Embed presentation

Downloaded 79 times

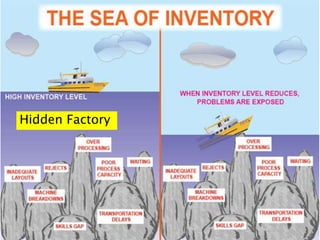

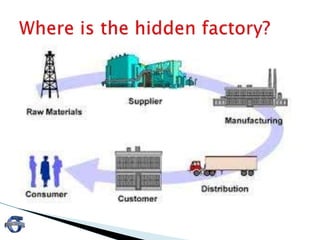

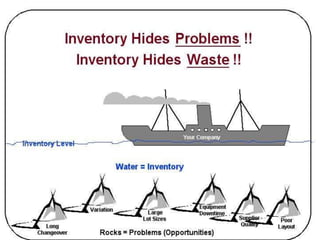

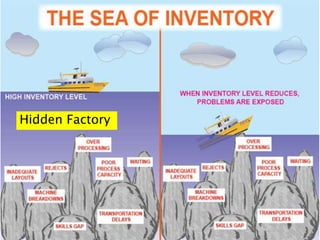

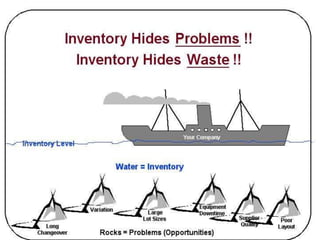

The document discusses strategies for optimizing production efficiency by reducing non-value added activities, which typically account for 95% of lead time. It highlights the importance of cross-functional training to alleviate bottlenecks and improve workflow balance. By focusing on value-added processes, organizations can enhance customer satisfaction and profitability while minimizing material waste and costs.