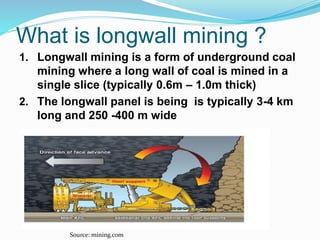

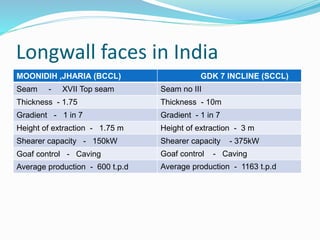

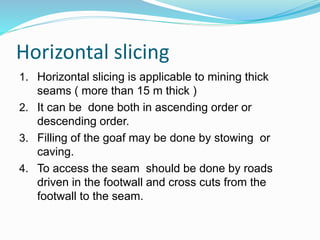

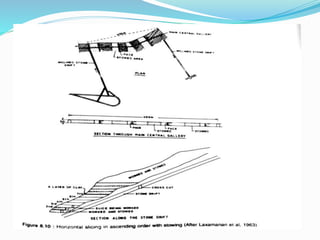

The document discusses longwall mining, a method of underground coal mining where a long wall of coal is mined in a single slice, and highlights its application in India, including significant historical developments and current practices. It elaborates on multislicing techniques, particularly horizontal slicing for thick seams, along with methods of longwall advancing and retreating. The document also provides examples of mining operations in India and references for further reading.