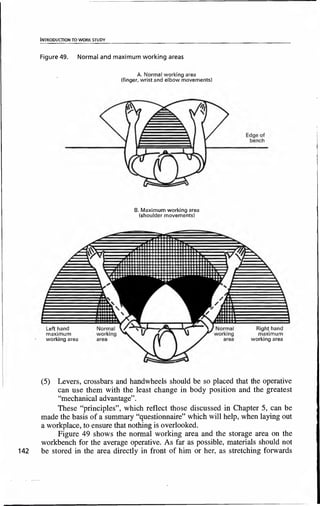

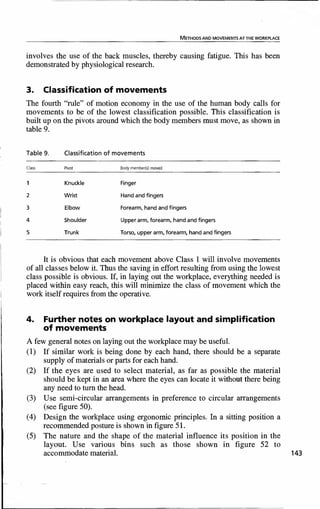

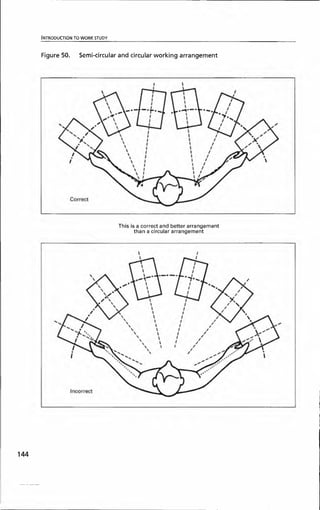

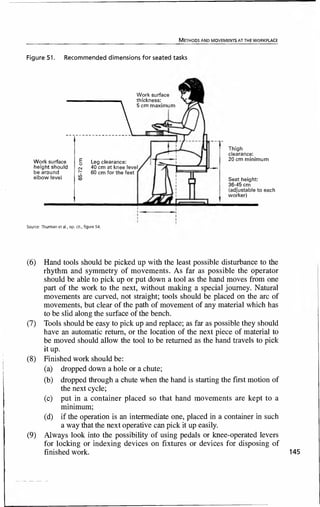

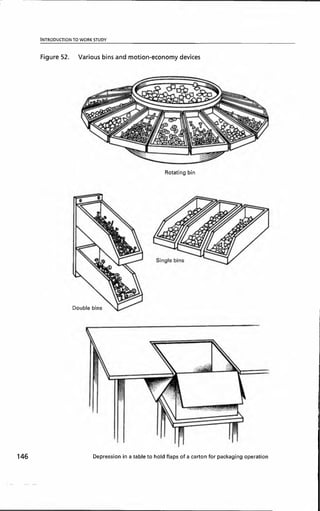

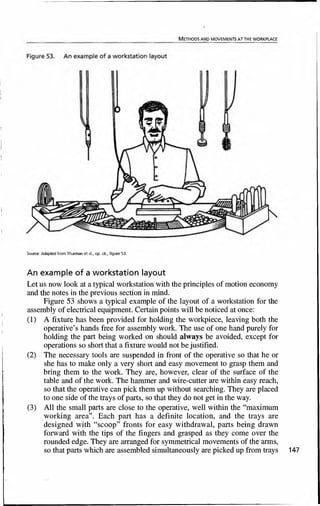

This document discusses principles of motion economy and efficient workplace design. It begins by outlining general considerations for studying individual worker movements at a workplace. It then discusses principles of motion economy related to: using the human body efficiently, arranging the workplace effectively, and designing tools and equipment to minimize fatigue. Specific guidelines are provided for each of these principles. The document also discusses classifying types of movements, further notes on optimizing workplace layout and tool placement, designing jigs/fixtures, and ensuring machine controls are easy to use. An example workplace layout is analyzed showing how it applies motion economy principles.