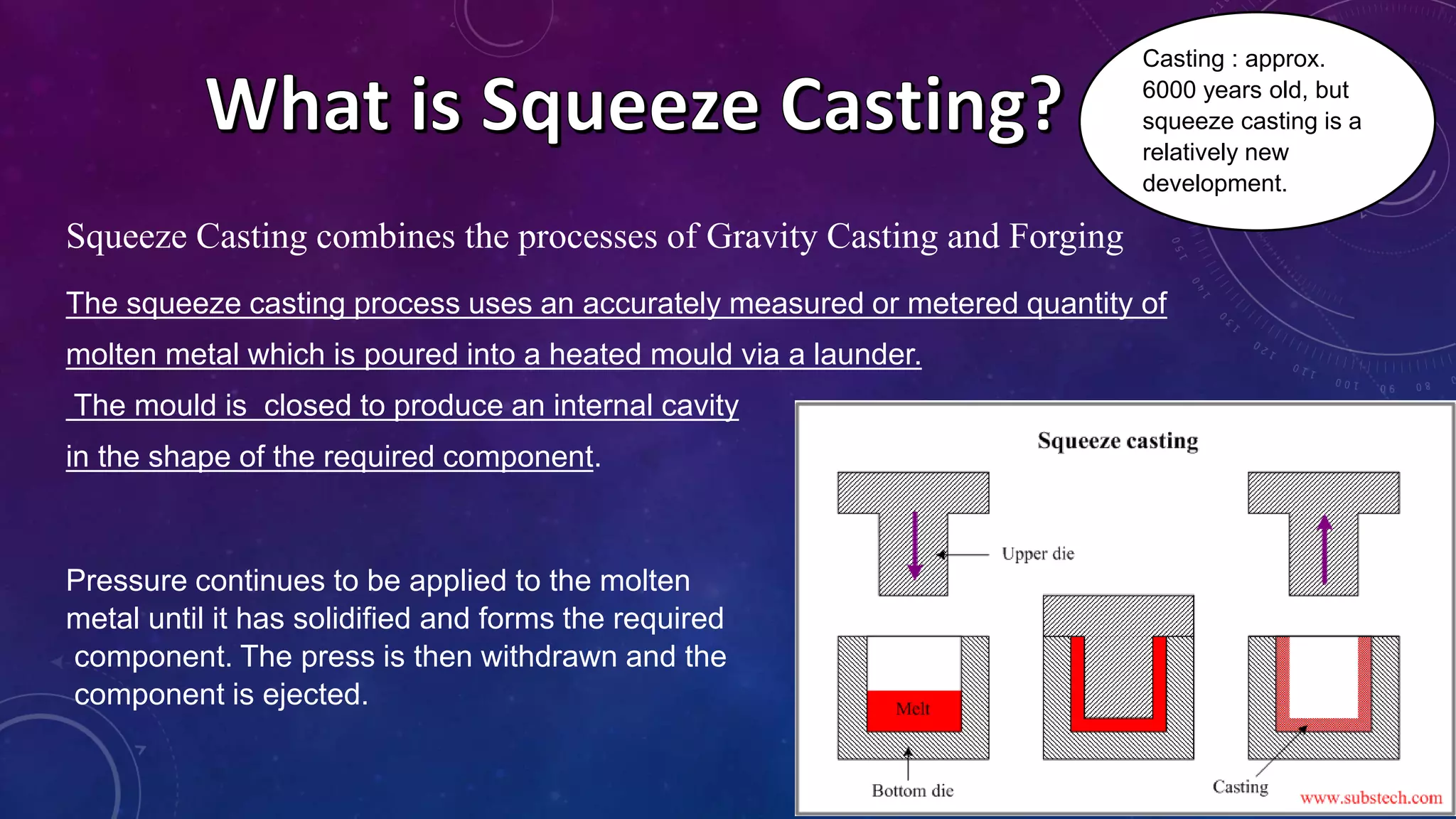

Squeeze casting is a combination of casting and forging that involves pouring molten metal into a pre-heated mold. Pressure is then applied via a hydraulic cylinder to push the molten metal into contact with the mold surfaces. This applied pressure continues until the metal solidifies, resulting in a component with a fine-grained microstructure, reduced porosity and cracks, and a smooth finish. Squeeze casting is well-suited for producing complex, high-strength light alloy components in large volumes for applications like automotive parts.