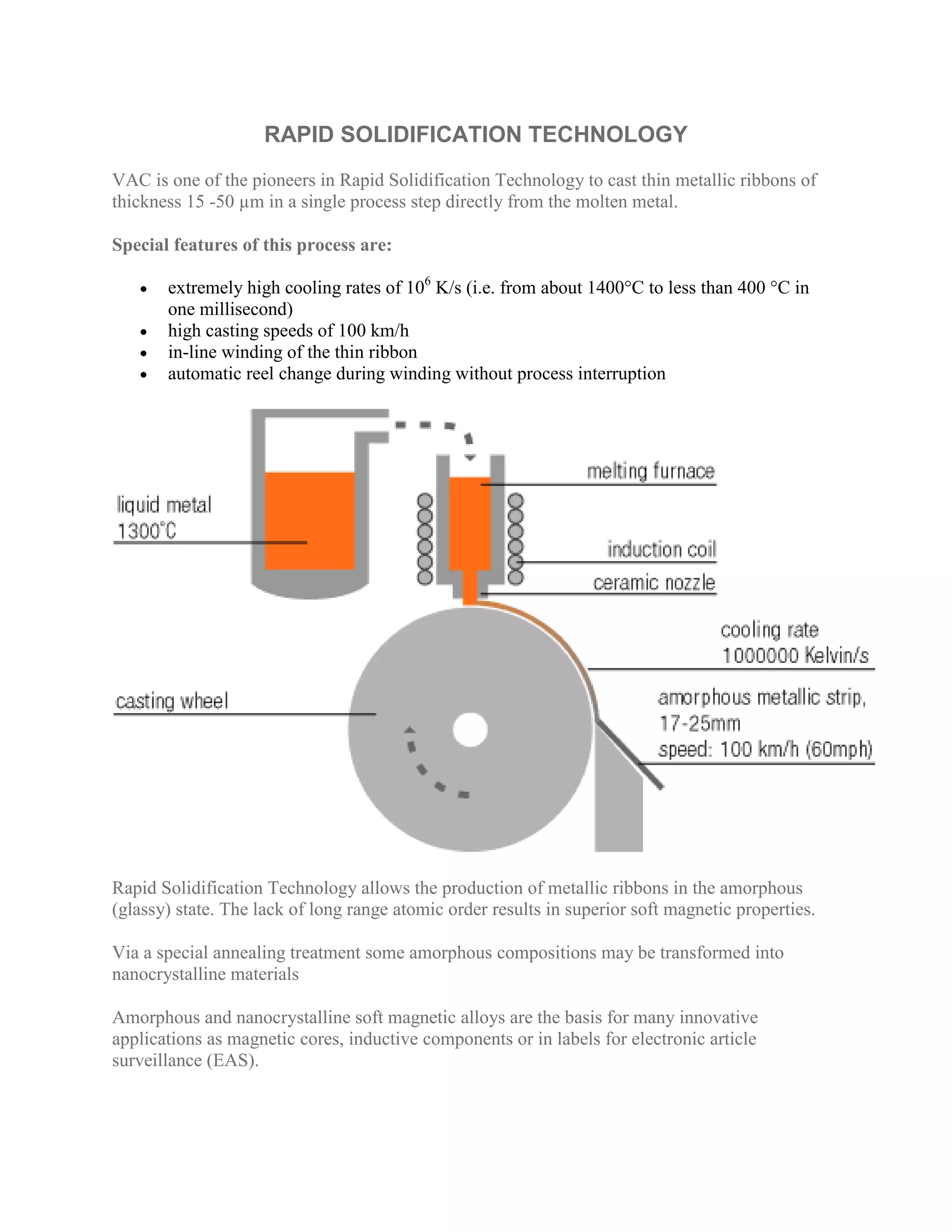

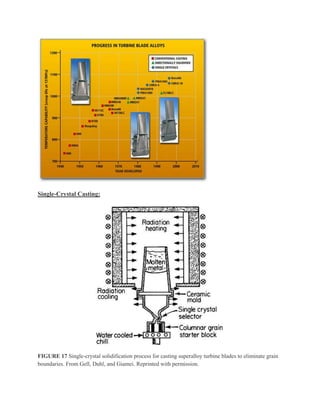

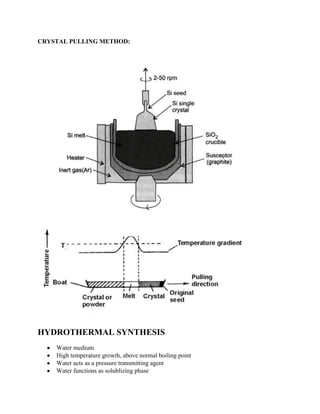

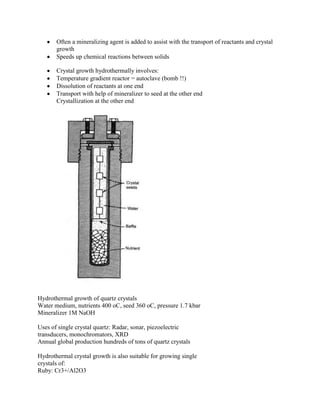

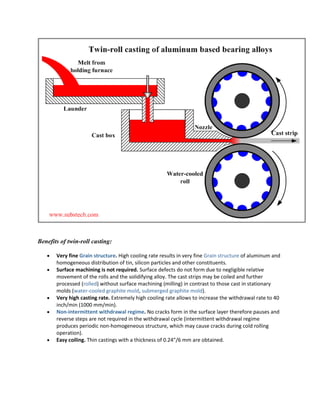

VAC uses rapid solidification technology to cast thin metallic ribbons from molten metal with extremely high cooling rates of 106 K/s, high casting speeds of 100 km/h, and automatic reel changing during winding. This allows the production of amorphous or nanocrystalline soft magnetic alloys with superior properties for applications such as magnetic cores and inductive components. Various single crystal growth methods are used to eliminate grain boundaries, including floating zone, Czochralski crystal pulling, and hydrothermal synthesis using water as a mineralizing agent. Twin-roll and twin-belt casting are continuous casting methods that produce thin strips with fine grain structure and high casting rates.