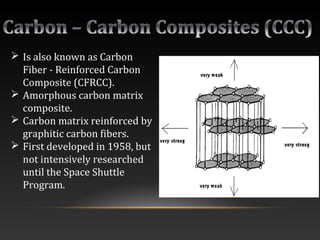

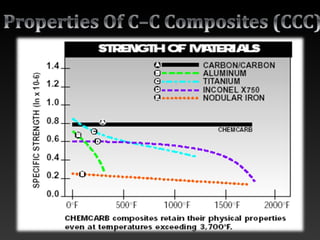

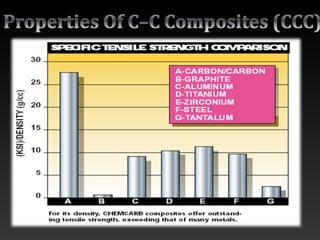

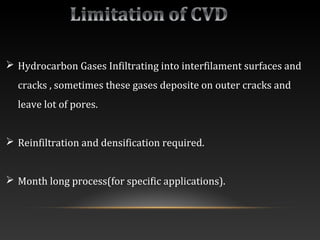

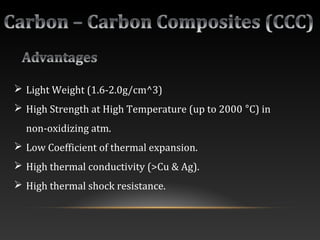

Carbon-carbon composites are composites with carbon fiber reinforcement and a carbon matrix. They offer high strength and can withstand very high temperatures up to 3000°C. The fibers and matrix are both carbon, resulting in low density, high thermal conductivity, and strength retention even at elevated temperatures. However, carbon-carbon composites also have some limitations like high fabrication costs and poor oxidation resistance.