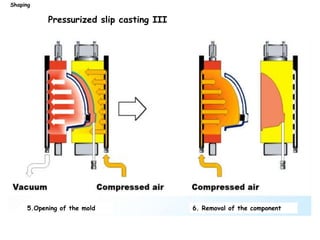

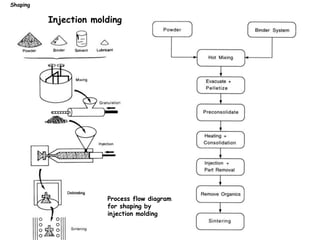

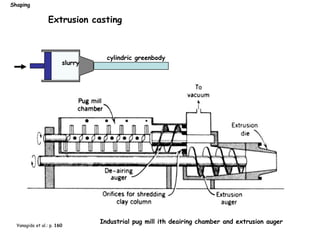

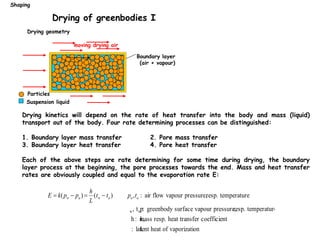

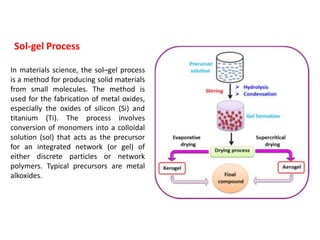

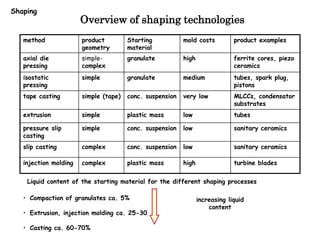

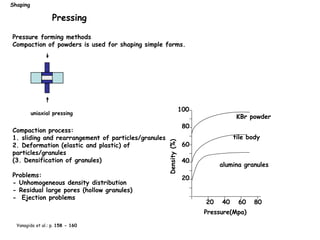

The document discusses various processing methods for ceramics, including the sol-gel process, slip casting, tape casting, extrusion, injection molding, and drying of green bodies. The sol-gel process involves the conversion of monomers into a colloidal solution that acts as a precursor for an integrated network or gel. Slip casting involves pouring a slurry into a plaster mold where the liquid is absorbed, depositing powder particles. Tape casting uses a doctor blade to spread a slurry onto a film at controlled thickness. Drying of green bodies occurs through boundary layer and pore processes, with shrinkage and defects occurring if not done uniformly.

![A doctor blade assembly. The ceramic

slurry is held in the reservoir behind

the blade [middle of the micrograph].

The twin micrometers [right] control the

blade height above the carrier film.

More sophisticated versions feature

double blades and pumped metered

slurry flow to keep the height of the

slurry reservoir constant.

Example of a tape drying on the Mistler

laboratory-scale batch tape caster.

Industrially the process is often continuous

with the tape being force dried prior to

removal from the carrier, dicing and

further processing.

Tape casting II

Shaping](https://image.slidesharecdn.com/07-8-lectureprocessing-211110120110/85/07-8-lecture-processing-25-320.jpg)