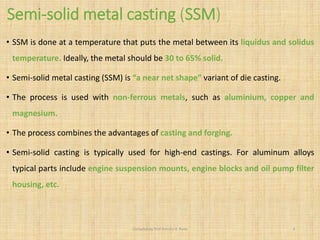

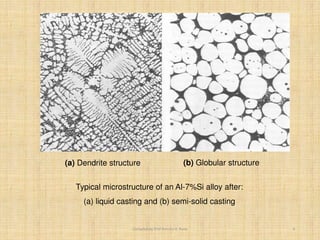

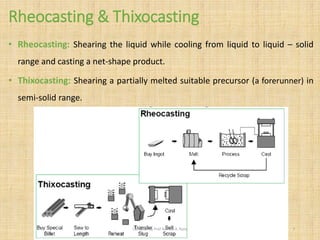

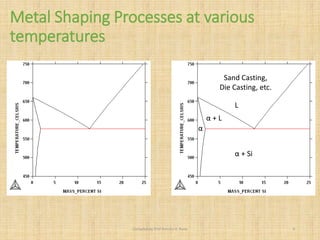

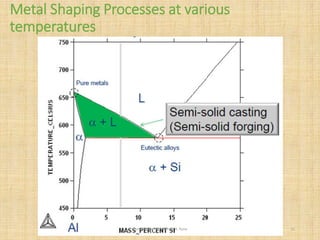

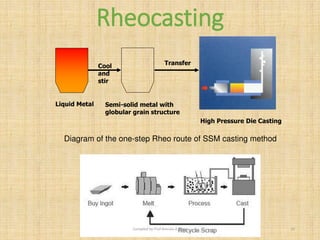

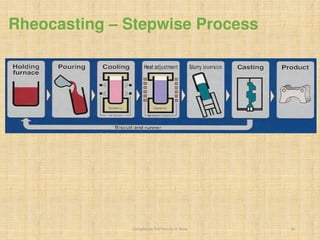

Semi-solid metal casting (SSM) involves processing metals between their liquidus and solidus temperatures, when they are partially solidified. This allows for modifying the dendritic microstructure and improving mechanical properties compared to fully liquid casting. SSM techniques include thixocasting, which uses pre-cast semi-solid billets that are reheated and injected into dies, and rheocasting, where the liquid metal is sheared as it cools through the semi-solid range. SSM offers advantages over traditional casting like reduced porosity and finer microstructures, making it suitable for high-strength automotive and machine components.