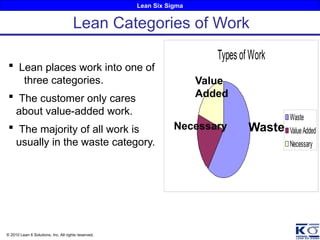

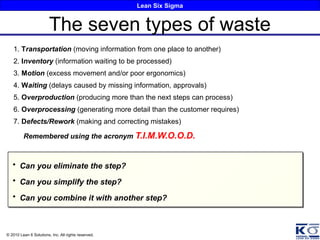

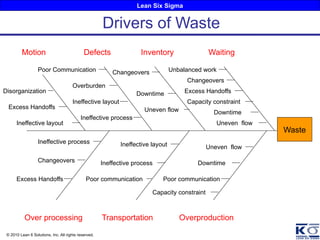

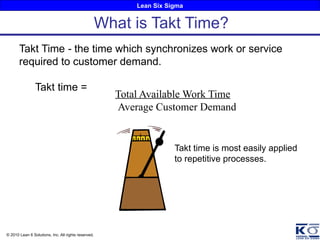

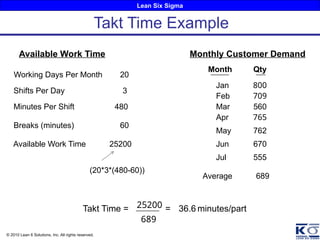

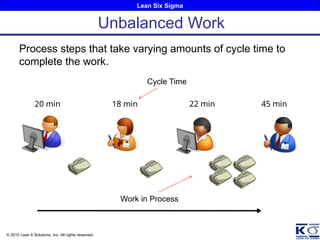

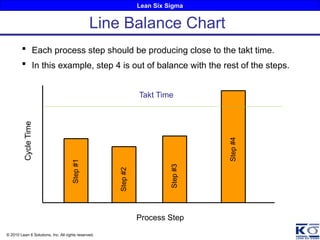

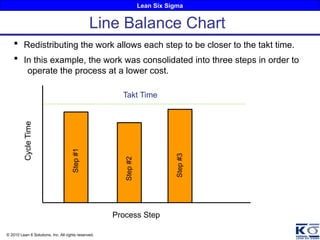

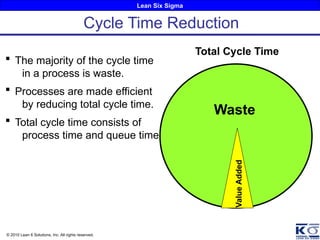

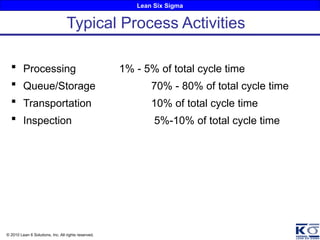

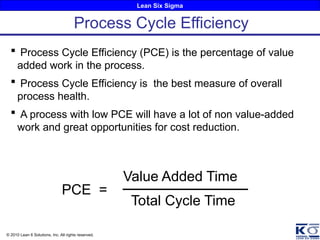

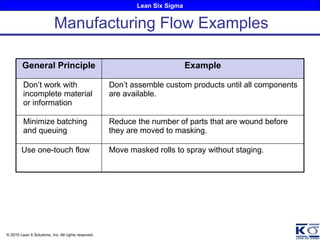

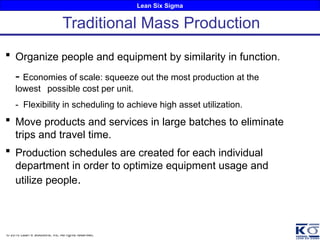

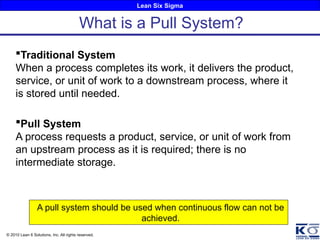

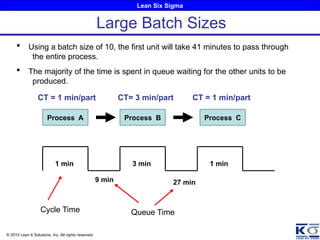

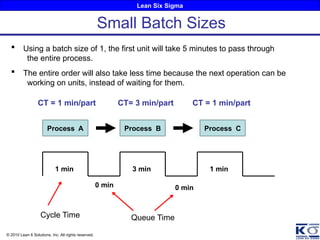

The document explores the principles and practices of Lean Six Sigma, which categorizes work into value-added, necessary, and waste categories, focusing on waste elimination to enhance efficiency. It details seven types of waste, such as overproduction and defects, and emphasizes the importance of processes like Just-In-Time and Pull Systems to streamline operations and reduce excess inventory. Additionally, it highlights the significance of continuous flow and cycle time reduction to optimize production processes and meet customer demand efficiently.