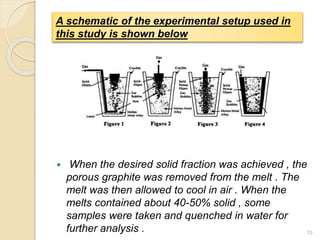

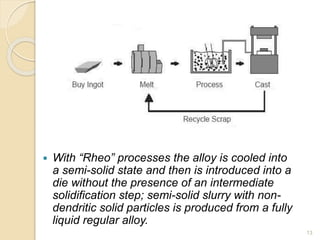

This seminar report summarizes a study on rheocasting. It defines rheocasting as a process that creates a semi-solid slurry directly from molten metal and pushes it into a mold to freeze, unlike thixocasting which reheats a billet. The report outlines the key steps in rheocasting including slurry generation techniques like stirring, dendrite fragmentation, and pressure waves. It discusses benefits like lower casting pressures/temperatures and disadvantages like needing precise control. In conclusion, the report notes potential applications for rheocasting include replacing permanent molds and producing high-strength or wear-resistant parts.