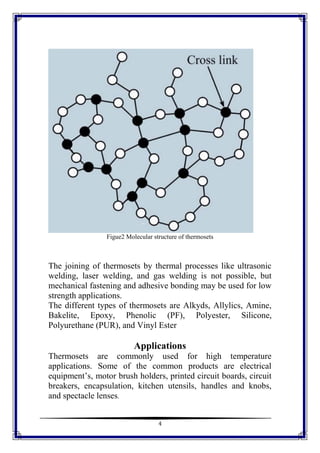

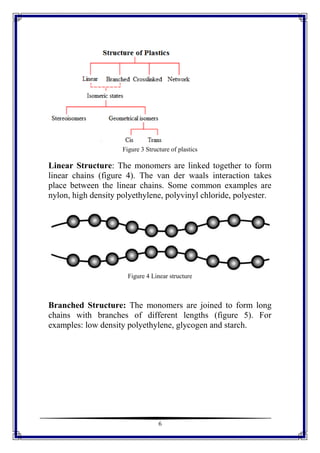

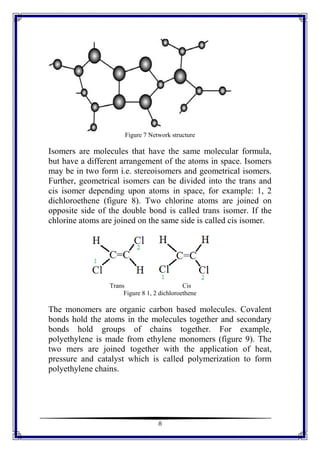

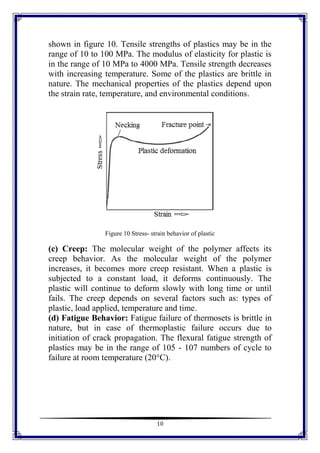

Thermoplastic and thermosetting polymers can be differentiated based on their molecular structure and response to heat. Thermoplastics soften when heated and harden again when cooled, allowing them to be repeatedly melted and reshaped. Thermosets permanently harden when heated and cannot be remelted or reshaped. Some key applications of thermoplastics include car dashboards and toys, while thermosets are commonly used in electrical equipment and circuit boards due to their high heat resistance.