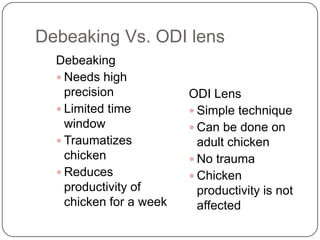

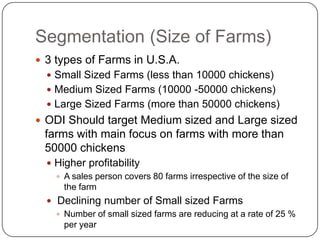

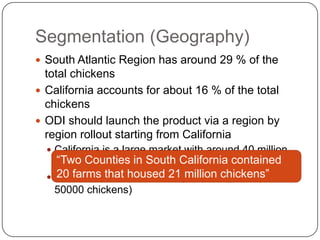

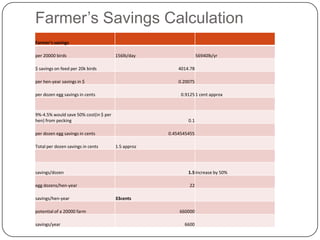

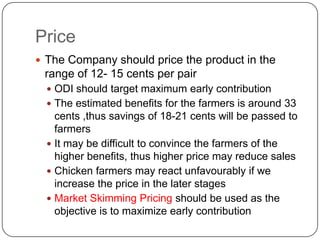

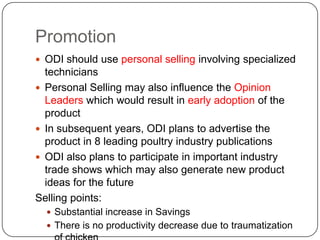

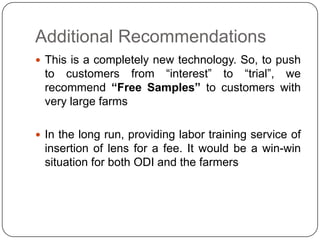

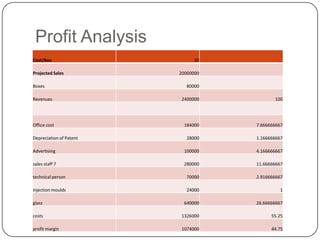

Optical Distortion Inc has developed a contact lens to reduce vision in poultry chickens to improve their behavior. They have tested the lens on farms in California and Oregon. The document discusses transforming the lens from a product idea to a branded product concept to launch in the market. It analyzes segmenting the market by farm size and geography, with a focus on medium and large farms over 50,000 chickens in California initially. It also discusses pricing the lens at 12-15 cents each, promoting through sales representatives and trade shows, and the potential cost savings and profits for farmers and the company.