The document discusses continuous casting of steel and defects that can occur during the continuous casting process. It provides details on:

- Continuous casting involves delivering liquid metal into a water-cooled copper mold where the cast section is formed and then continuously withdrawn for further solidification. More than 50% of current steel production is continuously cast.

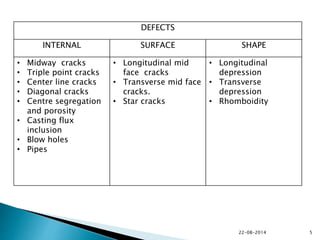

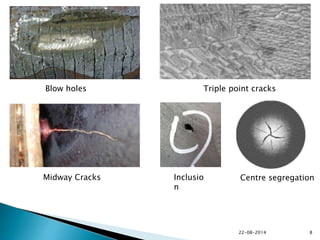

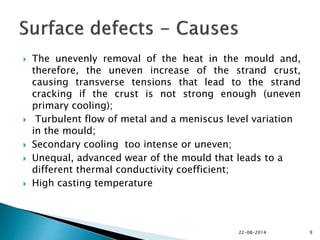

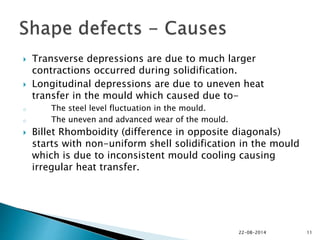

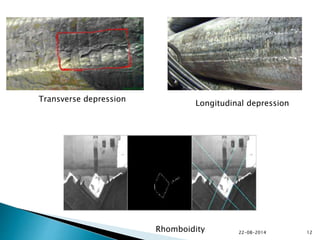

- Defects originate from factors like mold oscillation, mold flux, segregation, and phase transformations. Common defects include cracks, blowholes, inclusions, segregation, and pipes.

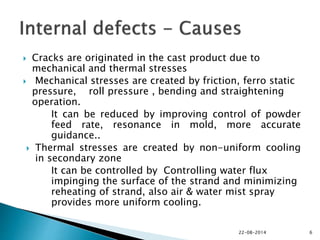

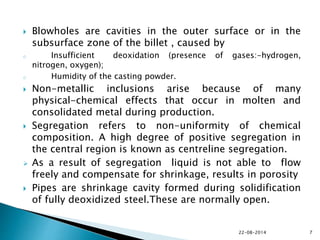

- Cracks are caused by mechanical and thermal stresses during casting and processing. Blowholes are caused by insufficient deoxidation or humidity. Inclusions arise from physical-chemical effects