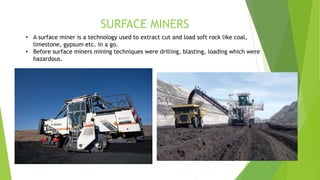

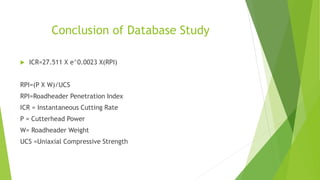

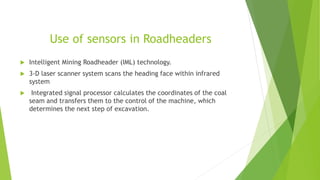

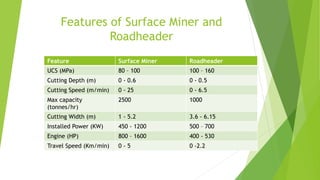

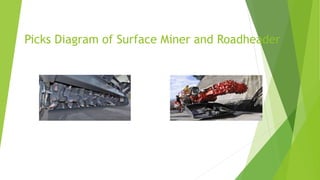

This presentation summarizes surface miners and roadheaders, and prospects for combining their capabilities. Surface miners are effective for soft rock but cannot cut hard rock. Roadheaders can excavate soft to medium rock, and with modifications, hard rock as well, but are more expensive to operate and maintain. The presentation explores using sensors and adaptive technologies to allow surface miners to cut harder rocks, and compares key specifications and applications of the two methods. It concludes by discussing using liquids or lasers to soften hard rocks and allow a single machine to excavate a wider range of materials.