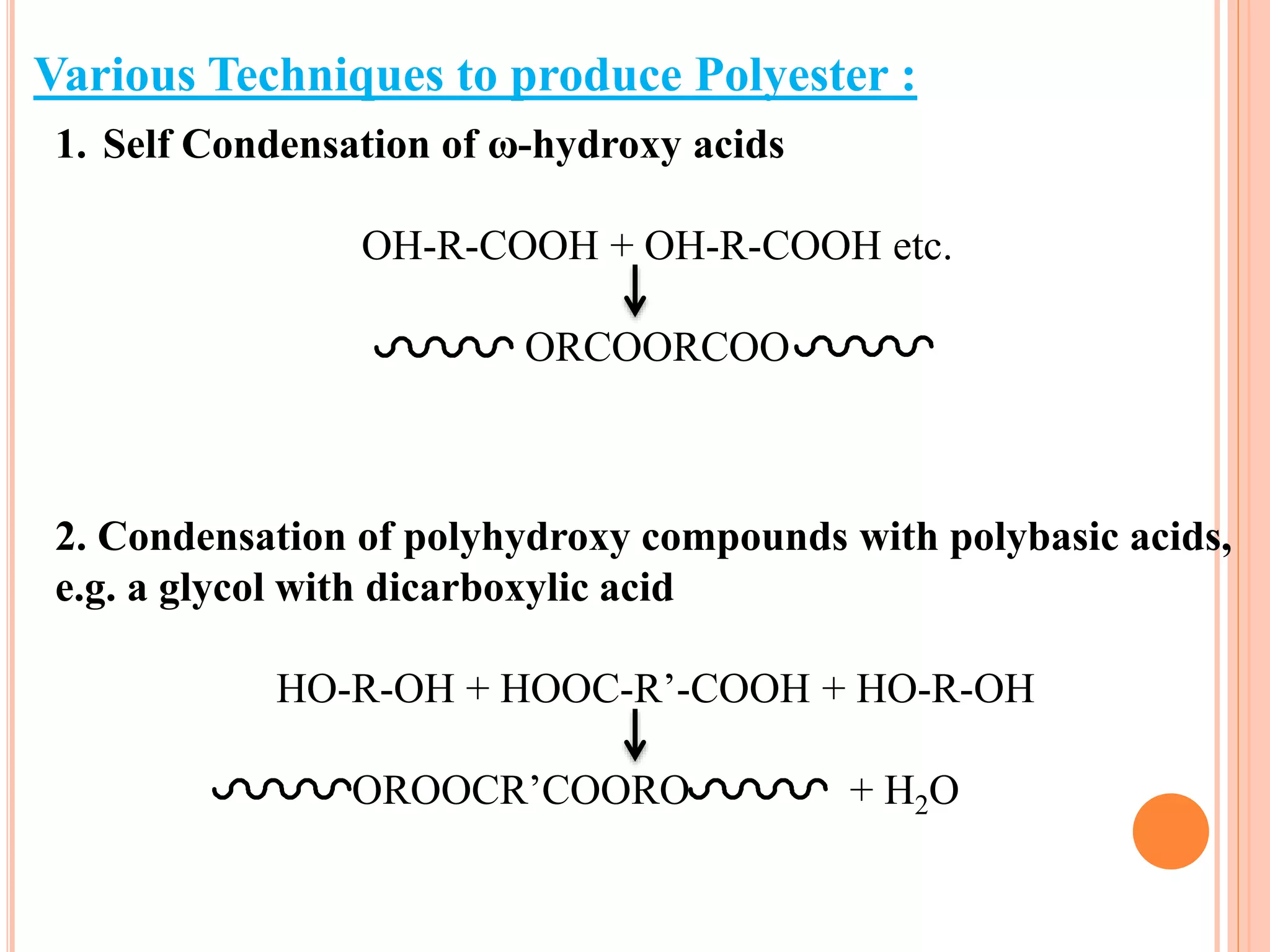

Polyester can be produced through various polymerization techniques such as self-condensation, condensation of polyhydroxy compounds with polybasic acids, ester exchange, and ring opening of lactones. Polyester has properties including susceptibility to hydrolysis, proton acceptor ester groups, and increased flexibility. Unsaturated polyester resins are produced from glycols and diacids and provide sites for cross-linking. Polyethylene terephthalate is a widely used polyester produced through ester exchange and polycondensation. It has applications as fibers, films, and bottles. Other polyesters include polybutylene terephthalate and aromatic polyesters.

