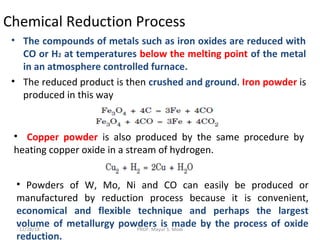

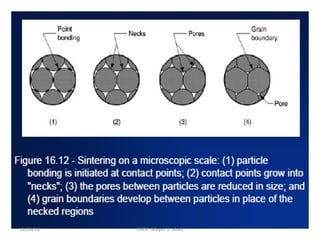

Powder metallurgy is a process for manufacturing parts from metal powders by compacting and sintering. Key steps include producing metal powders through methods like atomization or chemical reduction, blending powders and lubricants, compacting the blended powder in a die under pressure to form a green compact, and sintering the compact at high temperatures to bond the powder particles. The sintered parts have properties that cannot be achieved through conventional manufacturing and the process allows for high precision and low waste production of simple parts.