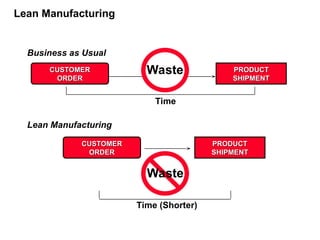

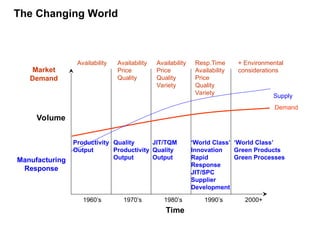

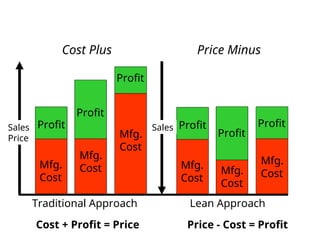

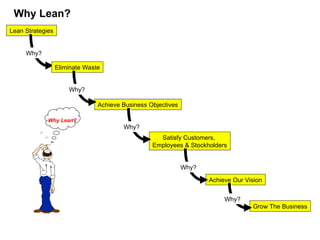

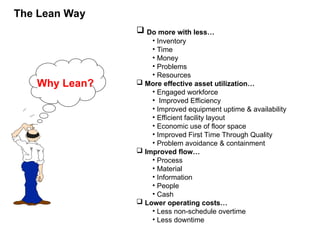

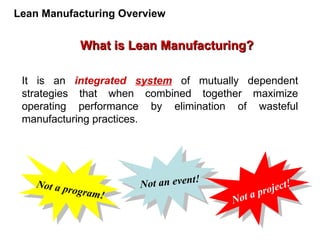

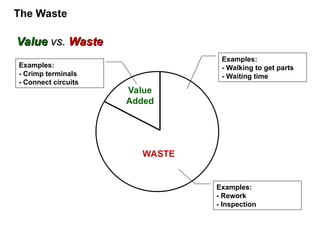

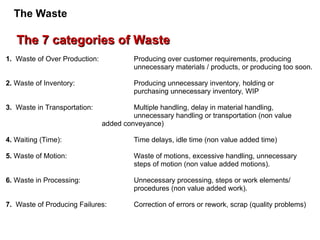

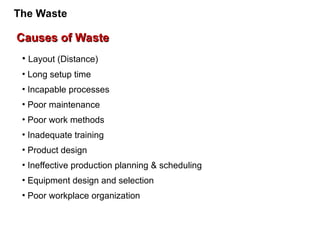

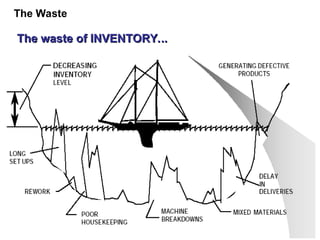

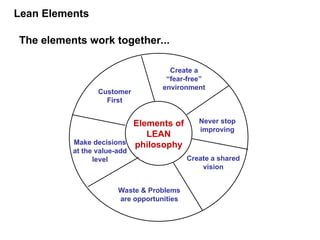

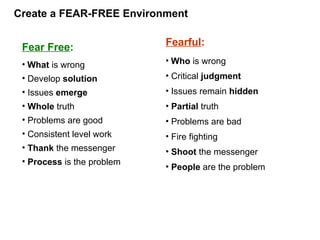

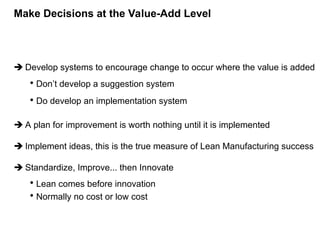

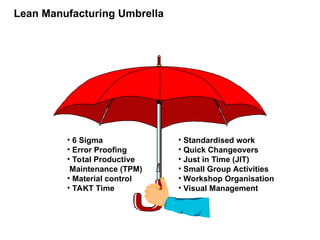

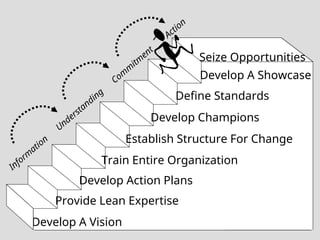

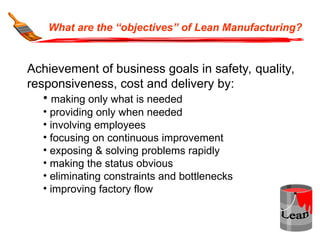

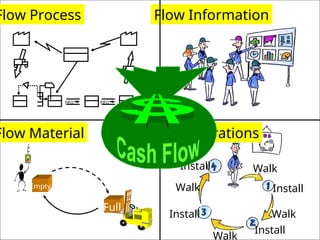

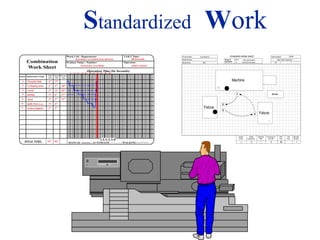

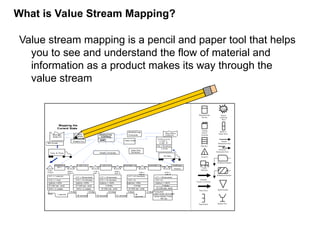