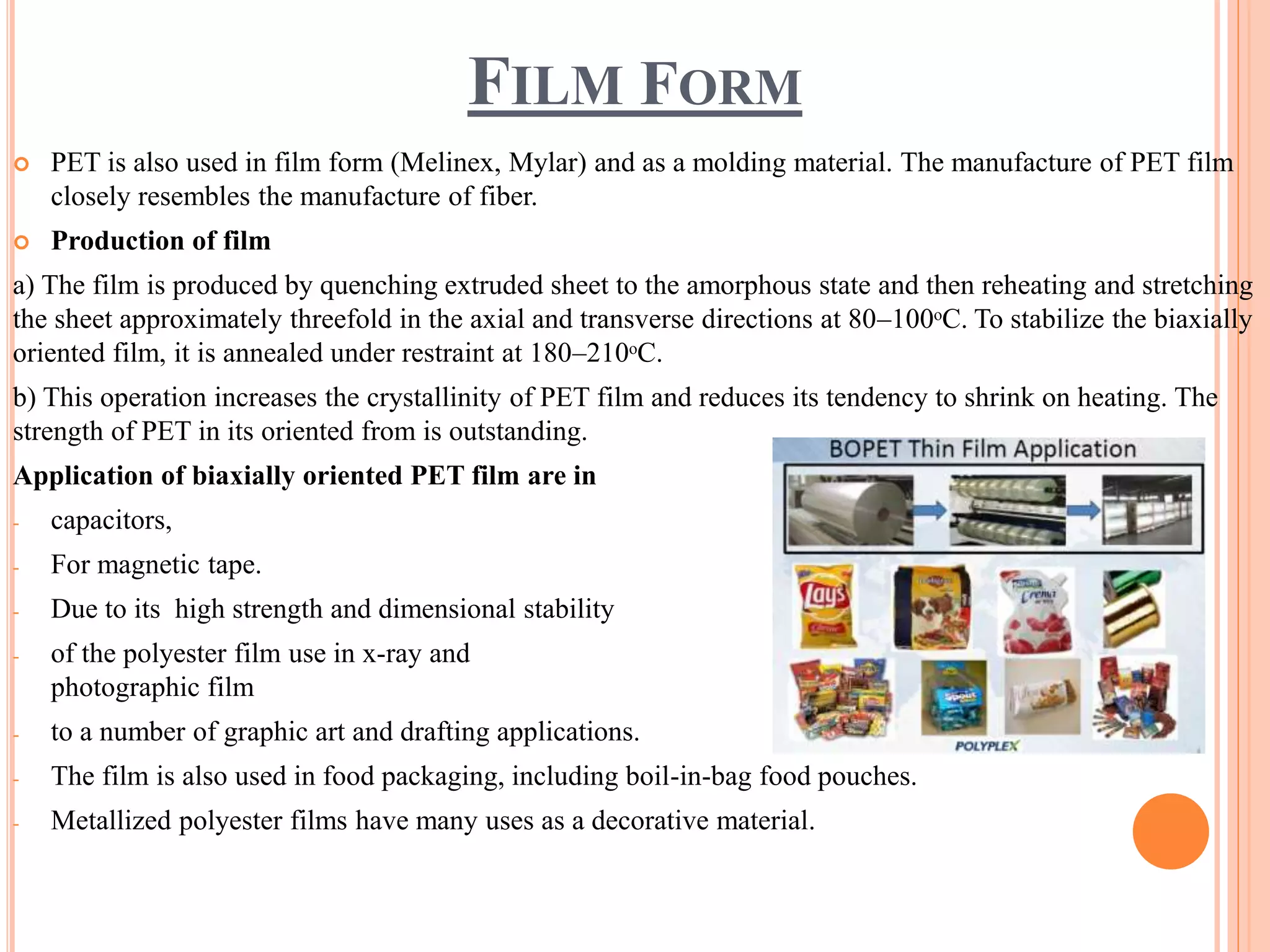

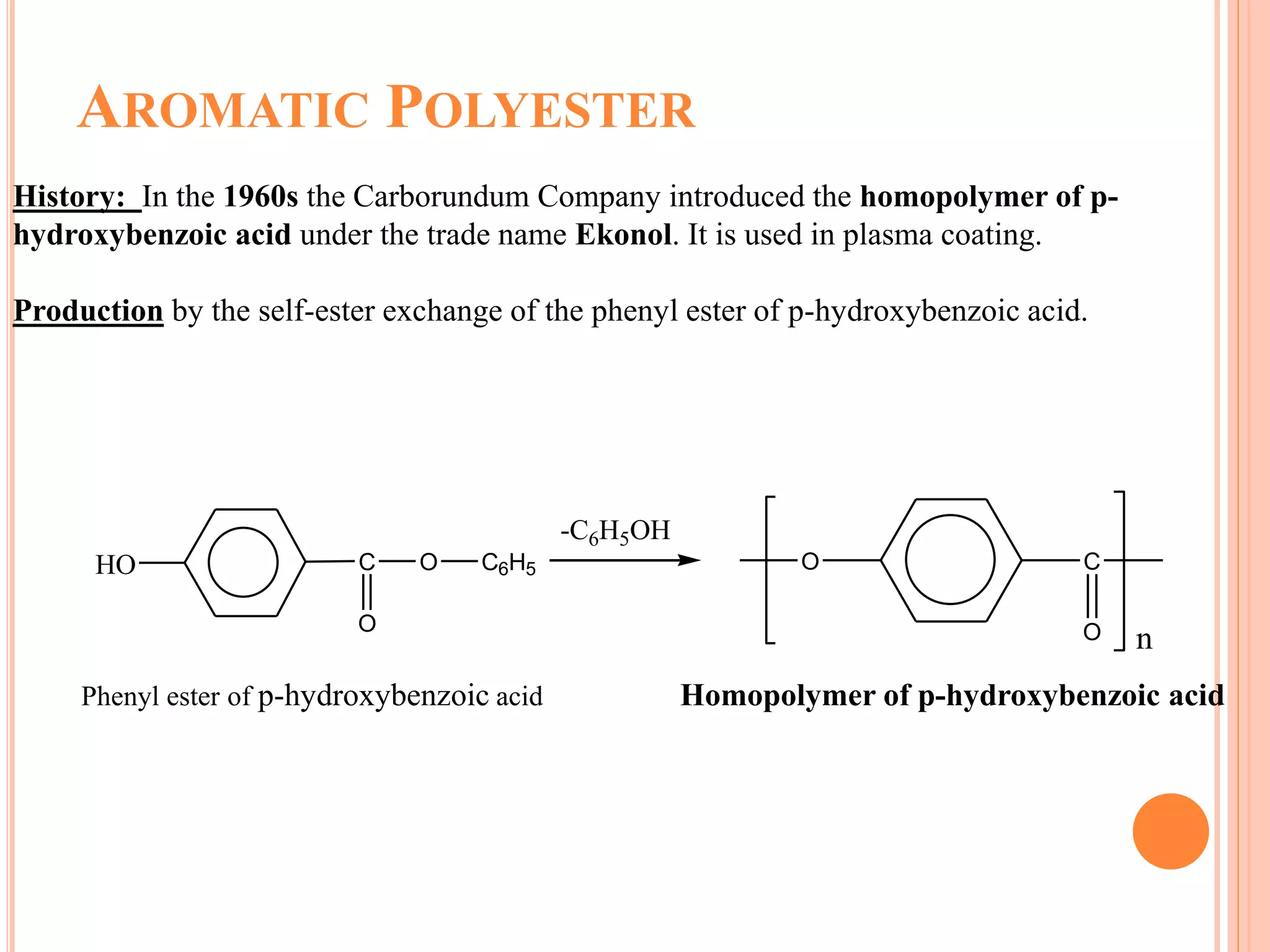

![COMMERCIAL ROUTES

Dimethyl terephthalate (DMT) is reacted with excess ethylene

glycol (mole ratio 1:2.1–2.2) at 150ᵒC. The output of the process is

bis(hydroxyethyl) terephthalate (BHET).

The pre-polymerization step (250–280ᵒC, 2–3 kPa) follows in which

BHET is polymerized to a degree of poymerization (DP) of up to 30.

The next step is the polycondensation process where the DP is further

increased to 100 by heating under vacuum, the process conditions

being 280–290ᵒC and 50–100 Pa.

Up to this stage, PET (poly ethylene terephthalate )is suitable for

applications that do not require high molecular weight or high intrinsic

viscosity [η], such as fibers and sheets.

