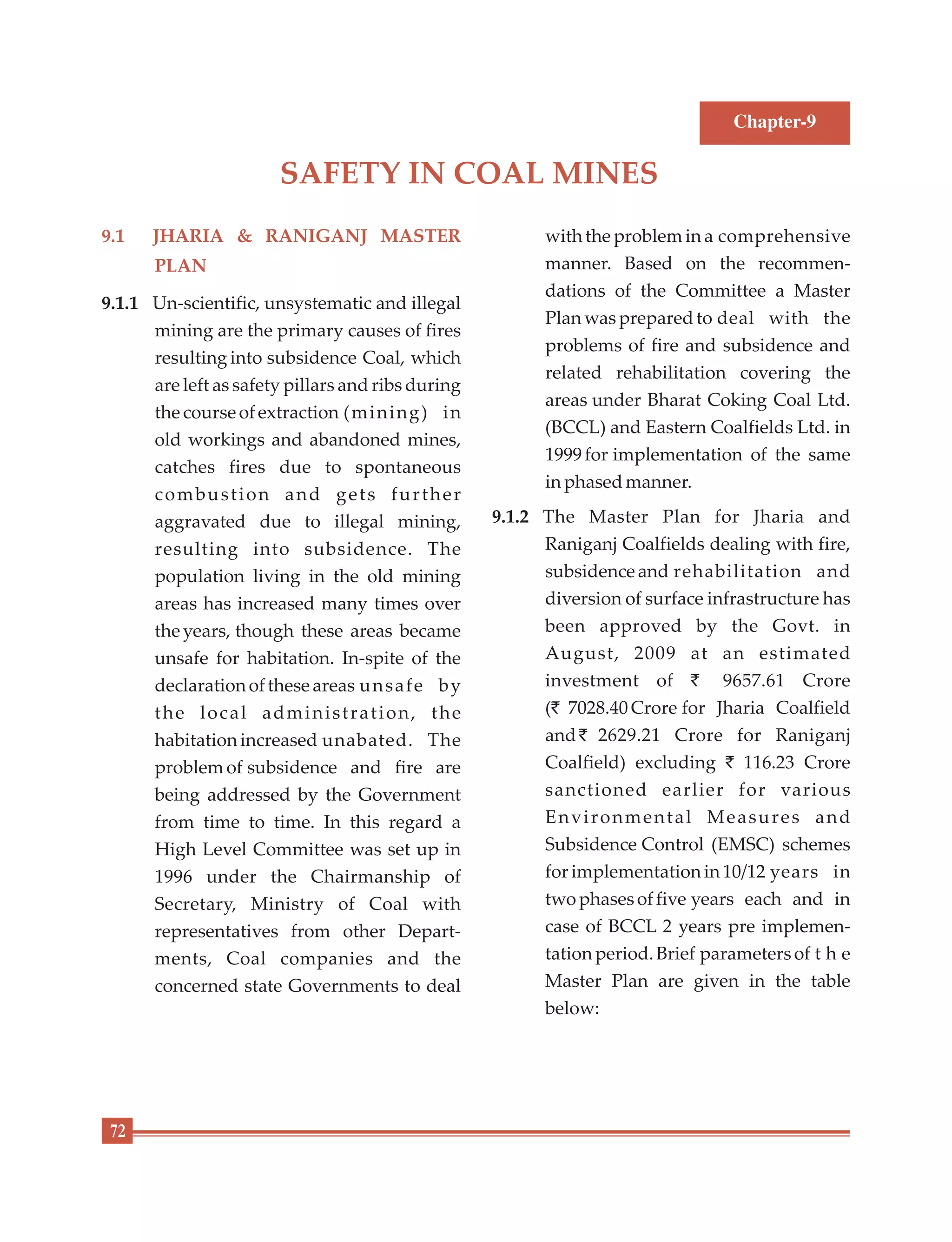

The document summarizes the master plan for addressing fire, subsidence and rehabilitation issues in the Jharia and Raniganj coalfields in India. Key points:

1) The master plan was approved in 2009 with an estimated budget of 9657.61 crore rupees (7028.40 crore for Jharia and 2629.21 crore for Raniganj) to address fires, subsidence and relocate populations from unsafe areas over 10-12 years.

2) It identifies the Jharia Rehabilitation & Development Authority and Asansol Durgapur Development Authority as implementing agencies for rehabilitation.

3) Over 65% of demographic surveys for relocating affected people