Here are the key steps to solve this example:

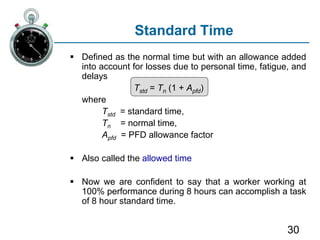

(a) Standard time = Normal time * (1 + PFD allowance factor)

= 3.23 min * (1 + 0.15) = 3.23 * 1.15 = 3.72 min

(b) Irregular element time per cycle = Normal time / Frequency

= 1.25 min / 5 cycles = 0.25 min

(c) Standard time including irregular element

= Regular cycle time + Irregular element time per cycle

= 3.72 min + 0.25 min = 3.97 min

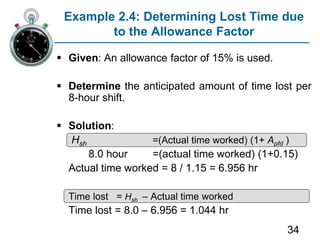

(d) In an 8-hr shift at standard time:

Units produced = (Shift time / Standard time)