Solid-state polymerization is used to further increase the DP to 150.

The operating conditions are 200–240ᵒC at 100 kPa and 5–25 h.

Ester exchange and Polycondensation](https://image.slidesharecdn.com/polyestercorrected-161204164727/75/Polyester-A-Speciality-Polymer-21-2048.jpg)

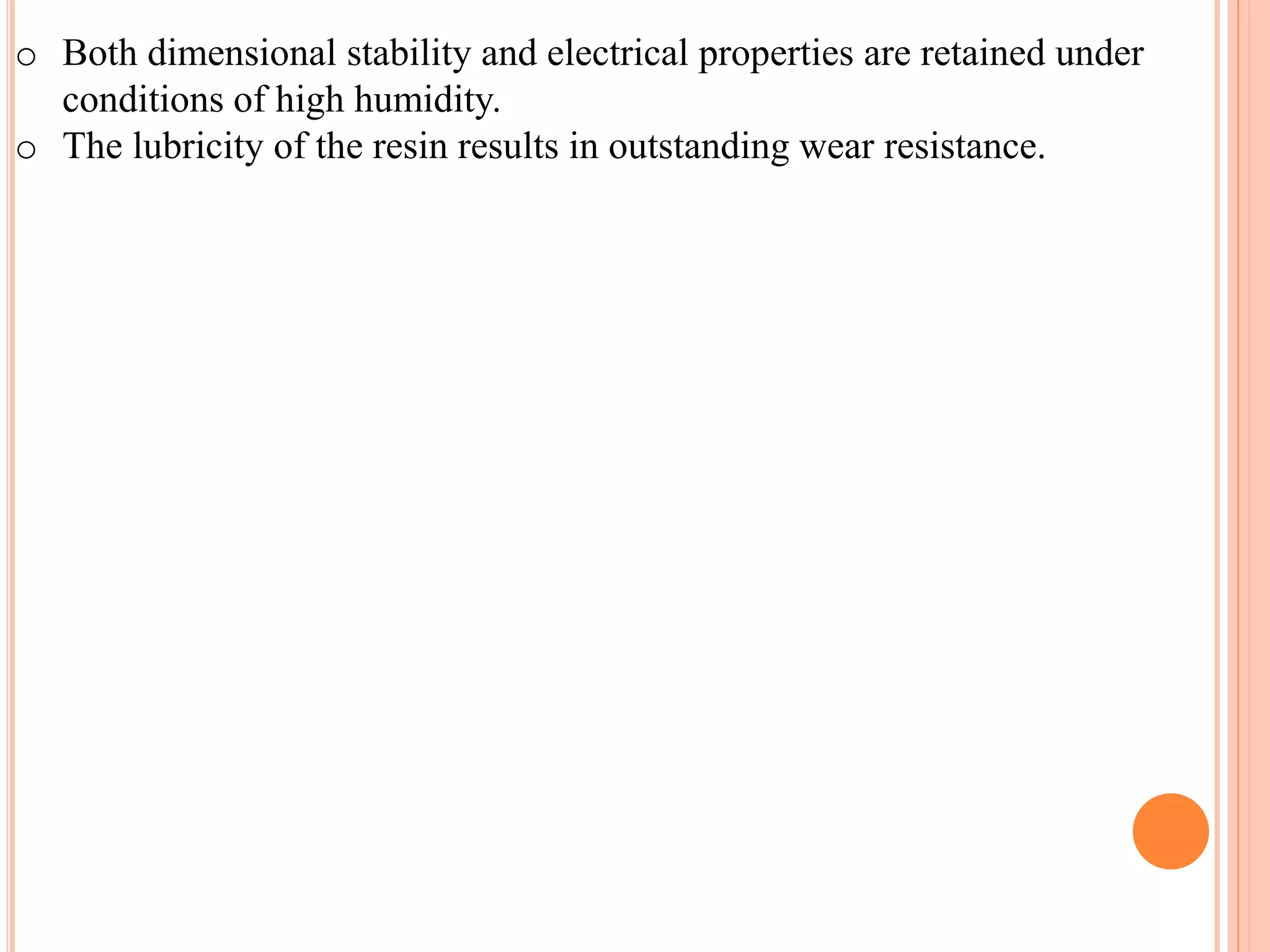

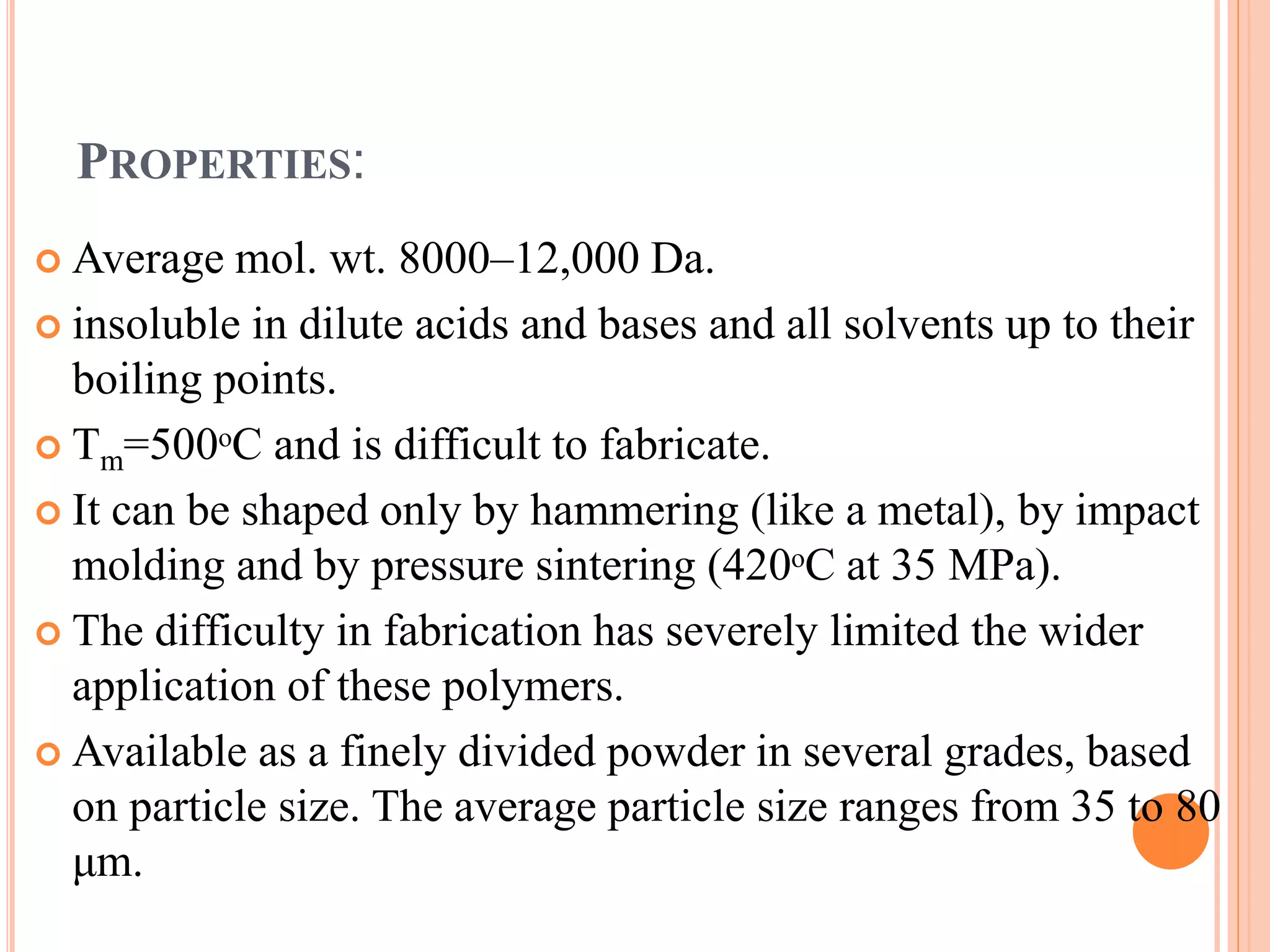

![PROPERTIES

Virgin PET is produced at different specifications because

different applications require different properties.

Examples of intrinsic viscosity [η] for different applications are

a) recording tape 0.60,

b) carbonated drink bottles 0.73–0.81, and

c) industrial tire cord 0.85 dl gˉ 1.

PET granules can be processed in many ways depending on

application and final product requirements.](https://image.slidesharecdn.com/polyestercorrected-161204164727/75/Polyester-A-Speciality-Polymer-22-2048.jpg)