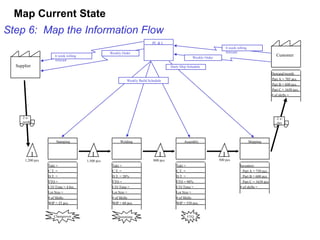

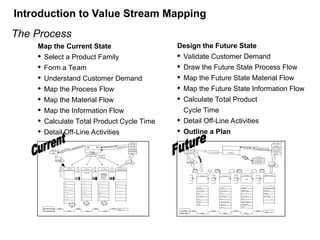

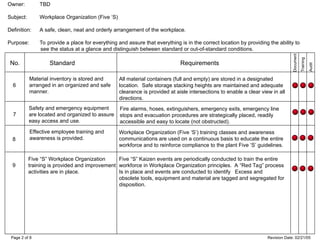

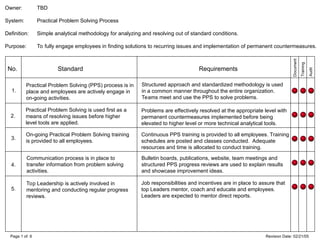

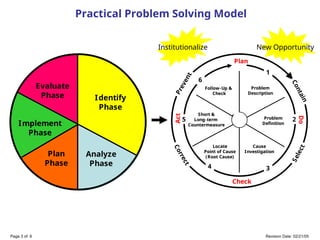

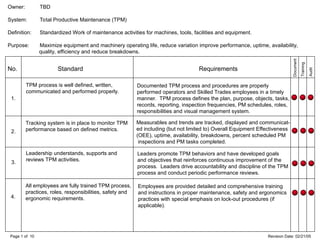

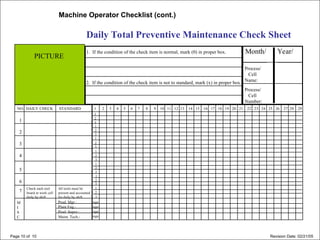

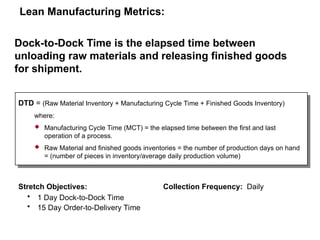

The document provides a comprehensive overview of lean manufacturing, explaining its philosophy focused on eliminating waste and enhancing productivity. It outlines the objectives of lean manufacturing, including improving quality, reducing costs, and increasing customer satisfaction through various metrics and strategies. Key elements discussed include waste identification, standardized work, value stream mapping, and the importance of a culture centered on continuous improvement.