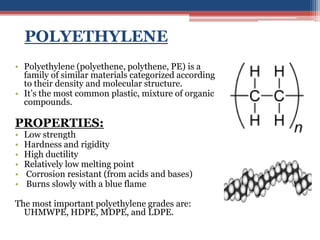

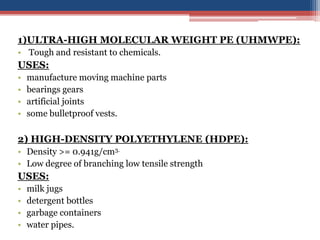

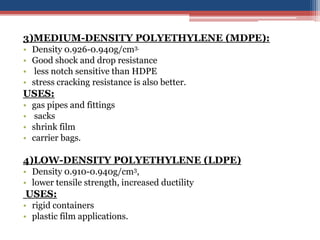

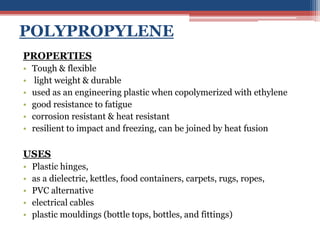

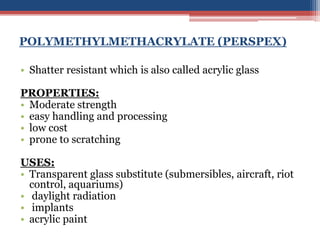

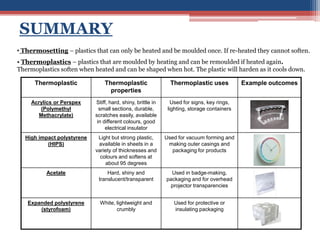

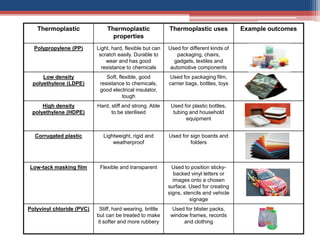

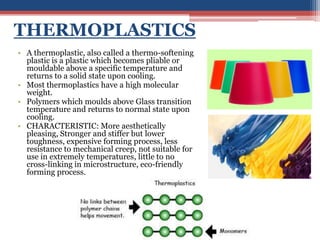

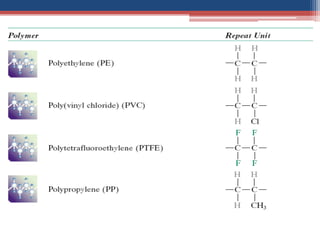

This document discusses various thermoplastics, their properties, and common uses. Thermoplastics are plastics that can be remelted and remolded if heated again. Examples discussed include polyvinyl chloride (PVC), commonly used in pipes, cables, and clothing; polyethylene, with applications in bottles, bags, and films; and polypropylene and polymethyl methacrylate (Perspex), both used in a variety of products and packaging.

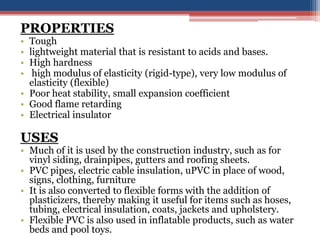

![POLYVINYL CHLORIDE (PVC)

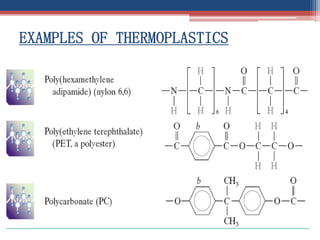

• Polyvinyl chloride is produced by polymerization of the vinyl

chloride monomer (VCM)

• PVC comes in two forms, rigid -RPVC (for construction in

pipe and in doors and windows) and are made more flexible

by addition of plasticizers (phthalates). [Add ease of work,

used for cables, lowers glass transition temperature, increased

flexibility and durability]](https://image.slidesharecdn.com/thermoplastics-180804144023/85/Thermoplastics-10-320.jpg)