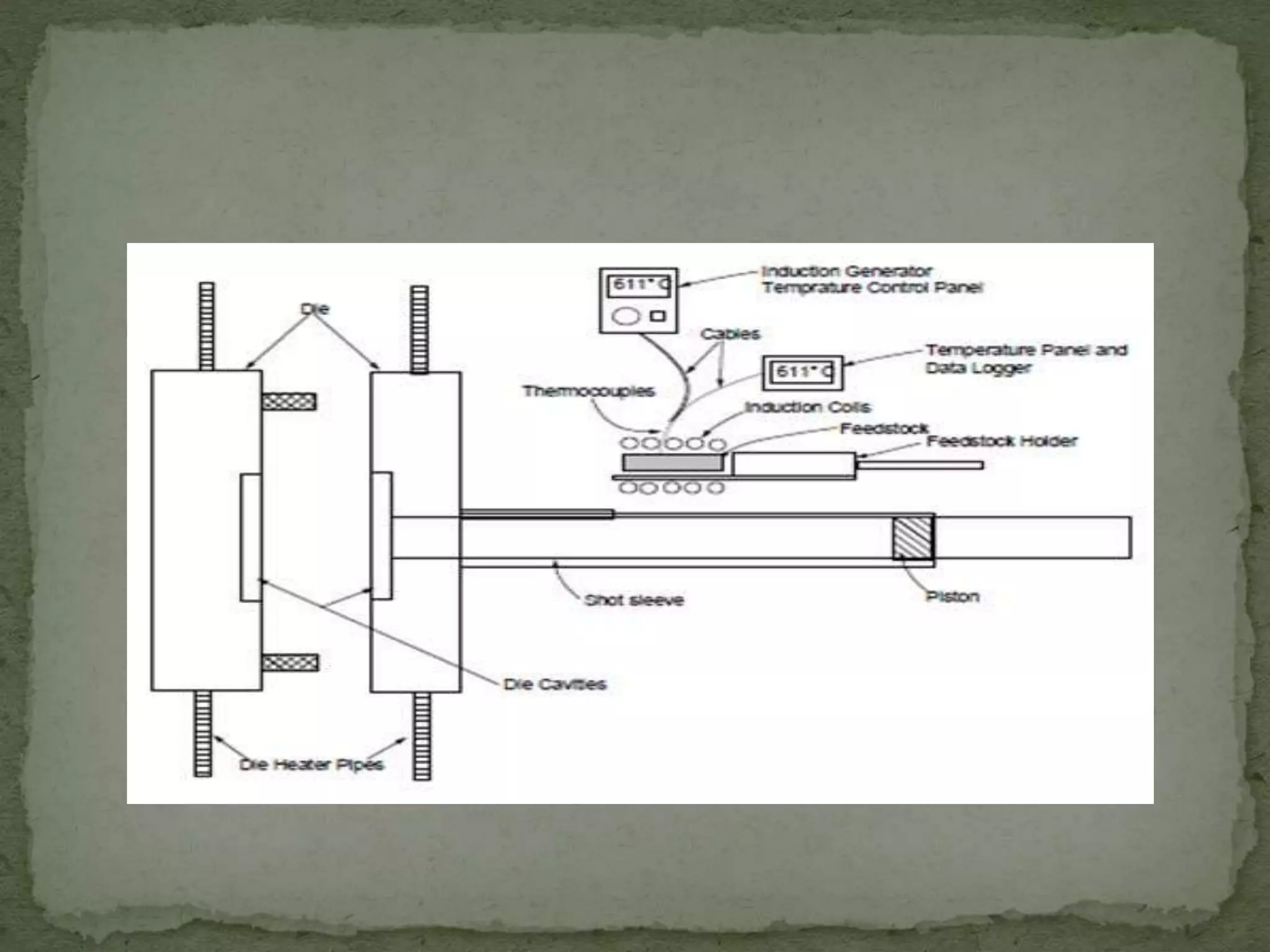

The document discusses the discovery of semisolid metal processing at MIT in 1970 during research on hot tears in lead-tin alloys molded in an annular space between two concentric cylinders. When the outer cylinder was rotated, the semisolid alloy exhibited low shear strength even at high fractions of solidification, resulting in a novel nondendritic microstructure. Semisolid alloys were found to display thixotropic properties, with viscosity dependent on shear rate ranging from hundreds to thousands of poise at rest to less than 50 poise during agitation, allowing control of alloy viscosity.